|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 5-2410-237-23

TORQUE DIVIDER REPAIR - CONTINUED

0245 14

INSPECTION - CONTINUED

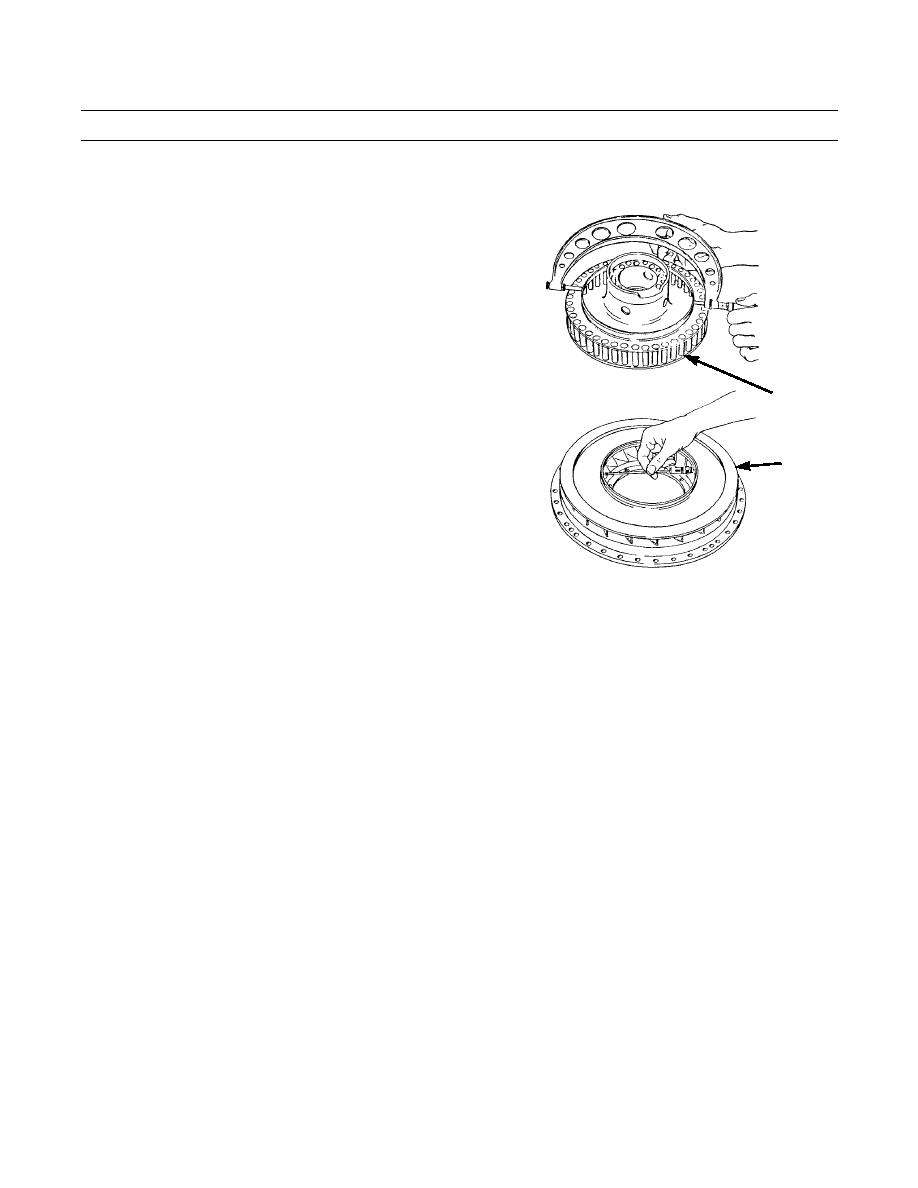

2.

Check clearance between impeller and stator as follows:

a.

Use an outside diameter micrometer to measure

diameter of stator flange at four points on stator

(19). Record lowest reading.

b.

Use an inside diameter micrometer to measure

inside diameter of outer edge of flange on impel-

ler (16) at four points. Record highest reading.

c.

The clearance across diameters between impeller

and stator is the difference between the highest

reading on impeller and the lowest reading on

stator. The clearance must be 0.009-0.015 in.

19

(0.23-0.38 mm). Maximum permissible clear-

ance across diameters is 0.024 in. (0.61 mm).

16

421-0191

3.

Clearance between new turbine and housing across diameter should be 0.040-0.060 in. (1.02-1.52 mm).

4.

Maximum permissible clearance between worn turbine and housing across diameter is 0.090 in. (2.29 mm).

5.

Outside diameter of new shaft (bearing area) should be 1.7495 0.0005 in. (44.437 0.013 mm).

6.

Inside diameter of bearings after installation should be 1.7400 0.0005 in. (44.196 0.013 mm).

7.

Inside diameter of bearings after installation should be 1.7400 0.0005 in. (44.196 0.013 mm).

0245 14-9

Change 1

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |