|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 5-2410-237-23

FUEL INJECTION PUMP MAINTENANCE - CONTINUED

0245 09

DISASSEMBLY

CAUTION

Keep all components clean. Contaminants may cause rapid wear and shortened component life.

When the fuel injection pumps are disassembled, handle the parts carefully. Do not damage the sur-

faces of the plungers, the barrels or the caps. Any scratches will cause leakage inside the fuel injection

pump.

The plunger and the barrel for each pump are sets. Do not use the plunger of one pump in the barrel of

another pump. If one part is worn, install a complete new plunger and barrel assembly. Be careful

when placing the plunger into the bore of the barrel.

Do not remove gear from plunger. Gear and plunger are assembled and adjusted by the manufacturer.

Do not mix check valve assembly parts with parts from another chck valve assembly.

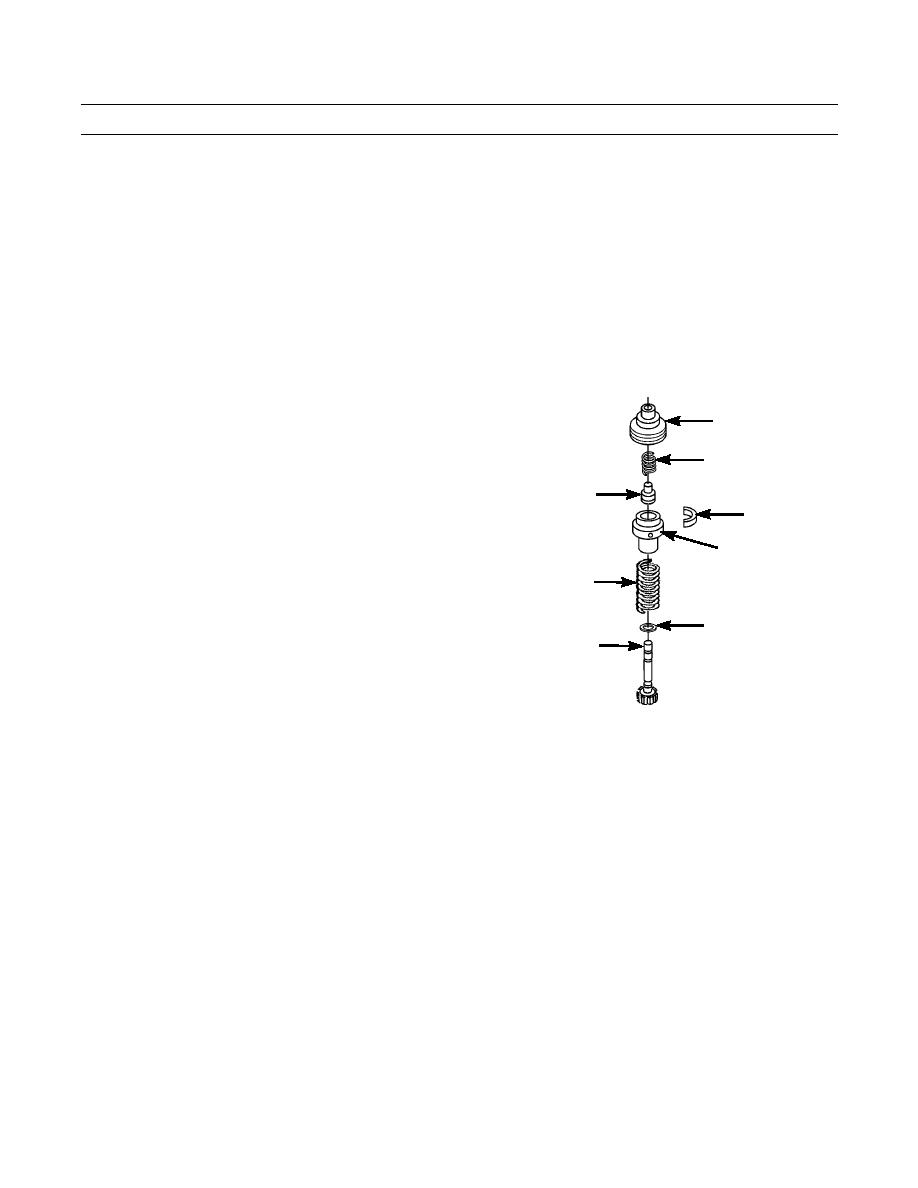

1.

Separate plunger (11) and washer (12) from barrel

(13) and spring (14).

16

2.

Remove washer (12) from plunger (11) and remove

spring (14) from barrel (13).

18

3.

Remove ring (15) and separate barrel (13) from cap

17

(16).

15

4.

Remove check valve assembly (17) and spring (18)

from cap (16).

13

14

12

11

421-0147

0245 09-3

Change 1

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |