|

|||

|

|

|||

|

Page Title:

CRANKSHAFT AND BEARINGS ASSEMBLY MAINTENANCE |

|

||

| ||||||||||

|

|

TM 5-2410-237-23

CRANKSHAFT AND BEARINGS ASSEMBLY MAINTENANCE

THIS WORK PACKAGE COVERS

Removal, Disassembly, Cleaning and Inspection, Assembly, Installation

INITIAL SETUP

Tools and Special Tools

Materials/Parts

Cleaning compound, solvent (Item 4, WP 0249 00)

Tool kit, general mechanic's (Item 122, WP 0250

Gage, bearing clearance (Item 44, WP 0249 00)

Shop equipment, machine shop (Item 107, WP

Oil, lubricating (Item 23, 24, 25 or 26, WP 0249 00)

Primer coating (Item 28, WP 0249 00)

Shop equipment, field maintenance (Item 177, WP

Rag, wiping (Item 29, WP 0249 00)

Sealing compound (Item 33, WP 0249 00)

Leg, puller (Item 162, WP 0250 00)

Tag, marker (Item 37, WP 0249 00)

Link, bearing lifting (Item 50, WP 0250 00)

Key (13)

Nut, plain hexagon (Item 163, WP 0250 00)

Oil seal and wear sleeve assembly (14)

Plate, mechanical puller (Item 166, WP 0250 00)

Seal (11)

Puller attachment, mechanical (Item 80, WP 0250

Sleeve bearing (6 and 10)

Wear sleeve (12)

Puller, crank pulley (Item 82, WP 0250 00)

Equipment Condition

Pump, hydraulic ram, hand driven (Item 193, WP

Flywheel housing removed (WP 0031 00)

Step plate, mechanical puller (Item 118, WP 0250

Front housing cover removed (WP 0245 05) (DO

NOT remove timing gears)

Pistons and connecting rods removed (WP 0245 04)

Lifting equipment, 500-lb capacity

CAUTION

Use caution to ensure components of cylinder block do not become contaminated. Keep work area clean.

Contamination of cylinder block components could result in premature engine failure.

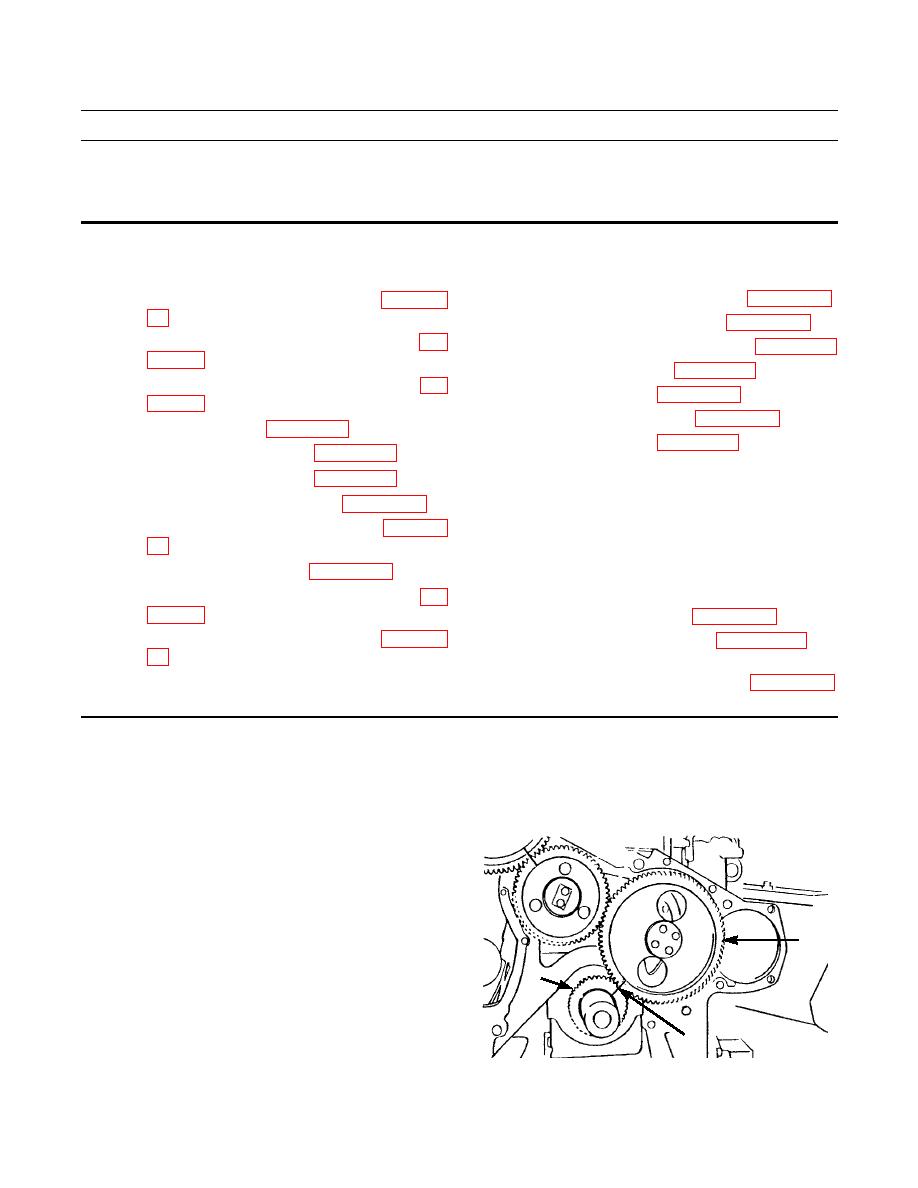

REMOVAL

1.

Verify that the mark on the bearing cap corresponds

with the mark on the cylinder block. If not, mark bear-

ing cap accordingly.

2.

Turn crankshaft until timing mark (A) on crankshaft

gear (1) is aligned with timing mark (A) on camshaft

gear (2).

2

1

A

421-0087

Change 1

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |