|

|||

|

|

|||

|

Page Title:

PRESSURE RELIEF VALVE TESTS |

|

||

| ||||||||||

|

|

TM 5-2410-237-23

HYDRAULIC SYSTEM TESTS - CONTINUED

0227 00

HYDRAULIC SYSTEM TEST PROCEDURES - CONTINUED

Table 7. Interpretation of Ripper Lift Circuit Drift Tests.

TEST RESULTS

MOST PROBABLE CAUSES

Drifting occurs in Tests No. 1 and No. 3

1. Leakage between piston and cylinder.

2. Leakage between ripper circuit valve spool and

body.

3. Leakage in restrictor valve.

NOTE: Remember that an O-ring seal failure in circuit will have same effect as a major component failure.

PRESSURE RELIEF VALVE TESTS

WARNING

Do NOT remove hydraulic tank filler cap or disconnect or remove any hydraulic system line or fitting

unless hydraulic system pressure has been relieved. Hydraulic system pressure can be over 2500 psi

(17,237 kPa), even with engine and pump OFF. To relieve pressure, lower all hydraulic attachments to

the ground and shut down engine. Move control levers through all operating positions, then SLOWLY

loosen hydraulic tank filler cap. After maintenance, tighten all connections before applying pressure.

Escaping hydraulic fluid under pressure can penetrate the skin, causing serious injury or death.

At operating temperature hydraulic oil is hot. Allow hydraulic oil to cool before disconnecting any

hydraulics. Failure to do so could result in injury.

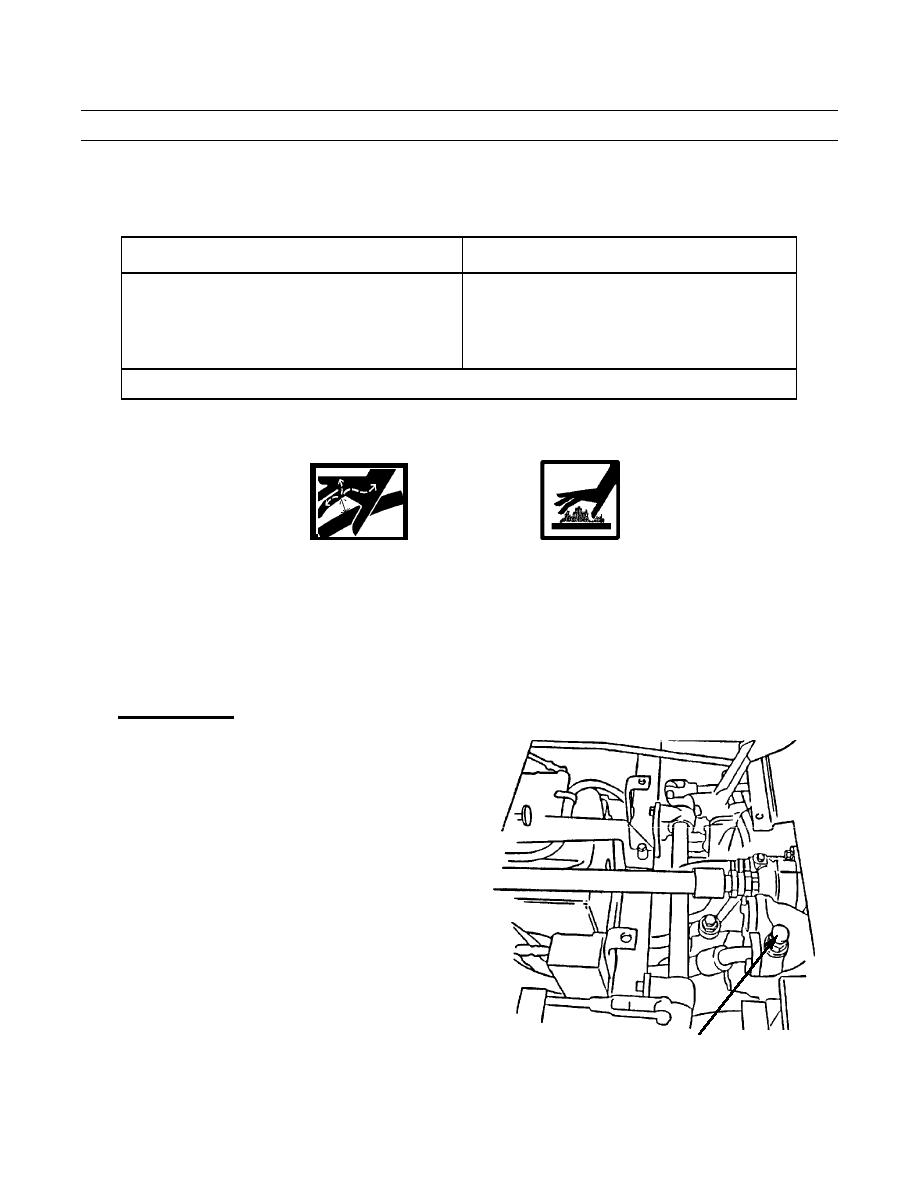

1.

Main Relief Valve.

a.

Operate machine until hydraulic system is at

operating temperature. Lower implements to the

ground and bulldozer blade level. Shut down

engine. Move all hydraulic control levers to all

positions to relieve pressure in lines. Return all

control levers to HOLD position.

b.

Install a 0-4000 psi (0-27,579 kPa) gage in pres-

sure tap (1) of main hydraulic pump.

1

387-784

0227 00-6

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |