|

|||

|

|

|||

|

Page Title:

HYDRAULIC SYSTEM TEST PROCEDURES - CONTINUED |

|

||

| ||||||||||

|

|

TM 5-2410-237-23

HYDRAULIC SYSTEM TESTS - CONTINUED

0227 00

HYDRAULIC SYSTEM TEST PROCEDURES - CONTINUED

Blade Tilt Circuit Drift Tests. Refer to Table 4 for correct test results for the following checks. Refer to Table 5 to

3.

interpret test results.

a.

Test No. 1. Lower blade flat on ground. Raise front of tractor off ground by lowering right side of blade (tilt right).

Place tilt circuit in HOLD position. Shut off engine and measure tilt cylinder rod movement.

b.

Test No. 2. Lower blade flat on ground. Raise front of tractor off ground by lowering left side of blade (tilt left).

Place tilt circuit in HOLD position. Shut off engine and measure tilt cylinder rod movement.

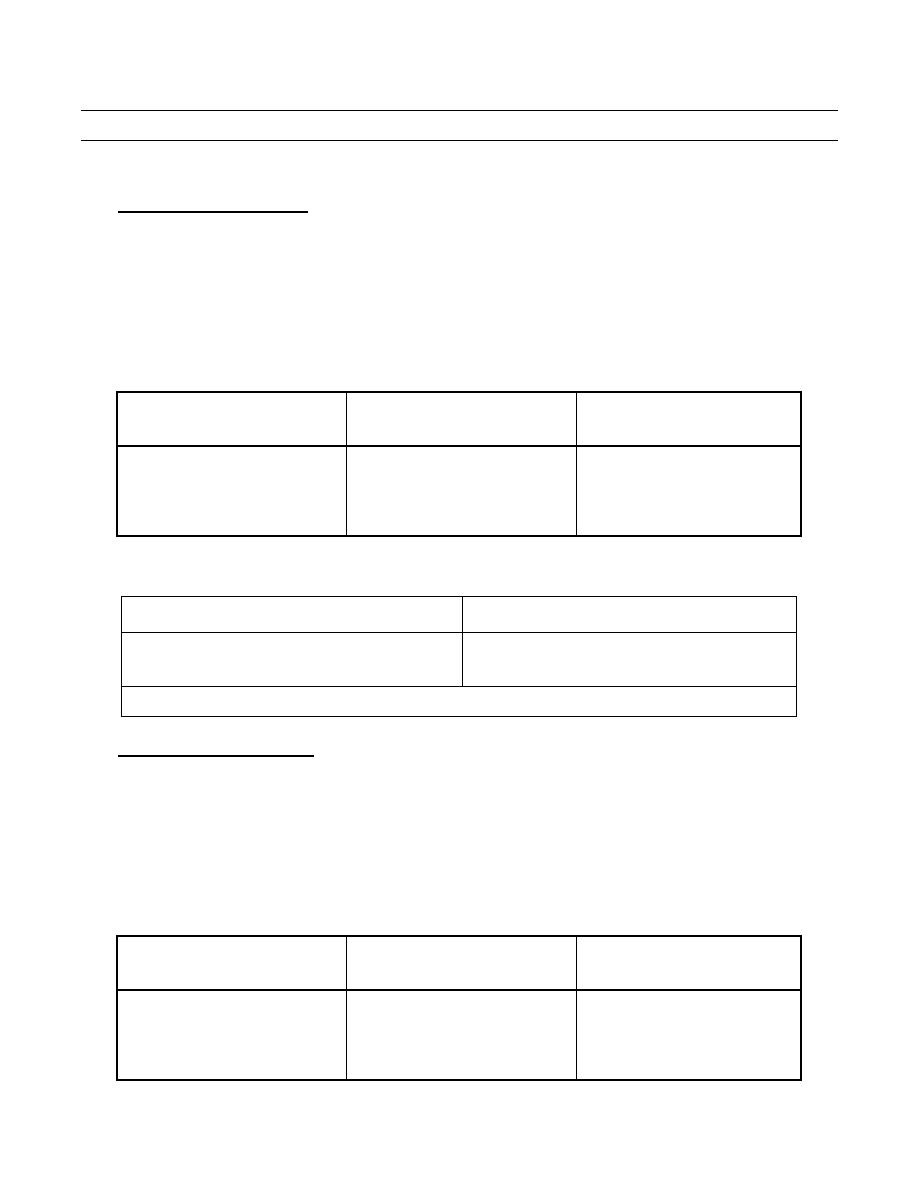

Table 4. Blade Tilt Circuit Drift Tests.

MAXIMUM CYLINDER

DURATION OF TEST

OIL TEMPERATURE

MOVEMENT

0.44 in. (11.2 mm)

5 min.

100F (38C)

0.44 in. (11.2 mm)

2.7 min.

135F (57C)

0.44 in. (11.2 mm)

1.7 min.

175F (79C)

Table 5. Interpretation of Blade Tilt Circuit Drift Tests.

TEST RESULTS

MOST PROBABLE CAUSES

Drifting occurs in Tests No. 1 and No. 2

1. Leakage between piston and cylinder.

2. Leakage between tilt circuit valve spool and body.

NOTE: Remember that an O-ring seal failure in circuit will have same effect as a major component failure.

4.

Ripper Lift Circuit Drift Tests. Refer to Table 6 for correct results for the following checks. Refer to Table 7 to inter-

pret test results.

a.

Test No. 1. Raise rear of tractor off ground by lowering ripper. Place ripper control lever in HOLD position. Shut

off engine and measure ripper cylinder rod movement.

b.

Test No. 2. Raise ripper off ground. Place ripper control lever in HOLD position. Shut off engine and measure rip-

per cylinder rod movement.

Table 6. Ripper Lift Circuit Drift Tests.

MAXIMUM CYLINDER

DURATION OF TEST

OIL TEMPERATURE

MOVEMENT

0.38 in. (9.7 mm)

5 min.

100F (38C)

0.38 in. (9.7 mm)

2.7 min.

135F (57C)

0.38 in. (9.7 mm)

1.7 min.

175F (79C)

0227 00-5

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |