|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 5-2410-237-23

STEERING BRAKE HYDRAULIC CONTROL ASSEMBLY MAINTENANCE - CONTINUED

0151 00

DISASSEMBLY - CONTINUED

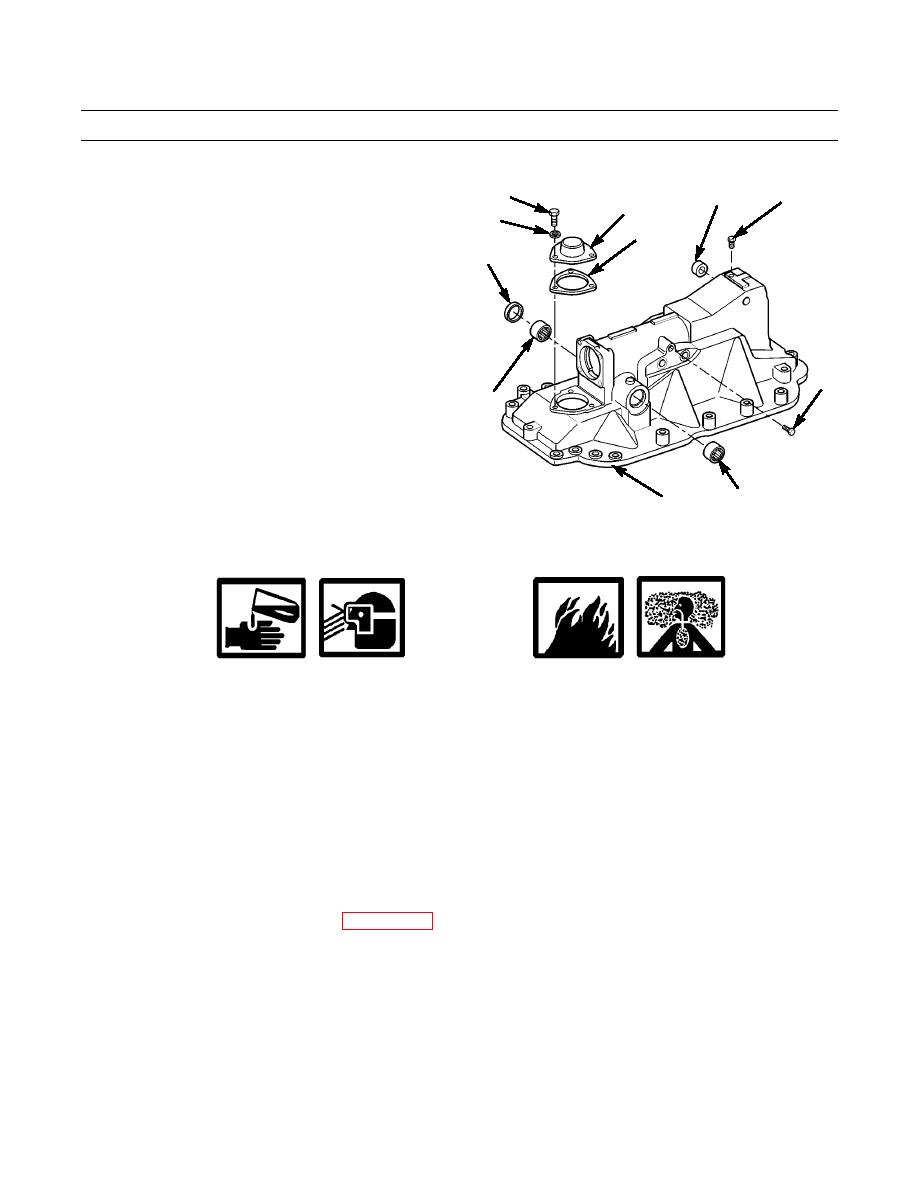

24.

Remove seal (95) and two bearings (96) from shaft

98

97

102

100

mounting holes in hydraulic control (12). Discard seal.

99

101

25.

Turn hydraulic control (12) to open side down.

95

26.

Remove seal (97) from parking brake lever assembly

hole in hydraulic control (12). Discard seal.

27.

Remove three capscrews (98), lockwashers (99), cover

(100) and gasket (101) from end of hydraulic control

(12). Discard lockwashers and gasket.

28.

Remove plug (102) from top of hydraulic control (12).

103

29.

Remove plug (103) from side of hydraulic control

96

(12).

387-715

96

12

CLEANING

WARNING

Solvent cleaning compound MIL-PRF-680 Type III is an environmentally compliant and low toxic

material. However, it may be irritating to the eyes and skin. Use protective gloves and goggles. Use in

well-ventilated areas. Keep away from open flames and other sources of ignition.

Particles blown by compressed air are hazardous. DO NOT exceed 15 psi (103 kPa) nozzle pressure

when drying parts with compressed air. Use a maximum of 30 psi (207 kPa) when cleaning compo-

nents. DO NOT direct compressed air against human skin. Failure to follow this warning may result in

serious injury or death. Make sure air stream is directed away from user and other personnel in the

area. To prevent injury, user must wear protective goggles or face shield.

1.

Clean all removed components with solvent cleaning compound.

2.

Thoroughly dry components with compressed air or clean rags.

3.

Remove all old gasket material from mounting flange of hydraulic control and mounting surface on top of gear case.

INSPECTION

1.

Inspect all removed components IAW (WP 0241 00).

2.

Replace any component found to be damaged.

0151 00-10

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |