|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

7-6. Recoil Springs

d. Front Idler Adjustment.

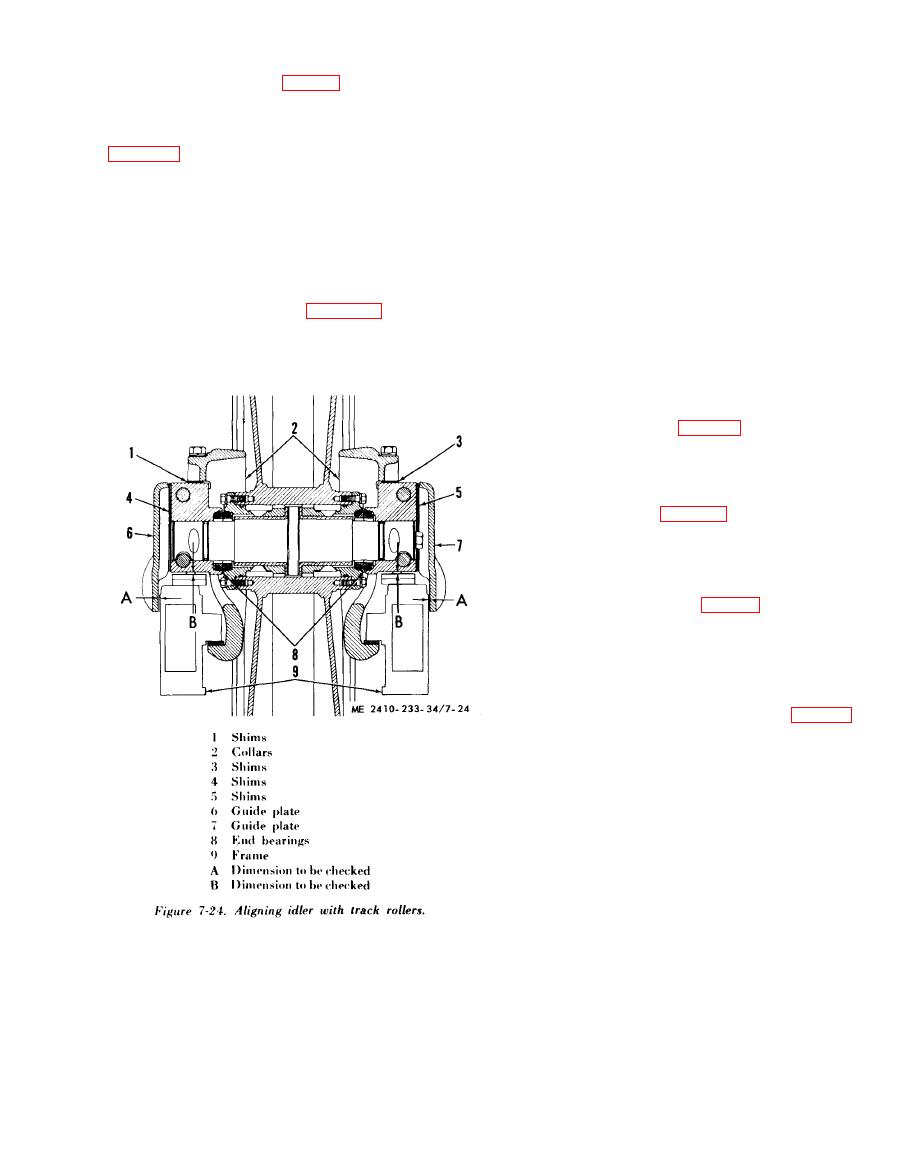

(1) Install shims (1, fig. 7-24) and (3) between

a. Removal.

collars (2) and bearings (8) to align the idler with

WARNING

the track rollers and keep clearance (B) between

Be certain the hydraulic pressure in the

the yoke and the plate with tolerances given in

t r a c k adjusting mechanism is com-

pletely relieved and the cylinder can be

NOTE

r e m o v e d to the rear into the recoil

Removing shims (1) or (3) from one end bearing will

spring front pilot before attempting to

tilt the top of the idler away from that bearing. Adding

separate the track or remove the track

shims to one end bearing will tilt the top of the idler

adjusting mechanism. On machines that

toward that end bearing.

have badly worn track, it is possible for

(2) Install enough shims (4) and (5) between

the hydraulic track adjuster to be ad-

bearings (8) and guide plates (6) and (7) to provide

justed forward to the limit of its travel

clearance (A) between guide plates (6) and (7) and

and t h e stop w i l l b e a g a i n s t the

the frame (9). Refer to table 1-5 for correct

equalizer bar support. The hydraulic

clearance.

cylinder could have high oil pressure in

(3) Shims (4) and (5) are used to shift tbe idler

it even though the track is loose enough

from side to side to align idler and track properly.

to remove the master pin without

relieving the hydraulic track adjusting

pressure.

(1) Remove guards (fig. 7-25). Install drawbar

pin or hardwood block between tbe sprocket and

the track, and back up the machine slightly to

com press the recoil spring. When all the tension is

rem oved from recoil spring stops, remove locking

bolt and washer (4, fig. 7-26) and screw recoil

spring bolt nut (1) tight against rear pilot (2).

Remove the drawbar pin or hardwood block.

(2) Separate the track and lay it out flat (par 7-

1).

(3) Move cylinder (5, fig. 7-27) to the rear as

far as possible, into front pilot (2), separating tbe

cylinder from idler recoil rod ( 4). Move the idler

rod to the front as far as possible.

(4) Attach a hoist to and remove the recoil

spring assembly.

(5) Inspect antiextrusion ring (2, fig. 7-31)

and seal (1).

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |