|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

(2) Remove the clamping bolt and

lock

securing bearing cage holder assembly (2) to

outer

bearing adjustment nut (1).

(3) Using a puller and a step plate,

force

holder assembly (2) from taper on sprocket

shaft

(5).

NOTE

It may be necessary to strike the holder assembly with

a soft hammer to free it from taper on the shaft.

(4) Attach a hoist to support holder assembly

(2). Remove retaining nut (3), and the holder

assembly. Remove adjusting nut (1), metal floating

ring seal (9), holder assembly (2), and gasket (10),

bearing cage (7), and bearing cup (6) as a unit.

(5) Inspect the mating surfaces of metal

floating ring seals (8, and 9, fig. 6-114) for damage

or excessive wear (para 6-22).

(6) Align keyway (5) in the holder assembly

hub with the key on the sprocket shaft (6) and

install the unit in reverse order of removal.

NOTE

The bearing preload adjustment, for the hub support

bearings, is not made until the track roller frame outer

bearing has been installed. To set the bearing preload,

refer to paragraph 6-28.

b. Disassembly.

(1) Remove the dust guard.

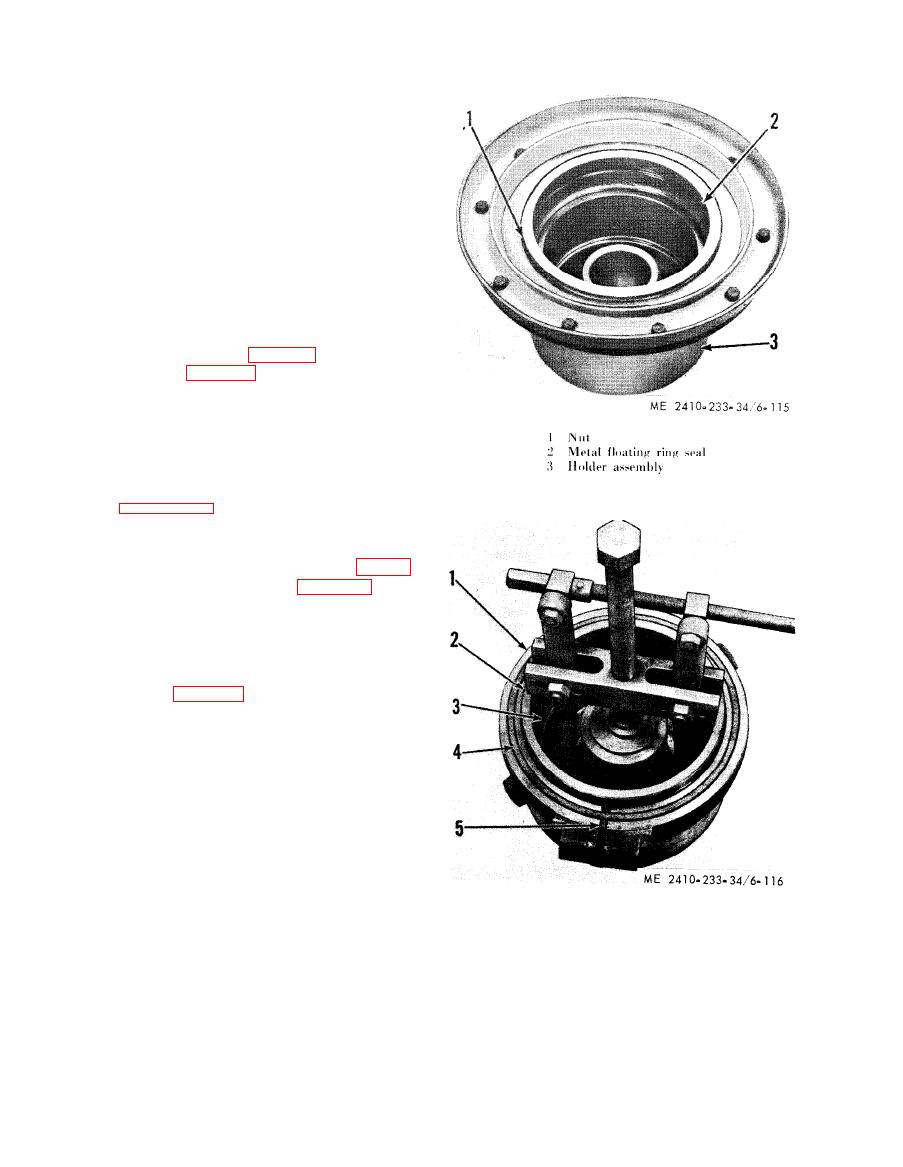

(2) Remove metal floating ring seal (2, fig. 6-

115), if replacement is necessary (para 6-22).

(3) Remove outer bearing adjusting nut (1)

from bearing cage holder assembly (3).

(4) Using a bearing cup pulling attachment, a

forcing bolt, a suitable spacer to cover the hole in

the holder assembly hub, and a step plate, pull

bearing cage (2, fig. 6-116) and cup (3) as a unit.

(5) Remove bearing cage holder gasket (4)

and seal (5) if replacement is necessary.

(6) Using a puller, an adapter and a bearing

cup pulling attachment, remove the cup (3) from

the bearing cage.

1

Holder assembly

2

Cage

3

Cup

4

Gasket

5

Seal

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |