|

|||

|

|

|||

|

Page Title:

Aligning Track Roller Frame With Sprocket |

|

||

| ||||||||||

|

|

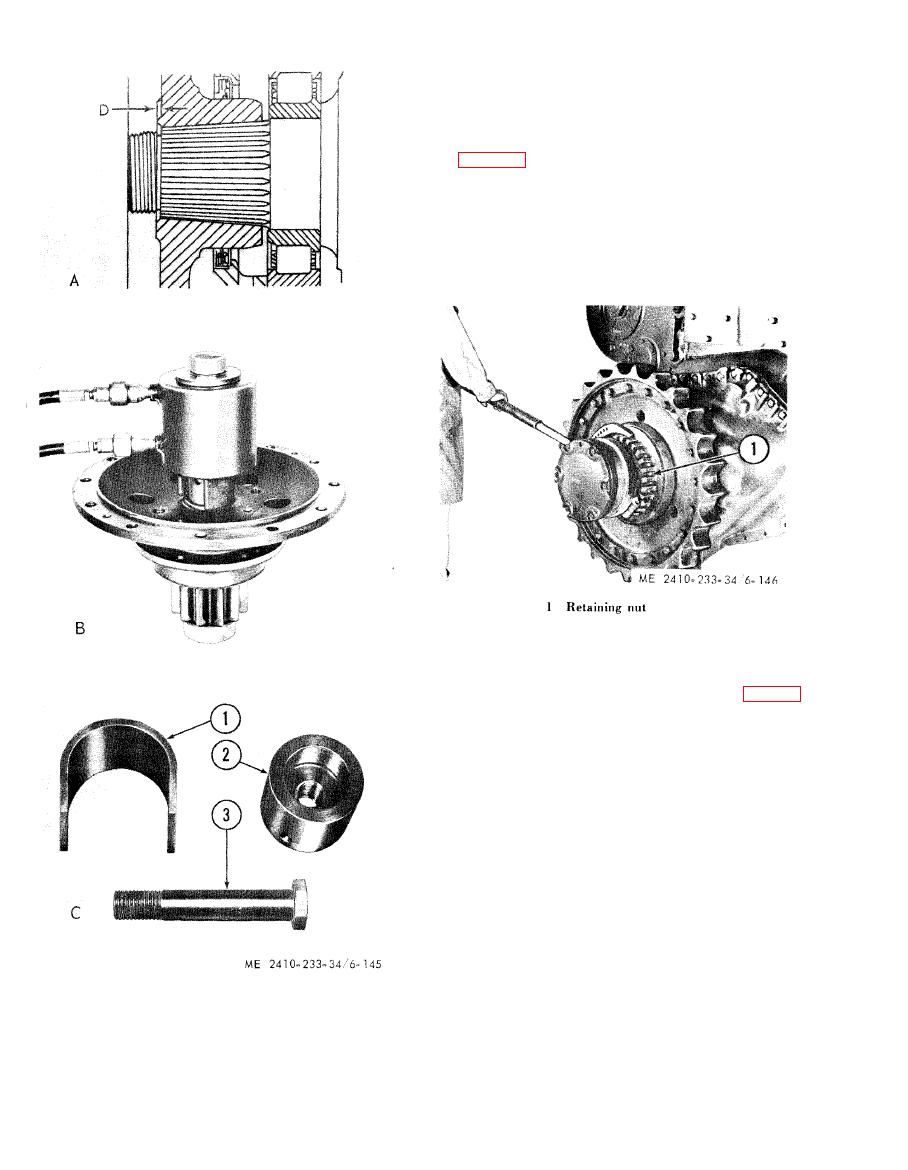

6-28. Final Drive Bearing Adjustments

a. After the final drive has been assembled and

the track roller frame outer bearing installed and

aligned, adjust the bearing preload on the sprocket

support bearings. With the adjusting nut lock and

clamping bolt removed, tighten the adjusting nut

(1, fig. 6-146) in a counterclockwise direction to the

torque value of 1200-1500 lb-ft.

b. Continue to tighten the nut until the lock can

be installed in one of the recesses in the retaining

nut.

c. Insert the clamping bolt and tighten to lock the

retaining nut in position.

6-29. Aligning T r a c k Roller Frame With

Sprocket

147) the center of the track rollers should be

centered with final drive sprocket (8), so the track

will lead straight off of rear roller (5) onto the final

drive sprocket and not rub against either the sides

of the sprocket or the rims of the track roller.

b. Final drive sprocket (8) should be centered in

the recess of rear track roller (5) so clearances (10)

and (12) between the outer face of the sprocket and

the inner edge of the track roller are equal.

c. When this properly adjusted, diagonal brace

(13) should be checked to see there is some

clearance at (14) and (15) in the recess in steering

clutch case (16).

d. To make this adjustment remove cap (1) from

outer bearing assembly (4) and remove lockring

(7), nut (2) and retainer assembly (9).

e. Add shims (3) between retainer assembly (9)

1 Sleeve

and holder assembly (11) to move the track roller

2 Adapter

3 Bolt

frame out, decreasing clearance (12) at the roller

D Dimension to be checked 0.094 in.-0.154 in.

and at diagonal brace (13) and increasing clearance

at (10) and (15).

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |