|

|||

|

|

|||

|

Page Title:

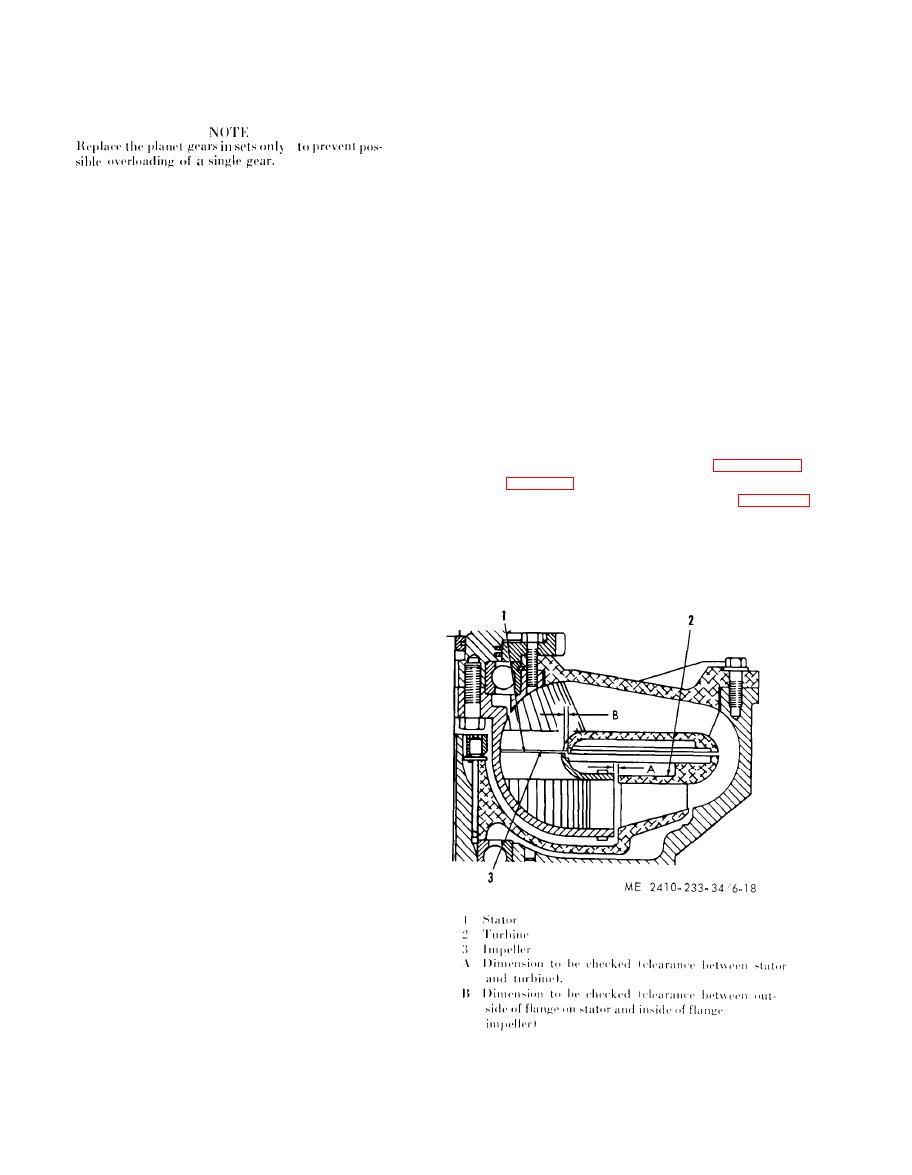

Figure 6-18. Torque converter clearances. |

|

||

| ||||||||||

|

|

pitted, cracked, broken, o r excessively worn teeth.

(q) Inspect the flange ring seals for damage

a n d wear. Replace damaged, worn, or questionable

Inspect the bearing surface for scoring, pitting, and

ring seals. Inspect the flange inner sleeve bearings

w e a r . Replace damaged or excessively worn gears.

for scoring. damage, and wear. The desired shaft to

bearing c l e a r a n c e i s 0 . 0 0 2 t o 0 . 0 0 5 i n c h . T h e

,

m a x i m u m a l l o w a b l e c l e a r a n c e is

0.015

inch.

Replace scored,

damaged,

or

excessively

worn

(c) I n s p e c t t h e n o n - m e t a l l i c w a s h e r s f o r

s l e e v e bearings.

d a m a g e a n d w e a r . T h e washer thickness (new) is

(r) I n s p e c t a l l g e a r s f o r c h i p p e d , p i t t e d ,

0.073 0.002 inch. Replace damaged or worn

broken, or excessively worn teeth. Replace

washers. Minimum allowable thickness is 0.065

excessively - w o r n g e a r s .

defective

or

inch.

(d) I n s p e c t t h e p l a n e t c a r r i e r f o r c r a c k s ,

h o u s i n g s for cracks, breaks, and wear. Repair or

b r e a k s , and distortion. Replace a defective carrier.

r e p l a c e as dictated by the extent of damage.

(e) I n s p e c t t h e c a r r i e r t h r u s t w a s h e r s f o r

(3) C h e c k i n g t o r q u e c o n v e r t e r c l e a r a n c e . T o

damage and wear. Replace the thrust washer if

m a i n t a i n efficiency of the torque converter, it is

damaged or if considerable wear is indicated.

n e c e s s a r y t h a t m a x i m u m wear

limits

between

(f) Inspect the planet sun gear for chipped,

certain components be observed and used as a

pitted, broken, or worn teeth. Replace the sun gear

g u i d e when determining parts replacement. At the

if damaged or worn excessively.

t i m e of reassembly, use the procedure listed below

(g) Inspect the sun gear positioning springs

to check the clearance. The measured distances are

f o r breaks or damaged condition. Replace defective

total diametral clearances which are twice the

springs.

a c t u a l running clearances (A) and (B), figure 6-18.

(h) I n s p e c t t h e p i l o t b e a r i n g f o r s c o r i n g .

R e f e r to table 1-4 for correct diametral clearances.

p i t t i n g , and wear. Replace a scored, pitted, rough,

o r cxcessively worn bearing.

19,

between blade ends in turbine flange, as

(i) R e p l a c e t h e o u t p u t shaft rear seal.

illustrated.

Install the seal with the lip facing the torque

divider.

(b) Position stator (1) in turbine (2) being

c a r e f u l not to move steel balls (4).

(j) I n s p e c t t h e o u t p u t s h a f t b e a r i n g s f o r

scoring, pitting, and wear. Replace defective

b e a r i n g s . Examine the shaft splines for distortion

and wear. Replace a defective shaft. Replace a

damaged or questionable ring seal.

(k) I n s p e c t t h e i m p e l l e r f o r

damage

and

w e a r . The desired impeller to stator clearance is

0.009 to 0.015 inch. The maximum allowable

clearance i s 0 . 0 2 3 i n c h . R e p l a c e a d a m a g e d o r

w o r n impeller.

(see

(3)

below

for

pleasuring

procedure).

(l) Inspect the stator for damage and wear.

R e p l a c e a (damaged or worn stator.

(m) Inspect the, carrier inner bearing for

scoring, pitting, and wear. R e p l a c e a scored, pitted,

rough, or excessively worn bearing. Examine the

c a r r i e r r i n g type s e a l s f o r d a m a g e a n d wear.

R e p l a c e worn, damaged, or questionable ring seals.

(n) Inspect the carrier bearing for scoring,

p i t t i n g , and wear. Replace a scored, pitted, rough,

o r excessively worn hearing.

(o) I n s p e c t t h e t u r b i n e f o r d a m a g e a n d

wear. The desired stator to turbine clearance is

0.012

to

0.018

inch.

The

maximum

allowable

c l e a r a n c e i s 0 . 0 3 0 i n c h . R e p l a c e a d a m a g e d or

w o r n turbine (See subpara (3) below for measuring

procedure).

(p) Inspect the turbine bearing for scoring,

p i t t i n g , and wear. Replace a scored, pitted, rough,

o r excessively worn bearing.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |