|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

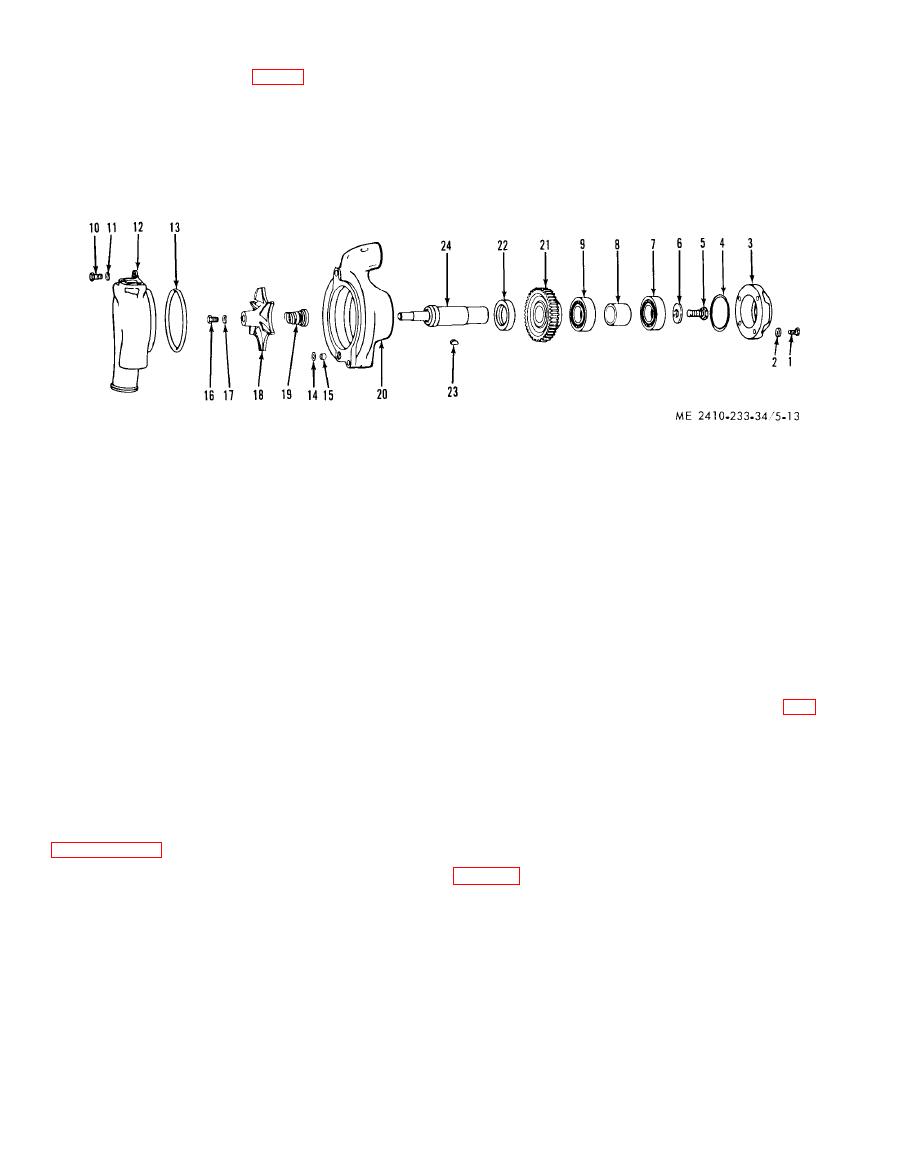

c. Disassembly.

hearing (7) from the impeller shaft. Remove the

(1) Remove the bolts ((1) fig. 5-13) and lock-

spacer (8) and hearing (9).

washers (2) and remove the cover (3) from the wa-

(4) Remove the bolts (10) and lockwashers

ter pump. Remove the seal (4).

(11). Remove the cover (12) from the body.

(2) Remove the bolt (5) and washer (6).

Remove the seal (13), seal (14), and dowel (15).

(3) Using a suitable puller, remove the

13

Seal

1

Bolt

14

Seal

2

Lockwasher

15

Dowel

3

Cover

16

Bolt

4

Seal

17

Washer

5

Bolt

18

Impeller

6

Washer

19

Spring

7

Bearing

20

Body

8

Spacer

21

Gear

9

Bearing

22

Seal

10

Bolt

23

Key

11

Lockwasher

24

Impeller shaft

12

Cover

reverse order of disassembly. Grease the seals

(5) Remove the bolt (16) and washer (17).

Remove the impeller (18) and spring (19) from the

before installing and use a seal installation tool to

insert the seals. Tighten the impeller bolt (16, fig.

impeller shaft.

(6) Remove the impeller shaft from the body

5-15) to a torque of 27 to 29 foot-pounds.

f. Installation. Reverse removal procedure and

(20).

install the water pump on the engine.

(7) Remove the gear (21), seal (22), and key

(23) from the impeller shaft (24).

5-7. Engine oil Cooler

c. Cleaning. Clean all components except

a. Removal.

bearings in P-D-680 cleaning solvent and dry with

(1) Drain cooling system (TM 5-2410-233-

compressed air. Clean bearings as instructed in

10).

(2) Loosen the water inlet bonnet hose clamps

d. Inspection and Repair.

(1) Check the housings for cracks at the

(3) Remove oil filters (TM 5-2410-233-20).

mounting flanges. Repair or replace as required.

(4) Remove the oil level gauge guide clamp

(2) Inspect the impeller for dents, nicks,

mounting bolt.

cracks, chips and bent or broken splines. Repair or

(5) Remove the oil cooler-to-elbow assembly

replace as necessary.

mounting bolts.

(3) Inspect the bearing for scoring, wear,

(6) Remove the two support bracket

scratches, pitting and other damage. Replace as

mounting bolts and remove the engine oil cooler

required.

and oil filter base as a unit.

(4) Replace all seals and gaskets.

(7) Separate the oil filter base from oil cooler.

e. Reassembly. Assemble the water pump in the

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |