|

|||

|

|

|||

|

Page Title:

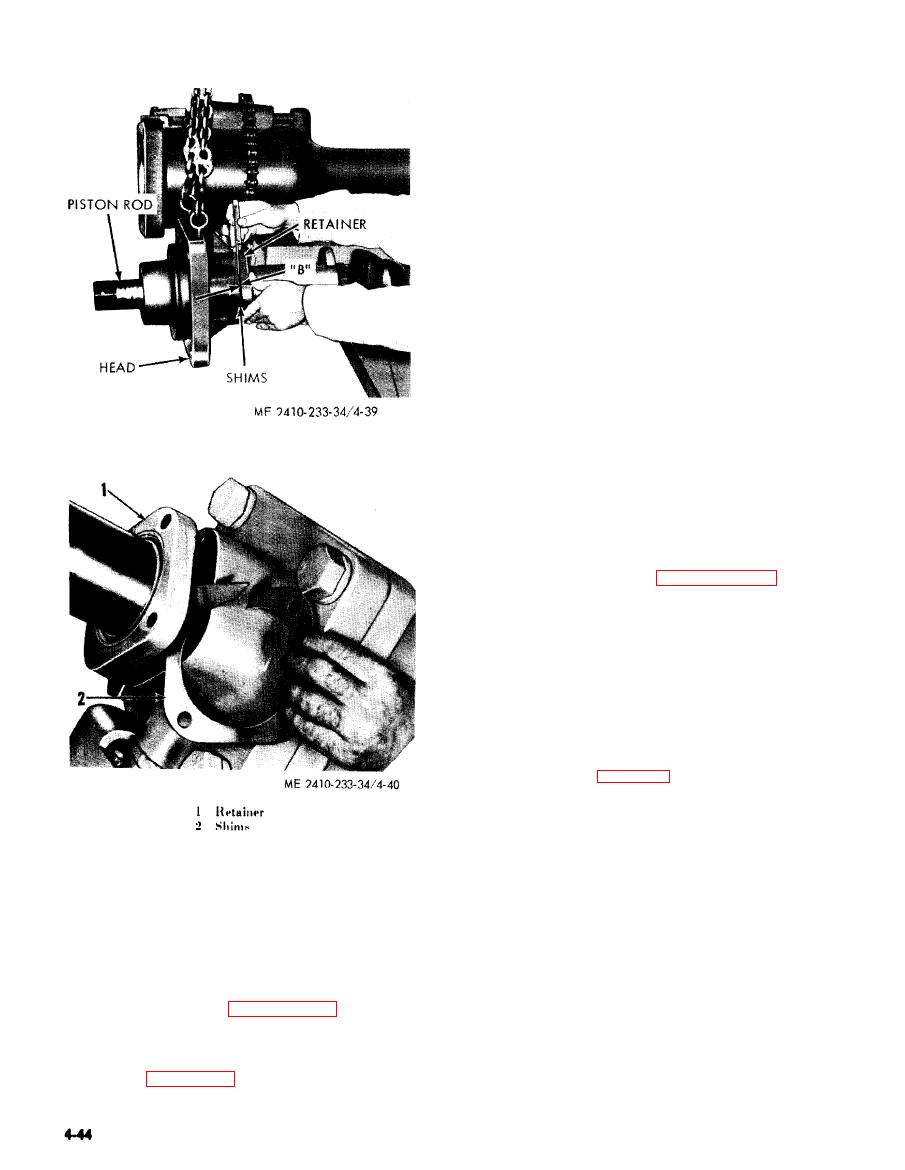

Figure 4-39. Measuring clearance. |

|

||

| ||||||||||

|

|

CAUTION

Extend the piston rod out of the

cylinder before removing bolts, to

p r e v e n t scoring of the cylinder walls

w h e n removing the piston from the

cylinder.

d. Cleaning. Clean all parts with cleaning

solvent (Fed. Spec. P-D-680). Dry parts with a lint-

free cloth.

e. Inspection and Repair.

(1) Inspect the cylinder for scoring, pitting,

and wear. Replace a cylinder which cannot be

made serviceable with light honing.

CAUTION

Do not weld on the cylinder assembly as

scoring may result from shrinkage.

(2) Replace all seals, packing, and wear rings.

(3) Inspect the rod end bearing for scoring,

damage, and wear.

(4) Inspect the piston rod for nicks, burrs,

pitting, distortion, and wear. Repair or replace a

damaged or distorted rod. Remove minor nicks and

burrs using a fine emery stone. Pitted, scored, or

worn rods may be repaired by metalizing or

chrome-plating and regrinding to original size. A

noncorrosive metal will be used to metalize shafts.

(5) Inspect remaining cylinder parts for wear

or damage. Replace all defective parts.

install the ripper "lift" cylinders on the ripper.

Key to figure 4-41.

1 Bearing

2 Rod

3 Seal

4 Bolt

5 Lockwasher

6 Retainer

h. Installation. Reverse removal procedure and

7 Shim

install the tilt cylinder on the bulldozer.

8 Shim

9 Packing

10 Screw

a. General. The ripper hydraulic lift cylinders

11 Lockwasher

are located on each side of the ripper and are used

12 Head

13 Packing

to raise and lower the ripper. Both cylinders are

14 Washer

removed and installed in a similar manner.

15 Seal assembly

16 Piston

the cylinders.

17 Ring

c. Disassembly. Disassemble t h e ripper lift

18 Nut

19 Fitting

cylinders according to sequence of index numbers

20 Cylinder assembly

assigned to figure 4-41.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |