|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 5-2410-233-23

WINCH ASSEMBLY REPLACEMENT - CONTINUED

0139 00

INSTALLATION - CONTINUED

WARNING

Use extreme caution when handling heavy parts. Provide adequate support and use assistance during pro-

cedure. Ensure that any lifting device used is in good condition and of suitable load capacity. Keep clear of

heavy parts supported only by lifting device. Failure to follow this warning may cause injury or death.

NOTE

Use a tap to chase and clean threaded holes in bosses to which chain end links are attached.

4.

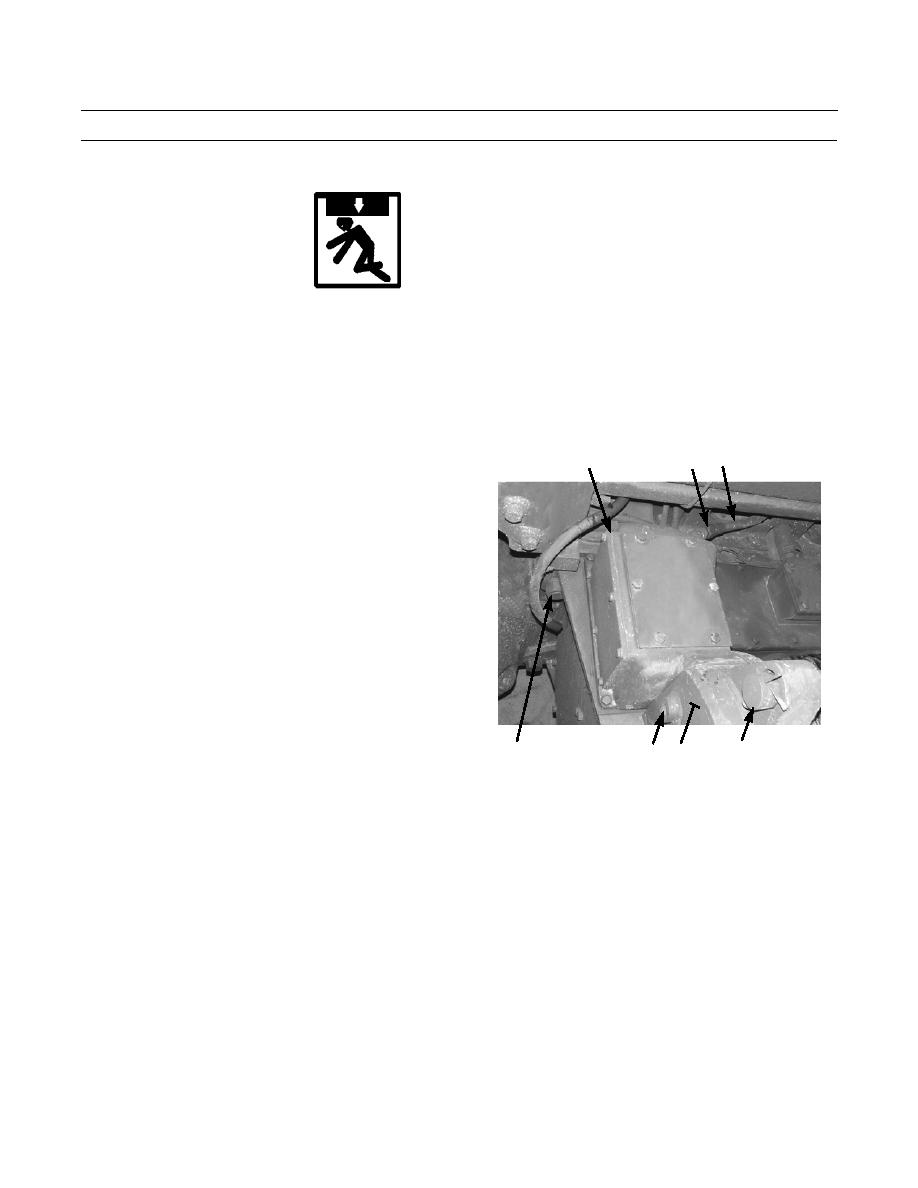

Attach two lifting links with 3/4 -10 x 1-1/2 in. bolts in

6

5

7

threaded boss (8) on each side of winch (9).

5.

Attach a suitable three-point lifting device to two lift-

ing links on each side of winch (9) and to bar (10).

CAUTION

Use caution when aligning drive shaft to drive

shaft opening at rear of tractor. Install winch

slowly and carefully. Failure to maintain con-

trol of winch while it is inserted could cause

damage to mounting studs, drive shaft and

transmission.

NOTE

Assistance is required to align winch

drive shaft with transmission cou-

386-046

pling and output shaft.

11,12,13,14

10

8

9

Adjust lifting device as needed until

correct alignment is achieved.

6.

Align winch drive shaft (14) with opening in back of tractor. Rotate winch drive shaft to ensure that splines of transmis-

sion coupling and output shaft line up.

NOTE

Winch is correctly aligned and installed when winch case is flush against rear of tractor.

7.

Slowly move winch (9) toward tractor until coupling (20) on drive shaft (14) is seated in transmission and winch is

mounted on studs (13).

8.

Install six washers (12) and nuts (11) on studs (13).

9.

Tighten four nuts (11) at four larger mounting studs to 1500 lb-ft (2034 Nm).

10.

Tighten two nuts (11) at two smaller studs (13) to 1000 lb-ft (1356 Nm).

11.

Remove lifting device and two lifting links from threaded boss (8) on each side of winch (9).

12.

Connect coupling (5) of winch pump pressure line (6) to valve housing (7).

0139 00-5

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |