|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 5-2410-233-23

TRACK IDLER REPLACEMENT - CONTINUED

0115 00

INSTALLATION

WARNING

Use extreme caution when handling heavy parts. Provide adequate support and use assistance during pro-

cedure. Ensure that any lifting device used is in good condition and of suitable load capacity. Keep clear of

heavy parts supported only by lifting device. Failure to follow this warning may cause injury or death.

NOTE

Idler weighs 500 lb (227 kg).

Apply antiseize compound to all capscrews before installation.

1.

Attach a nylon sling and a suitable lifting device to each side of idler (5). Lift idler into position on track roller frame

(20).

2.

Install two new lockwashers (13) and capscrews (12) through bearing (14) into yoke (15) on each side of idler (5).

NOTE

Minimum clearance must be 0.030-0.075 in. (0.76-1.91 mm) between yoke (15) and plate assembly (21). Add

or remove shim(s) (18) as necessary.

3.

Install shims (18), two new lockwashers (17) and capscrews (16) at top of collar (19) and bearing (14) on each side of

idler (5).

4.

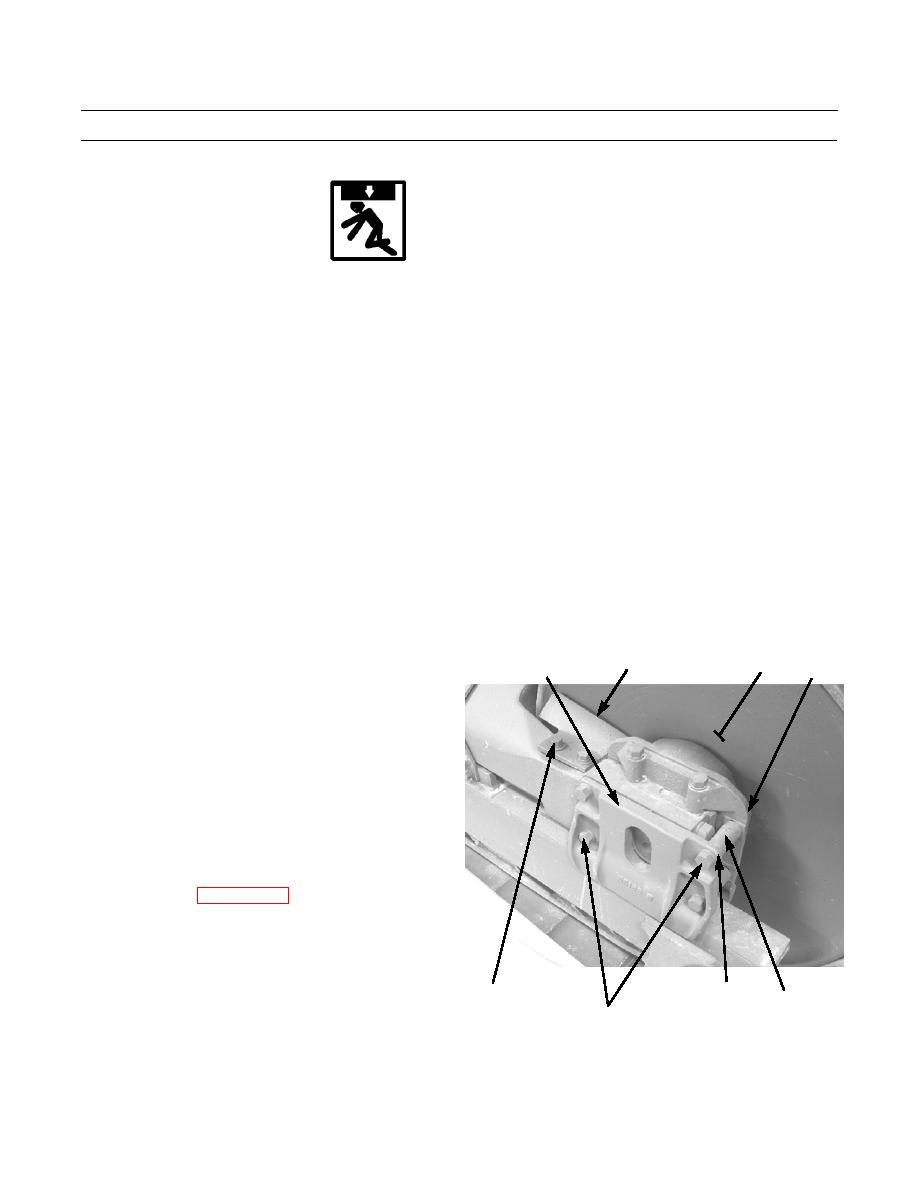

Install plate (11), two spacers (8), four new lockwashers (7), capscrews (6) and two strips (10) to each side of idler (5).

Leave capscrews loose for shimming.

NOTE

10

4

5

11

(HIDDEN)

Add or remove shims (9) as needed to provide a

clearance of 0.030 in. +/- 0.020 in. (0.76 mm +/-

0.51 mm) between plate (11) and track roller

frame (20).

5.

Remove two capscrews (6) and lockwashers (7) and

install shims (9) between plate (11) and spacers (8) on

each side of idler (5).

6.

Reinstall capscrews (6) and lockwashers (7). Tighten

capscrews to 200 lb-ft (271 Nm).

7.

Install guard (4) with two capscrews (1), new lock-

washers (3) and washers (2) on each side of idler (5).

8.

Connect track (WP 0119 00).

9.

Test drive and check track for proper operation (TM 5-

2410-233-10).

386-215

9

1,2,3

8

(HIDDEN)

6,7

END OF WORK PACKAGE

0115 00-3

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |