|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 5-2410-233-23

TROUBLESHOOTING PROCEDURES - CONTINUED

0006 00

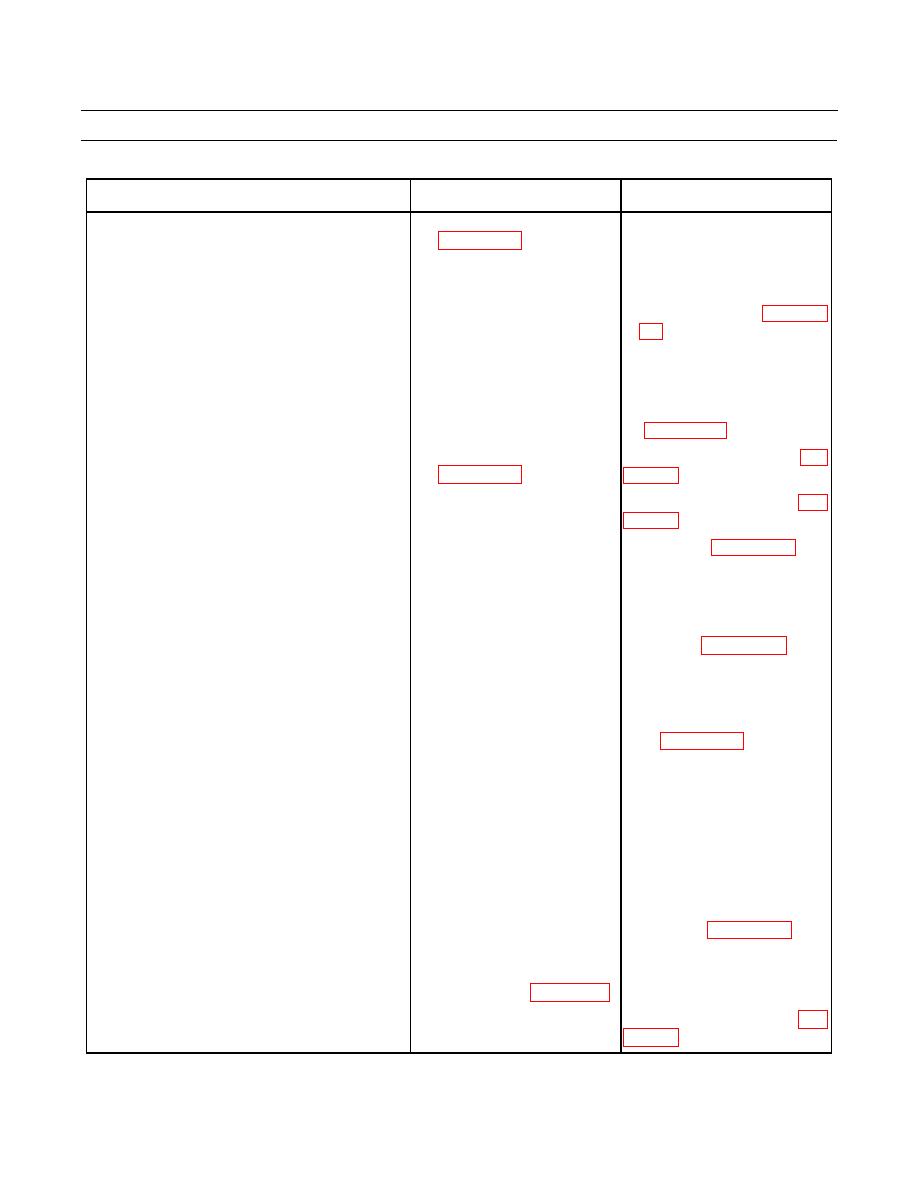

Table 1. Engine Troubleshooting Procedures - Continued.

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

3. Perform cylinder cutout test 1. If fuel pressure at suspect

10. Engine Knocks (Fuel Knock) - Continued.

cylinder fuel injection nozzle

appears to be equal to pressure

at all other fuel injection

nozzles, replace fuel injection

pump as necessary (WP 0051

2. If pressures are not equal,

remove blockage from nozzle-

to-pump fuel line or replace

nozzle for suspect cylinder

4. Check fuel injection timing Adjust timing, if necessary (WP

Mechanical Engine has internal damage.

Replace engine assembly (WP

11. Engine

Knocks

(Excessive

Noise).

12. Excessive Noise From Valve Mechanism 1. Check valve clearance.

Adjust valves (WP 0017 00).

(Clicking Sound).

2. Inspect valve mechanism. 1. Replace damaged compo-

Check valve springs and

nents.

locks. Damaged or worn locks 2. Replace

cylinder

head

can cause valve to fall into

assembly (WP 0023 00).

cylinder, resulting in serious

engine damage.

1. Check engine oil level for If dipstick indicates excessive oil,

13. Excessive Oil Consumption.

over filling.

drain crankcase to safe operating

level (WP 0010 00).

2. Check for external oil leaks.

a. Clean edges of rocker arm If leak (s) are found, tighten nuts,

cover, oil pan, oil filter, screws, lines and fittings and oil

turbocharger, engine oil filter.

cooler and other external

engine surfaces. Start

engine and check for leaks.

b. Check for oil leakage at If leakage is found, replace

inlet turbocharger (WP 0046 00).

turbocharger

to

manifold connection.

3. Check for a plug in each end Replace rocker shaft if missing.

of rocker shaft (WP 0017 00).

4. Engine has internal damage.

Replace engine assembly (WP

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |