|

|||

|

|

|||

|

Page Title:

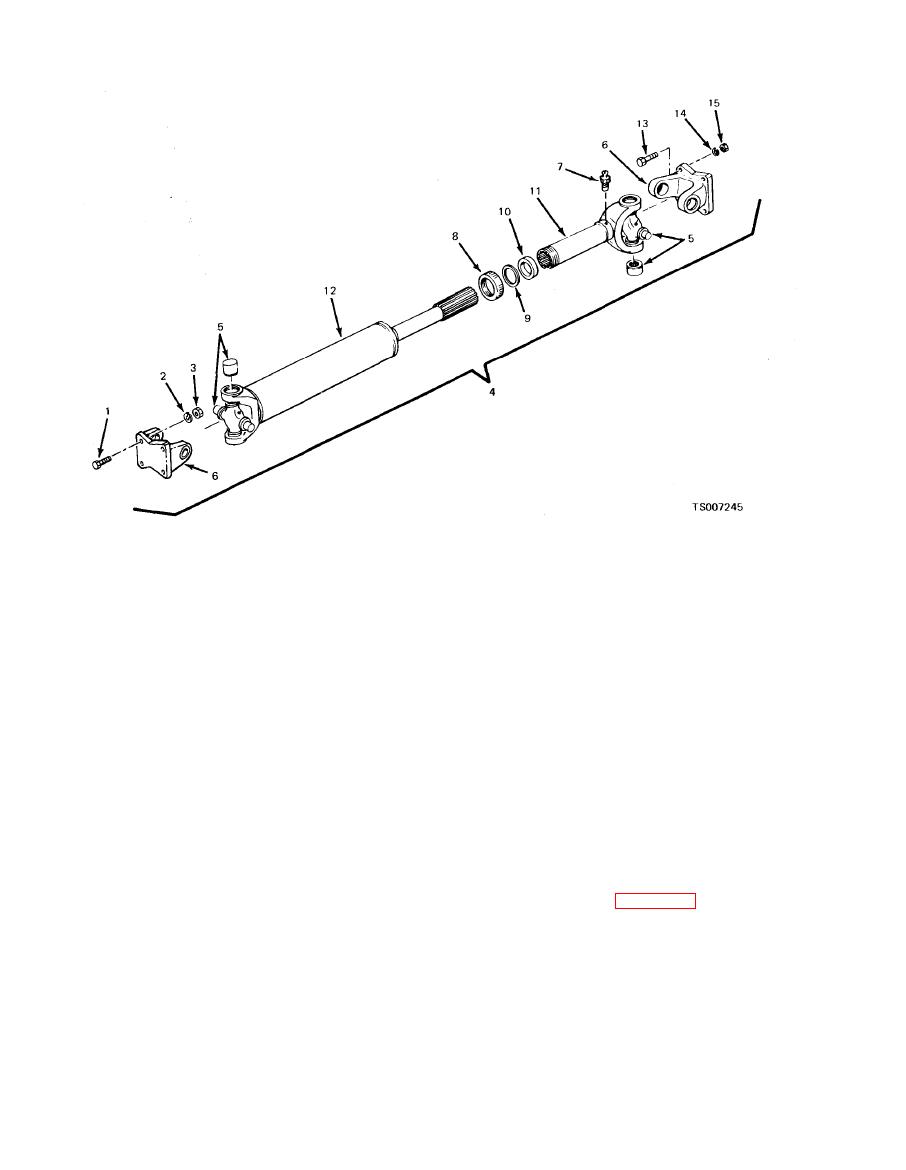

Figure 8-1. Propeller Shaft Assembly. |

|

||

| ||||||||||

|

|

TM 10-3930-633-34

1.

Screw

6. Flange yoke

11.

Sleeve yoke

2.

Lockwasher

7. Lubrication fitting

12.

Stub yoke

3.

Nut

8. Dust cap

13.

Screw

4.

Shaft assembly

9. Steel washer

14.

Lockwasher

5.

Cross and bearings

10. Cork washer

15.

Nut

(1) Remove snap rings by pinching the ends

(2) Do not disassemble the needle bearings.

together with a pair of needle nose pliers. If a ring

Clean with short stiff brush and blow out with

c o m p r e s s e d air. Work a small quantity of

does not readily free from the groove, tap the end

lubricant (140 S. A. E. oil) into each bearing cap

of the bearing cap lightly to relieve the pressure

and turn the needle bearing on the trunnion to

against the ring.

check wear. Replace if worn.

(2) Remove needle bearings (5) by driving on

(3) Because worn needle bearings used with a

the end of one bearing cap until the opposite

journal cross or new needle bearings used with a

bearing cap is forced out of the yoke. Turn the

worn journal cross will wear more rapidly, making

joint over and tap on the end of the journal cross

another replacement necessary in a short time,

until the opposite bearing cap is free. Use a

always replace the journal cross and four needle

wooden dowel, of a diameter about 1/32 to 1/16

bearing caps as a unit. These parts are furnished

smaller than the hole in the yoke, as a drift.

together in the service assembly. (See TM 10-

(3) Separate journal cross and yokes by

3930-633-34P).

sliding journal to the side of the yoke, and tilting

over the top of the yoke lug.

the propeller shaft as follows:

(4) Free slip yoke (11) and stub yoke (12) by

unscrewing dust cap (8) and pulling apart.

(1) Lubricate the splines on the stub shaft

with clean engine oil (OE) and place dust cap (8),

b. Cleaning, Inspection, and Repair.

(1) Clean all parts in a bath of solvent,

steel washer (9) and cork washer (10) over the

Federal Specification P-D-680. Allow the parts to

stub spline (11).

remain in the solvent for some time to loosen up

(2) Slide stub yoke (12) into slip yoke (11),

any particles of grease or foreign matter, Remove

being very careful to make certain the arrows

stamped on the slip yoke and stub yoke are

any burrs or rough spots from any machined

surf aces.

exactly in line. Tighten dust cap on slip yoke.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |