|

|||

|

|

|||

|

Page Title:

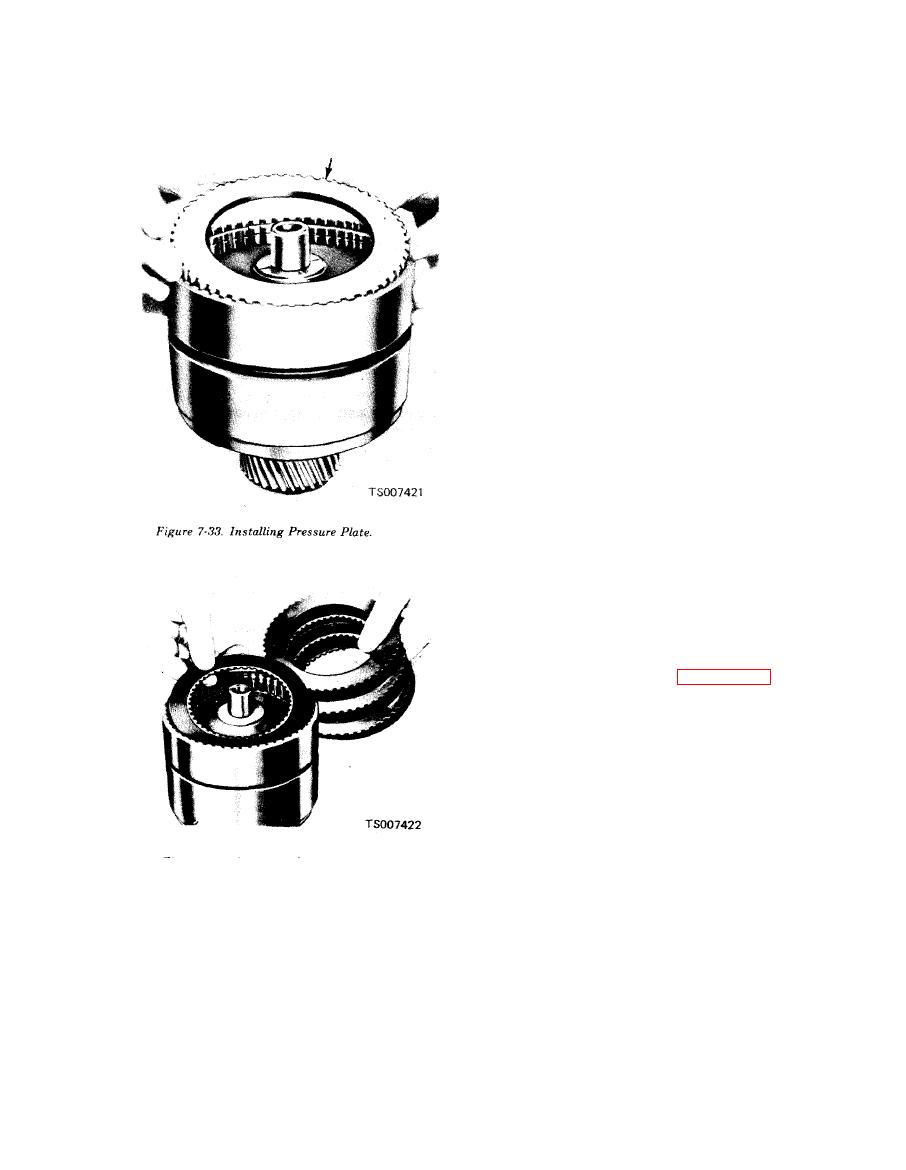

Figure 7-34. Installing Clutch Plates. |

|

||

| ||||||||||

|

|

TM 10-3930-633-34

(7) The final friction plate to be installed is

selective. Install the thickest plate that will be a

minimum of 0.010 inch below input shaft shoulder

in cylinder. For all other plates, use the thinnest

available. Refer to TM 10-3930-633-34P for

available plate thicknesses.

(8) Install the turbine shaft in the clutch

cylinder, and then install the snap ring. Make

sure the snap ring is fully seated in the groove.

(9) Install the thrust washer on the turbine

shaft.

Prior to reassembly of the transmission, check

for damage to the case and other parts as outlined

below:

a. Case.

(1) Inspect the case for cracks and stripped

threads. Inspect the gasket surfaces and mating

s u r f a c e s for burrs. Check the vent for ob-

structions, and check all fluid passages for ob-

structions and leakage.

(2) Inspect the case bushing for scores.

Check all parking linkage parts for wear or

damage.

(3) Use helicoil inserts to repair damaged

threads.

b. Primary Sun Gear Shaft.

(1) Inspect the primary sun gear for broken

or worn teeth. Inspect all thrust surfaces and

journals for scores. Check all fluid passages for

obstructions and leakage. Inspect the seal ring

grooves for burrs. Refer to figure 7-35.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |