|

|||

|

|

|||

|

Page Title:

Section Vlll. CAMSHAFT AND TIMING GEARS |

|

||

| ||||||||||

|

|

TM 10-3930-633-34

(6) Install the washer and capscrew. Torque

(4) Lubricate the crankshaft with a white

the cap screw to specifications.

lead and oil mixture to facilitate installation and

(7) Apply oil-resistant sealer to the cavities

removal of the damper. Lubricate the front oil

seal rubbing surface on the damper inner hub and

between the rear main bearing cap and cylinder

the inner surface (sealing area) of the oil seal with

block (fig. 6-42). Install a new oil pan rear seal in

Lubriplate or equivalent.

the rear main bearing cap and apply a bead of oil-

(5) Align the damper keyway with the key

resistant sealer to the tapered ends of the seal.

(8) Install new side gaskets on the oil pan

on the crankshaft. Install the damper on the

crankshaft as shown in figure 6-48.

with oil-resistant sealer (fig. 6-42 ). Position a new

cylinder front cover seal on the oil pan.

(9) Clean and install the oil pump screen and

inlet tube assembly. Install the oil pan and

related parts following the procedure under Oil

Pan Installation. Install the oil level dipstick.

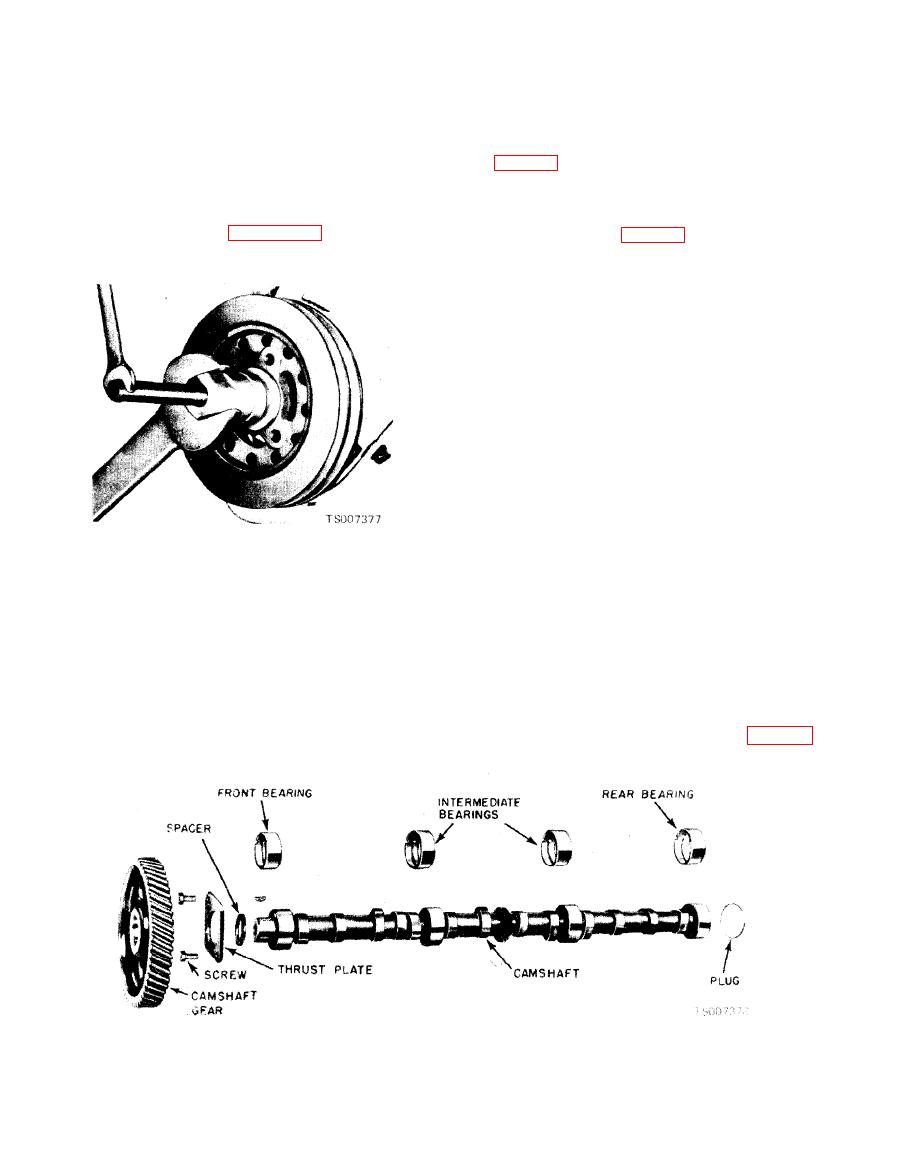

Section Vlll. CAMSHAFT AND TIMING GEARS

located between the camshaft gear and the front

6-37. General

journal on the camshaft. An eccentric, made

The camshaft is supported by four bearings,

integral with the camshaft, operates the fuel

pressed into the cylinder block. The camshaft is

pump. A gear is cast integrally with the camshaft

driven by a timing gear, pressed onto the cam-

to drive the distributor and the oil pump. The

shaft, in mesh with a gear on the crankshaft.

camshaft and related parts are shown in figure 6-

Camshaft thrust is controlled bv a thrust plate

49.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |