|

|||

|

|

|||

|

Page Title:

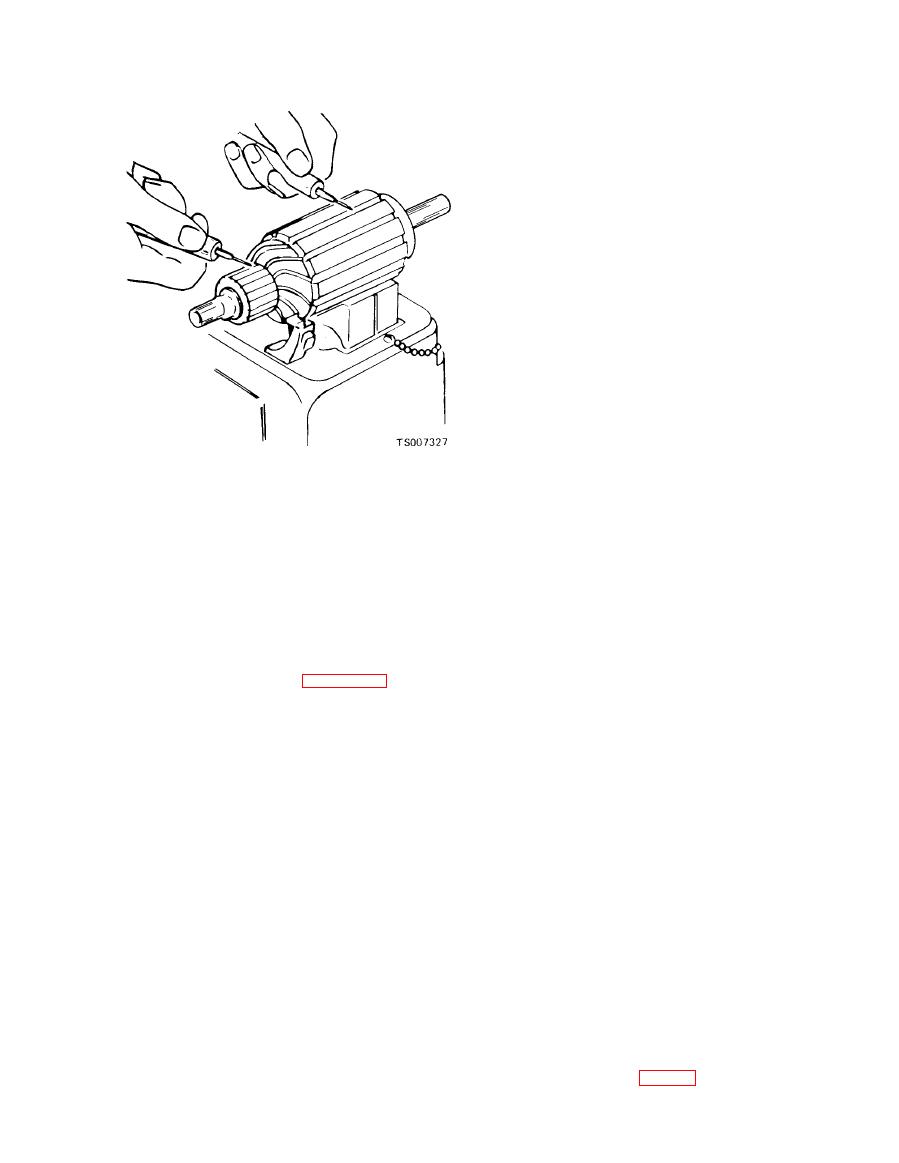

Figure 3-7. Testing for Grounds. |

|

||

| ||||||||||

|

|

TM 10-3930-633-34

(4) To force the retainer over the snap ring,

place a suitable washer over the shaft and squeeze

the retainer and washer together with pliers.

(5) Remove the washer.

(6) Lubricate bearing of drive housing (24)

with silicon grease and install armature and drive

assembly in housing.

CAUTION

Do not lubricate solenoid plunger or

solenoid cylinder.

(7) Install return spring (7) on solenoid

plunger (8) and insert plunger into solenoid

cylinder. Apply sealing compound on both sides

of solenoid flange where it extends between drive

housing and field frame. Attach plunger to shift

lever (13) with fulcrum pin (14). Fasten solenoid

to drive housing with two mounting screws (6).

(8) If field coils were removed from field

frame, position coils of replacement field coil

assembly (28) on pole shoes and mount each pole

shoe (27) in field frame with a pole shoe screw

(26). Use care in tightening screws to avoid

distortion of parts. Be certain that screws are

(7) Check field coils with a 12-volt test lamp

securely tightened. Insert ends of field coil leads

as outlined in steps 8 and 9.

through rubber grommet in field frame.

(8) With the field coil ground disconnected,

(9) Position field frame assembly over ar-

position one test prod on the field frame and the

mature assembly so that its down pin (17)

other to the field connector. If the lamp lights, the

engages the hole in drive housing. Use care to

field coils are grounded and must either be

prevent damage to brushes and brush holders.

replaced or repaired.

Make sure that brushes (31) are properly seated

(9) If the test lamp does not light when the

on commutator.

prods are connected to the ends of coil leads, the

(10) Install leather thrust washer (23) on

field coils are open.

commutator end of armature assembly. Lubricate

bearing in commutator end frame with silicon

(1) Place the drive pinion assembly (18) on

grease and position end frame to field frame so

the armature shaft.

that armature shaft enters bearing. Secure field

(2) To aid in reinstalling the snap ring (20)

frame and end frame to drive housing with two

and collar (21 ) on the armature shaft, proceed as

through bolts (15). Connect field leads to motor

follows. Place the collar (21 ) on the armature

terminal of solenoid with screw (4).

shaft with the cupped surface facing the snap ring

e. Installation and Testing. Refer to TM 10-

groove.

3930-633-12 for procedures covering installation

(3) Place the snap ring (20) on the end of the

and testing of the starter assembly.

shaft. With a piece of wood on top of ring, force

the ring over the shaft with a light hammer blow,

then slide the ring down into the groove.

Section III. IGNITION DISTRIBUTOR

3-7. General

the ignition timing at higher engine speeds or

heavy engine loadings to provide the correct

The distributor is equipped with both vacuum

ignition timing for maximum engine performance.

and centrifugal advance units. The vacuum

The advance mechanisms are independently

advance governs the ignition timing (spark

operated,

advance) during low engine speeds (RPM ) or low

a. Centrifugal Advance. The centrifugal ad-

engine loadings, The centrifugal advance, in

vance mechanism (fig. 3-8) is located below the

combination with the vacuum advance, controls

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |