|

|||

|

|

|||

|

Page Title:

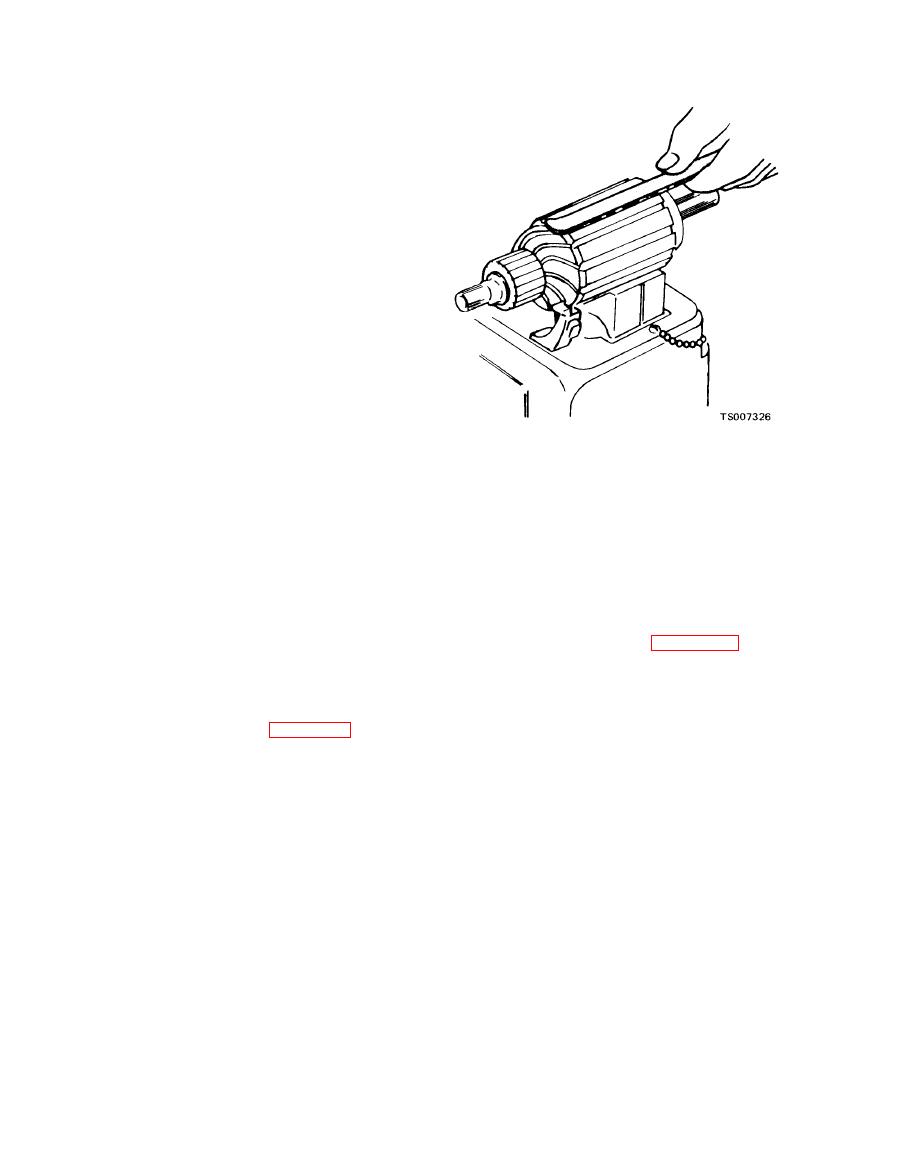

Figure 3-6. Testing for Shorts. |

|

||

| ||||||||||

|

|

TM 10-3930-633-34

(6) Remove the pinion from the armature by

sliding a metal cylinder onto the shaft; with a

hammer striking the metal cylinder against the

retainer, drive the retainer toward the armature

core and off the snap ring (20).

(7) Remove the snap ring (20) from the

groove in the armature shaft.

(8) Roll type drive pinion assemblies (18) are

designed to be serviced as a complete unit;

therefore, do not disassemble. If the condition of

the clutch assembly is questionable, replace it.

(9) A pole shoe spreader and pole shoe

screwdriver should be used if the field coils are to

be removed. Extra caution should be taken in

replacing the field coils to prevent grounding or

shorting when they are tightened in place. If the

pole shoe has a long lip on one side, it should be

assembled in the direction of armature rotation.

c. Inspection and Repair.

(1) Inspect the brushes for wear. If they are

worn down to one-half their original length, when

compared with a new brush, they should be

replaced. New brushes are ?/2, inch long.

(5) Opens are usually found where the

(2) Clean brush holders and be sure that the

conductors are joined to the commutator. Loose

brushes will not bind in the holders. The full

or poor connections will cause arcing and burning

length of the brush surface should ride on the

of the commutator. If the bars are not burned too

commutator with the proper spring tension (40

bad, resolder the leads in the riser bars and turn

ounces) to provide a good contact. Inspect the

the commutator down in a lathe. Then undercut

brush leads and screws to be sure they are tight

the insulation between the commutator bars 1/32

and clean.

inch .

(3) Inspect the armature to be sure there are

(6) Grounds in the armature can be found

no short circuits, opens, or grounds (see steps 4,

using a test lamp and prods, figure 3-7. If the

5 and 6 following).

lamp lights when one prod is positioned on the

(4) Short circuits are located by turning the

armature core or shaft, the armature is grounded.

armature in a growler while holding a steel strip

on the armature. The steel strip will vibrate on

the area of the short circuit. See figure 3-6.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |