|

|||

|

|

|||

|

Page Title:

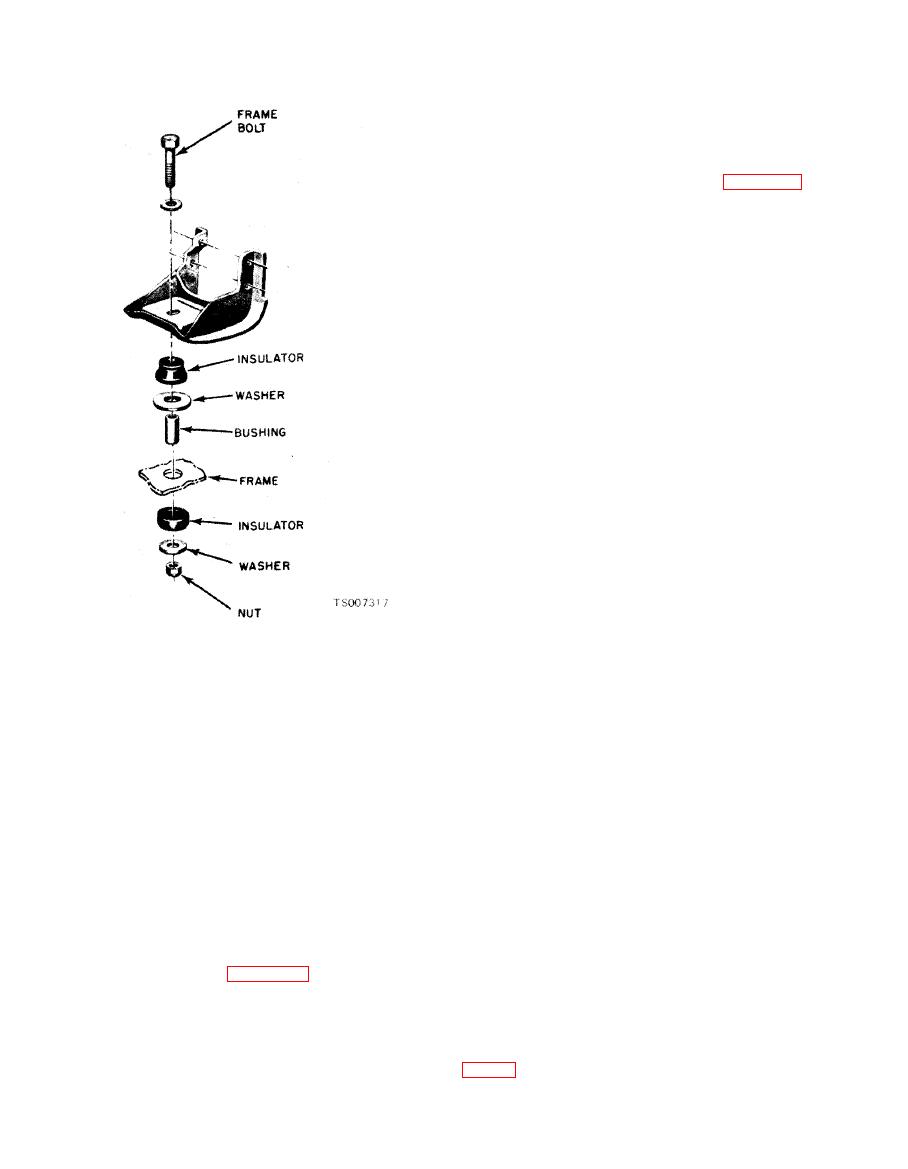

Figure 2-2. Engine Front Support. |

|

||

| ||||||||||

|

|

TM

10-3930-633-34

Lower engine fully on front support and remove

lifting sling.

(5) Install frame bolt and nut through engine

front support. Torque to 35 to 50 ft/lbs.

(6) Position the transmission oil filter

assembly on the bracket as shown in figure 2-1,

and install the three screws to secure filter to

bracket. Install clips over oil lines on engine

block.

(7) Install the starter (see TM 10-3930-633-

12). Connect starter cables, and install the

transmission filler tube bracket.

(8) Attach the exhaust pipe to the manifold

flange. Torque the nuts to 25 to 35 ft/lbs.

(9) Connect the engine ground strap.

(10) Connect the vacuum line at the intake

manifold. Connect the choke cable and accelerator

cables to the carburetor and anchor brackets. Be

sure the retracting spring is properly installed.

(11 ) Connect the engine wiring harness at

the coil, vacuum switch, coolant temperature

sender, and oil pressure sender.

(12) Install the alternator (see TM 10-3930-

633-12) but do not tighten mounting bolts.

(13) Install radiator (see TM 10-3930-633-

12). Connect oil cooler lines and install upper and

lower radiator hoses.

(14) Install fan pulley, fan belts and fan.

Torque fan bolts to 40 to 45 ft/lbs.

(15) Adjust fan belt tension and tighten

alternator mounting bolts (see TM 10-3930-633-

12).

(16) Install air cleaner ductwork. Connect

(18) Attach a sling to the engine or lifting

hose to fuel pump.

eyes, and tighten the hoist arrangement to bear

(17) Install and adjust hood.

most of the engine weight.

(18) Connect battery cables.

(19) Remove all converter housing to engine

(19) Fill and bleed cooling system. Fill the

attaching screws. Raise the engine slightly and

engine crankcase (see TM 10-3930-633-12). Start

slide forward to disengage crankshaft from torque

the engine check for leakage. Adjust idle speed

converter.

and mixture.

(20) Lift engine carefully and guide by hand

to avoid striking parts of the engine against the

2-25. Transmission

frame. If any resistance is felt, stop hoist im-

a. Removal.

m e d i a t e l y a n d investigate c a u s e before

(1) Remove the screws along the floor plate,

proceeding.

a n d lift off the transmission cover in the

b. Installation.

o p e r a t o r ' s compartment. Disconnecting the

accelerator pedal will simplify removal of the

pipe.

transmission cover.

(2) Lower the engine carefully into place on

(2) Disconnect the parking brake link from

the chassis. Make sure that front mount parts are

the brake lever mechanism, and swing the

arranged as shown in figure 2-2.

transmission cover up and out of the way.

(3) Observe the engine to transmission

(3) Disconnect the push-pull control cable at

converter housing flange and make sure that the

the transmission linkage on the side of the

converter pilot enters the crankshaft and that the

transmission case. Remove locknuts from cable

dowel pins in the engine block engage the con-

housing to free the cable from the anchor bracket

verter housing holes properly.

(4) Install engine to converter housing bolts.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |