|

|||

|

|

|||

|

Page Title:

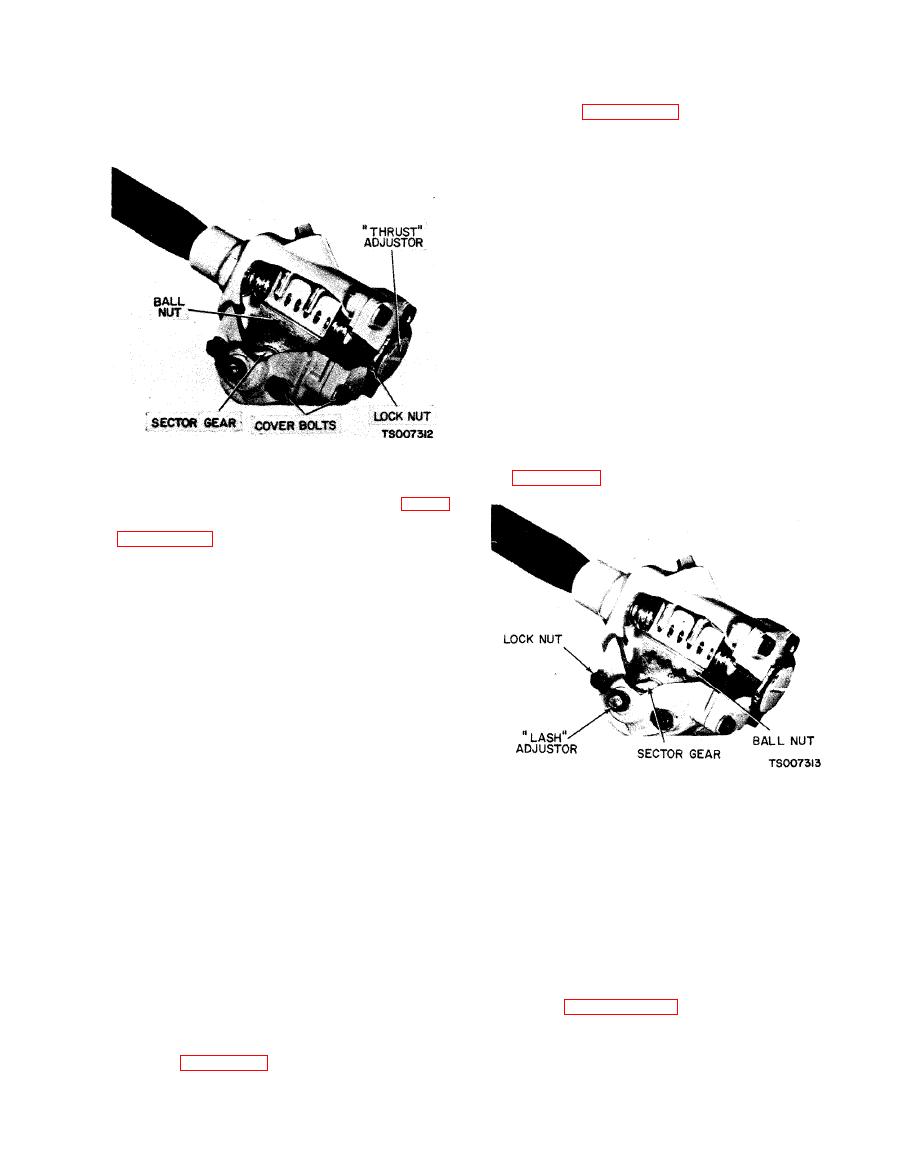

Figure 4-60. Steering Gear Thrust Adjustment |

|

||

| ||||||||||

|

|

TM 10-3930-633-12

bearings, loosen locknut and then turn worm

CAUTION

bearing adjuster nut clockwise until all end play is

Approach extreme ends cautiously;

removed see figure 4-60. Using spring scale, as

worm ball nut must not strike ends with

directed in step (2), check pull and readjust as

any degree of force.

necessary; then tighten locknut securely.

c. Sector Gear Lash Adjustment.

(1) Steering gear mechanism must be in

straight ahead position as previously explained.

(2) Turn lash adjuster screw clockwise to

remove all lash between gear teeth. Tighten

adjuster screw locknut. Position spring scale on

steering wheel so pull may be made at right

angles to wheel spoke.

(3) Measure pull while wheel is TURNED

THROUGH CENTER POSITION. Readjust if

reading is not within 2 to 3 pounds.

(4) Tighten adjuster screw locknut, check

pull again.

(5) After adjustments are made, install drag

link on pitman arm.

NOTE

If steering linkage adjustment is necessary, do not

install drag link to pitman arm. Refer to

b. Steering Gear Thrust Adjustment.

(1) Check tightness of cover bolts see figure

4-60. Loosen locknut and turn lash adjuster screw

see figure 4-61 counterclockwise a few turns to

provide clearance between sector gear and worm

ball nut.

(2) Turn steering wheel GENTLY to one

extreme end. Turn wheel back one full turn. With

spring scale on spoke of wheel, measure pull

required to KEEP WHEEL MOVING. Pull on

scale should be made at right angles to wheel

spoke. If pull is within 1 to 2 pounds, proceed

to lash adjustment in the following paragraphs. If

pull is not within 1 to 2 pounds, adjust worm

bearings. The pitman shaft adjustment must be

made if worm bearing check is accomplished, or if

the worm bearings are adjusted.

(3) If it is necessary to adjust the worm

Section XVIII. MAINTENANCE OF FRONT AXLE AND SPRINGS

4-89. Inspection

4-88. General

a. Check for bent front axle, loose or damaged

The front axle is a light truck type, being a solid

U-bolts at spring pads.

I-beam with front wheel steering spindles at-

b. Check springs for broken leaves, loose or

tached directly at each end. The axle is suspended

damaged spring shackles.

below the frame by means of semi-elliptical leaf

springs. The steering spindles are attached by

justment (paragraph 4-75).

means of king pins through the knuckle and axle.

d. Check steering linkage parts for physical

A thrust bearing is used between the lower face of

damage and secure attachment.

the axle and the steering knuckle to reduce

friction (see figure 4-62).

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |