|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-633-12

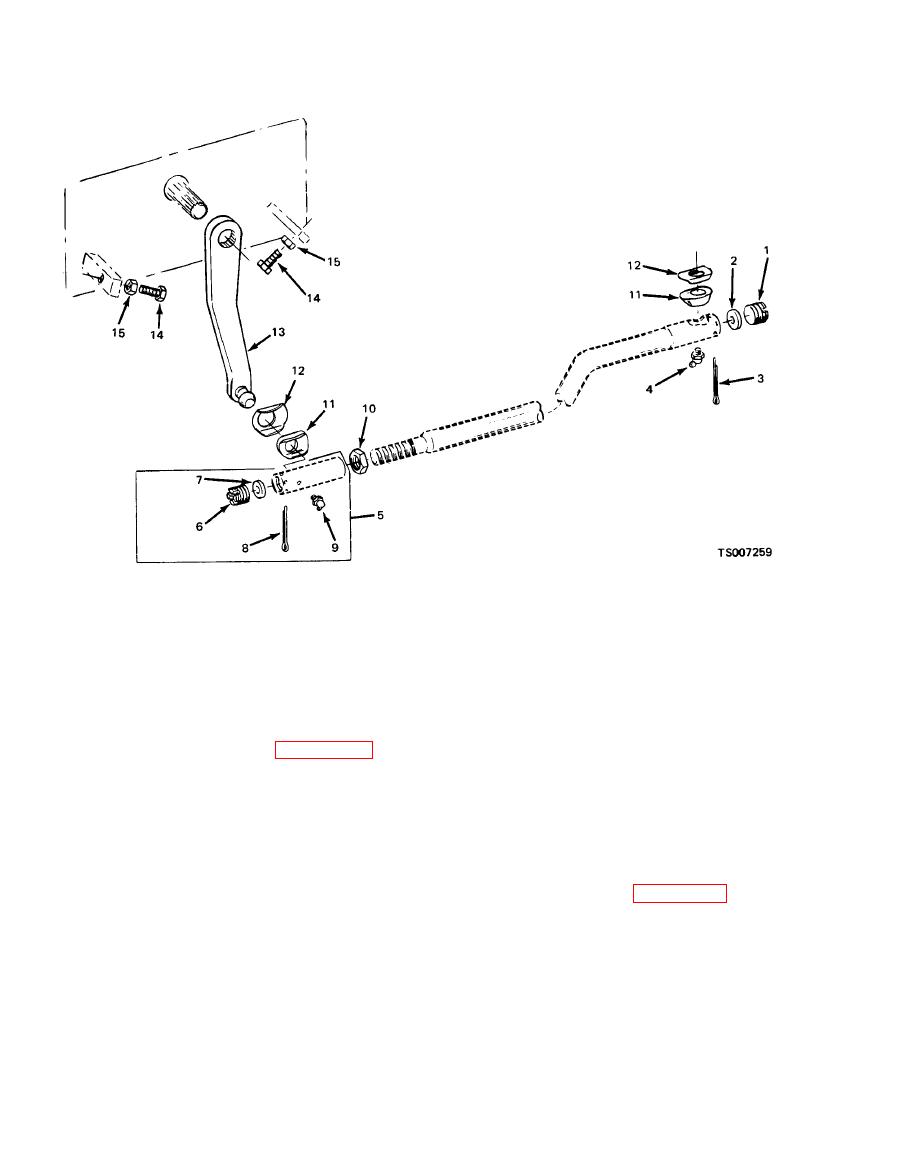

6. Adjusting plug

1. Adjusting plug

11. Seal

7. cup

12. Shield

2. cup

13. Pitman arm

3. Cotter pin

8. Cotter pin

14. Stop screw

4. Lubrication fitting

9. Lubrication fitting

15. Locknut

5. Socket assembly

10. Nut

d. Repair and Replacement.

a. Before making above adjustments, the

following preliminary operations" are necessary.

(1) Repair of the drag link consists of

replacement of any part see figure 4-59 found

(1) Disconnect steering drag link from

pitman arm. Note relative position of drag link

defective after removal and disassembly.

parts when disconnecting link so the parts may be

(2) TO remove the drag link, remove cotter

re-assembled correctly.

pin from each socket end, and loosen plugs until

(2) Check lubricant level. in steering gear

enough clearance is obtained to pull the sockets

housing. If low, add enough lubricant to bring

free of the ball studs.

level up to filler plug hole. See LO 10-3930-633-12.

(3) Further disassembly is accomplished as

(3) Tighten steering gear housing to frame

indicated by the exploded view illustration.

side member bolts. See figure 4-60.

(4) Adjust drag link overall length as

(4) Determine straight-ahead position of

outlined in the preceding paragraph before in-

steering mechanism by turning steering wheel to

stalling. Make certain both ball sockets are

extreme right. Then turn to extreme left,

properly lubricated. See LO 10-3930-633-12.

counting the exact number of turns from right to

left end. Turn wheel back one-half number of

Steering gear adjustments must be made ONLY

wheel turns. Mark wheel with respect to steering

as outlined in the following steps. Refer to figures

column so center position may readily be found

4-60 and 4-61. Always check worm bearing thrust

during adjustment procedures.

adjustment, and adjust if necessary, before

making sector gear lash adjustment.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |