|

|||

|

|

|||

|

Page Title:

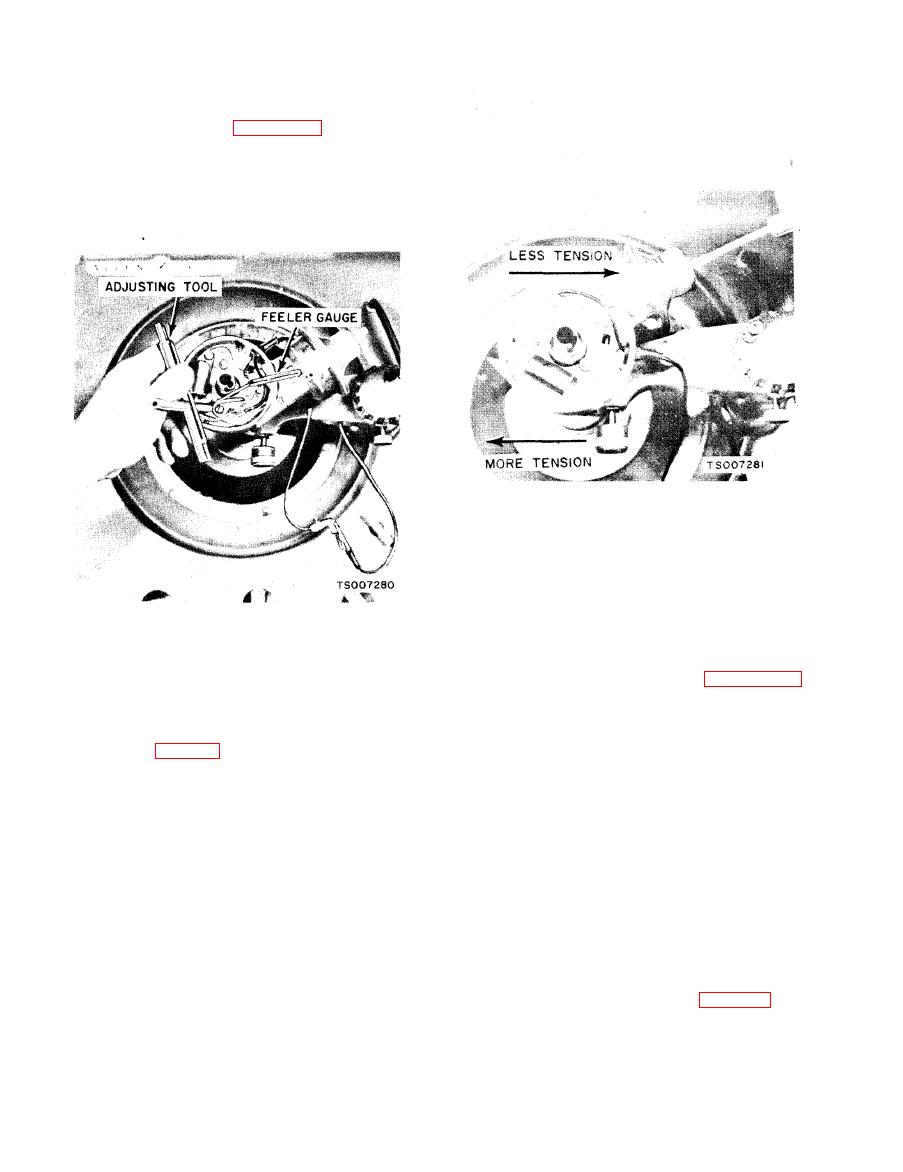

Figure 4-13. Adjusting Point Gap |

|

||

| ||||||||||

|

|

TM 10-3930-633-12

c. After aligning breaker points, adjust

breaker point gap to 0.024-0.026 inch. Use a wire

feeler gage as shown in figure 4-13 to check the

point opening. If the point gap is not 0.025 inch,

loosen the lock screw with a screwdriver and

position the adjusting plate of the point set until

the correct point opening is attained. Tighten the

lock screw.

The ignition timing mark is a stamped line on the

torque converter to flywheel flexplate. This line is

viewed through a hole in the engine rear cover-

plate, on the lower left side of the engine. A

rubber snap-in cover is used in this opening to

prevent entry of dust, dirt, and moisture. When

4-37. Breaker Point Spring Tension Adjustment

the cover is removed, the timing mark is viewed

through the hole as shown- in figure 4-15.

To check the spring tension, place the hooked end

Degree marks from TDC (0) to 14 (14 before top

of a spring tension gage over the movable breaker

dead center, No. 1 piston) are marked on the

point, then pull the gage at a right angle (900, to

engine rear coverplate. By connecting a timing

the movable arm until the breaker points just

light to the No. 1 (front) spark plug, and aiming

start to open (fig. 4-14). If the spring tension is

the light at the timing marks, the ignition timing

not between 17-21 ounces, it must be adjusted. To

can be determined and adjusted as required.

adjust the spring tension, proceed as follows:

Proceed as outlined below:

a. Clean and mark the timing marks with chalk

at. the breaker point assembly primary terminal.

or white paint.

b. Loosen the nut holding the spring in

b. Disconnect the vacuum line and plug the

posit ion. Move the spring toward the breaker arm

vacuum line to prevent leaks.

pivot to decrease tension and in the opposite

c. Connect a timing light to a terminal of the

direction to increase tension.

No. 1 cylinder spark plug wire. Connect

c. Tighten the locknut, then check spring

tachometer to the engine.

tension. Repeat the adjustment until the specified

d. Start the engine and reduce the engine idle

spring tension is obtained.

speed to 600 RPM to be sure that the centrifugal

advance is not operating. Adjust the initial

w i t h the lockwashers and tighten the nut

ignition timing to specifications (see table 4-4) by

securely.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |