|

|||

|

|

|||

|

Page Title:

Section VII. Maintenance of Positive Crankcase Ventilation System |

|

||

| ||||||||||

|

|

Section VII.

MAINTENANCE

OF

POSITIVE

VENTILATION

SYSTEM

4-19. General

f. Connect tube to fitting at rear of engine block

a n d to lower end of PCV valve. Tighten con-

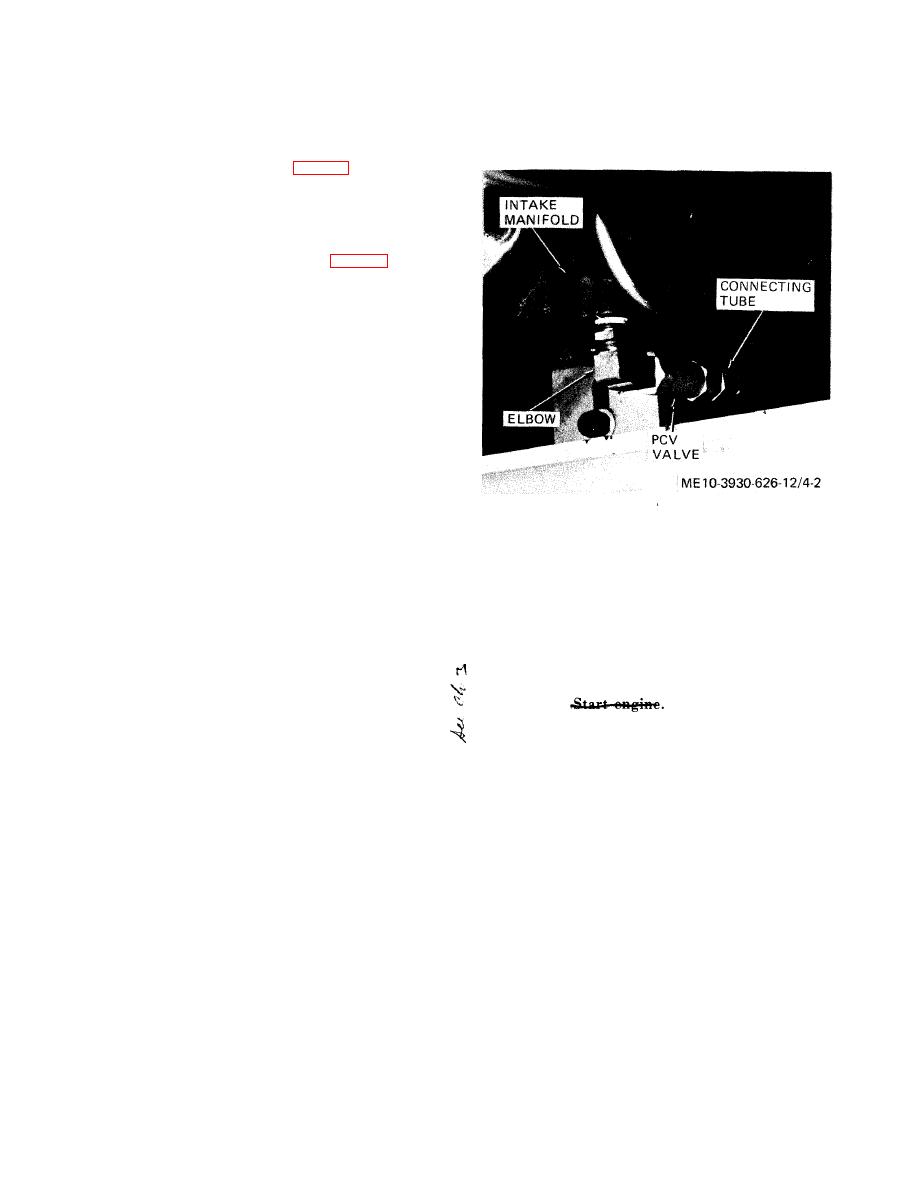

The positive crankcase ventilation valve

(PCV

nections securely.

valve) is located on the right side of the

engine

below the intake manifold (fig. 4-2). An

elbow

connects the valve to the intake manifold

and a

connecting tube connects the valve to the

engine

block.

4-20. Service and Replacement

lower end of PCV valve, then unscrew valve from

elbow.

b. Disconnect other end of connecting tube at

rear of engine block, and remove tube.

c. Thoroughly flush valve in both directions and

flush tube with SD (solvent, dry-cleaning, Fed.

Spec. P-S-661 ). Shake valve and tube vigorously to

remove cleaning solvent.

d. After cleaning, gently shake valve to determine

that check is free.

Note. Replace PCV valve if check is not free or if valve

shows evidence of internal corrosion.

e. Screw valve onto manifold elbow, being sure to

observe proper flow direction ( e n g i n e block to

manifold). Tighten securely.

Section V I I I .

MAINTENANCE

OF

BASIC

ENGINE

4-21. General

the condition of the piston rings and engine valves

An engine without fairly even compression in al

a. The engine is a six cylinder L-head unit, with

cylinders cannot be properly tuned.

battery ignition. The cooling system includes a

b. Procedure.

front-mounted water pump driven by a V -belt

(1) With shift lever in N (neutral) position,

from the crankshaft, a radiator mounted in front of

start engine.

Allow engine to run at

the engine, and a thermostat in the cylinder head

f a s t idle until reaching normal operating tem-

water outlet to maintain a constant efficient engine

perature.

operating temperature. The ignition system consists

(2) With engine warmed up, turn off ignition

of a coil, a conventional distributor, resistor spark

switch and remove spark plug wires from spark

plugs, the necessary wiring and cabling, and radio

plugs. Remove foreign matter from around spark

interference suppression components. The engine

plugs by blowing out with compressed air. Loosen

fuel system includes a mechanical fuel pump, a

spark plugs one complete turn. Reinstall spark plug

velocity governor, a downdraft singlebore car-

cables, and start and run engine at 1000 rpm for

buretor with air cleaner, and the required fuel lines

a p p r o x i m a t e l y 10 seconds to blow out carbon

and manifolding. Cylinder, spark plug and bearing

loosened by spark plug loosening.

numbering begins at the timing gear, or fan end, of

the engine.

Note. Blowing out carbon in this manner is important

in preventing false compression readings due to chips of carbon

b. This section of the manual covers those phases

lodging under the engine valves.

o f b a s i c engine maintenance which a r e the

(3) Turn off ignition switch to stop engine.

responsibility of organizational maintenance.

(4) Remove coil high tension lead from

distributor cap and ground lead to engine block.

a. General. P e r f o r m a c o m p r e s s i o n t e s t t o

(5) Remove spark plug leads from spark plugs,

determine the need of internal repairs before at-

and remove spark plugs from cylinder head.

tempting tune-up procedures. This test will indicate

(6) Fully open carburetor throttle and choke

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |