|

|||

|

|

|||

|

Page Title:

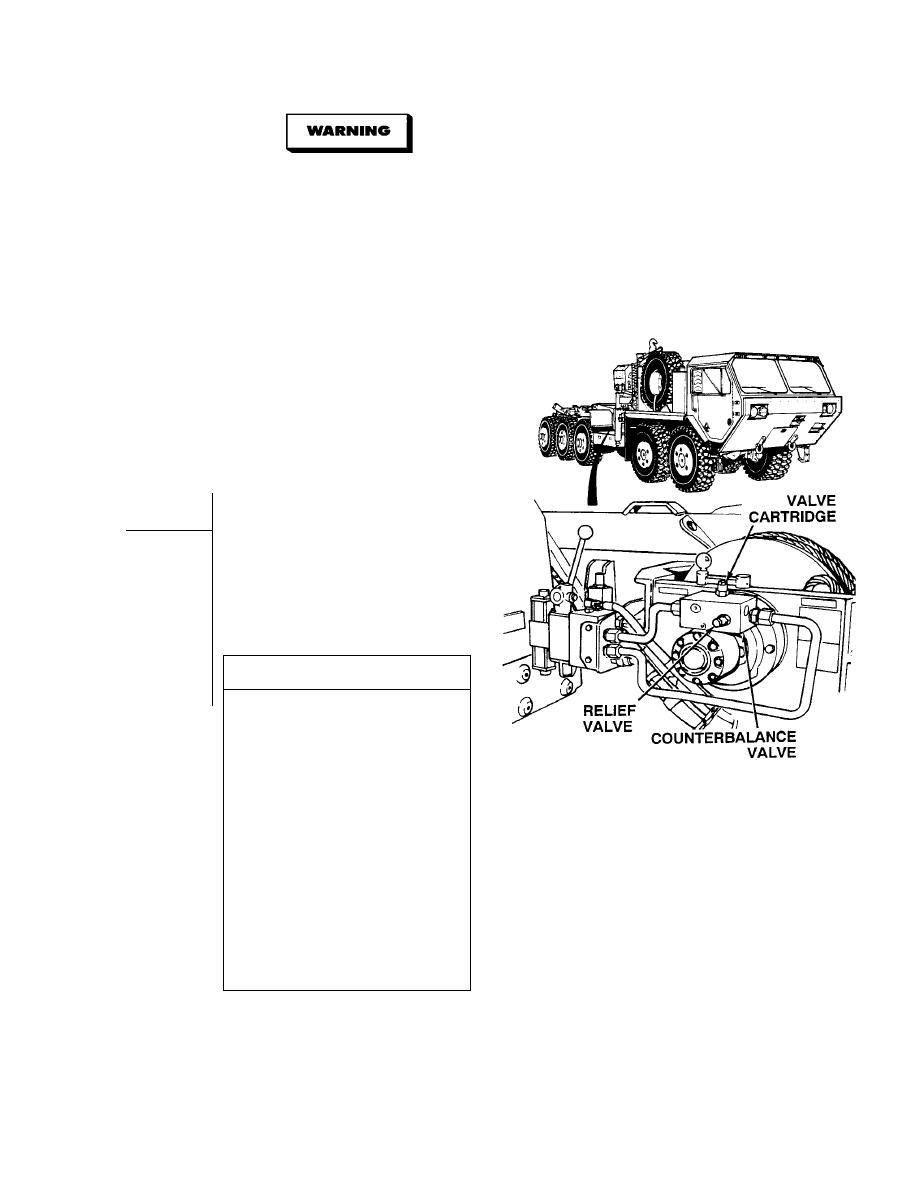

SELF-RECOVERY WINCH (SRW) DOES NOT OPERATE. (Cont) |

|

||

| ||||||||||

|

|

TM 9-2320-364-34-1

High pressure hydraulics [oil under 3700 psi

S

(25,512 kPa) pressure] operate this

equipment. Refer to truck operator and

maintenance manuals for hydraulic oil

pressure. Never disconnect any hydraulic line

or fitting without first dropping pressure to

zero. Failure to comply may result in injury to

personnel.

Fuel and oil are slippery and can cause falls.

S

To avoid injury, wipe up spilled fuel or oil with

rags.

Drycleaning Solvent (P-D-680) is TOXIC and

S

flammable. Wear protective goggles, face shield,

and gloves; use only in a well-ventilated area;

avoid contact with skin, eyes, and clothes, and

do not breathe vapors. Keep away from heat or

flame. Never smoke when using solvent. The

flashpoint for Type II Drycleaning Solvent is 140

degrees F (60 degrees C) and Type III

Drycleaning Solvent is 200 degrees F

(93 degrees C). Failure to do so may result in

injury or death to personnel.

If personnel become dizzy while using cleaning

S

solvent, immediately get fresh air and medical

help. If solvent contacts skin or clothes, flush

with cold water. If solvent contacts eyes,

immediately flush eyes with water and get

immediate medical attention.

NOTE

Use drain pan to catch leaking hydraulic oil.

VISUAL INSPECTION

(1) Remove relief valve from

counterbalance valve.

(2) Remove preformed packings and

backup rings from relief valve.

Discard preformed packings and

backup rings.

(3) Clean releif valve with drycleaning

solvent P-D-680.

(4) Using a non-metallic probe, manually

operate moving parts inside valve.

(a) If valve parts do not operate,

replace valve cartridge

(Para 16-36).

(b) If valve cartridge parts operate,

perform Steps (5) and (6) below

and replace SRW motor

(Para 16-35).

(5) Install preformed packings on relief

valve cartridge.

(6) Install relief valve cartridge in counter-

balance valve.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |