|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2320-364-34-1

High pressure hydraulics [oil under 3000 psi (20,685 kPa) pressure] operate this equipment. Refer to

vehicle operator and maintenance manuals for hydraulic oil pressure. Never disconnect any hydraulic

line or fitting without first dropping pressure to zero. Failure to comply may result in injury to personnel.

Fuel and oil are slippery and can cause falls. To avoid injury, wipe up spilled fuel or oil with rags.

NOTE

Use a drain pan to catch leaking hydraulic oil.

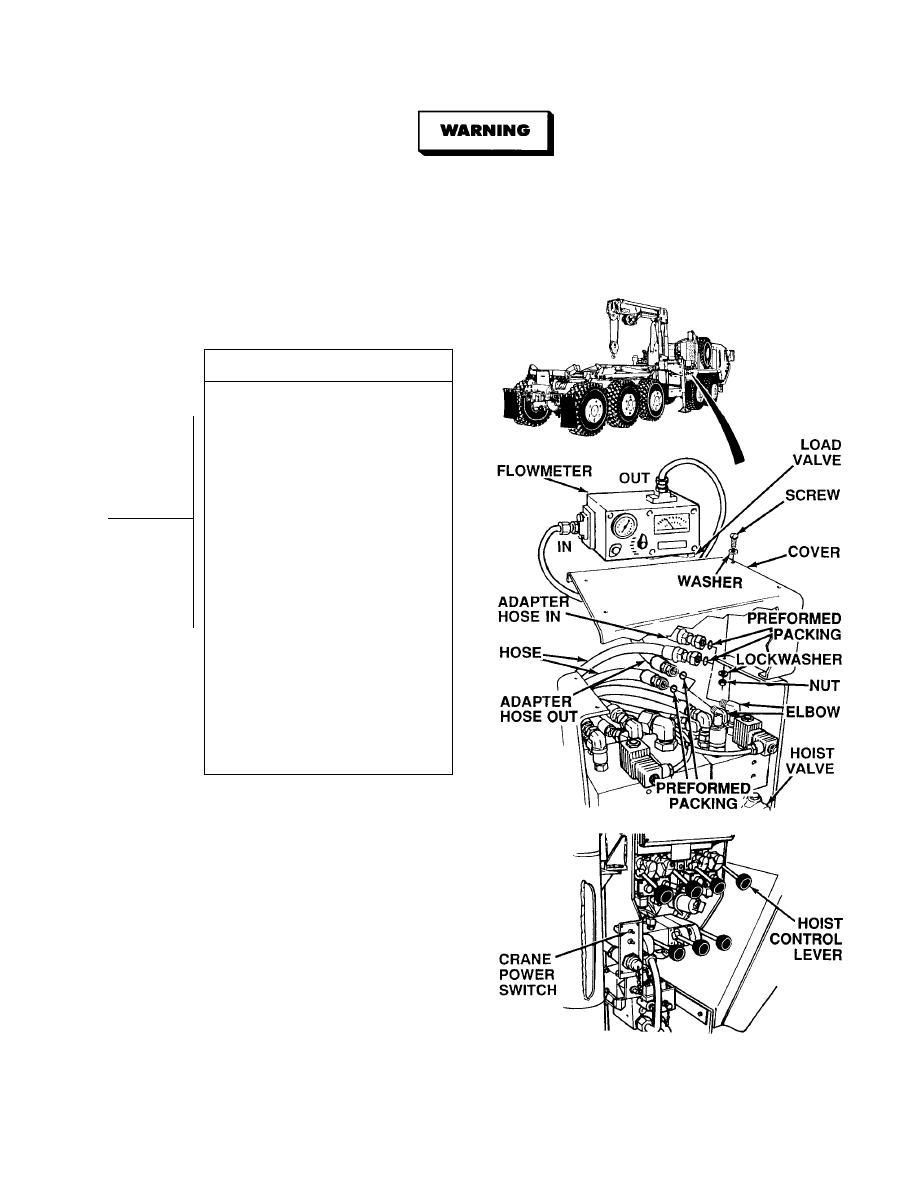

FLOWMETER TEST

(1) Loosen jam nut on hoist relief valve.

(2) Attempt to adjust hoist relief valve to

2100 psi (14,480 kPa) with flowmeter

pressure control valve closed and

HOIST control lever in UP position.

(a) If pressure cannot be adjusted to

2100 psi (14,480 kPa), perform

Steps (2) through (7) below and

repair relief valve in four valve

bank lift/hoist manifold

(Para 16-26).

(b) If pressure can be adjusted to

2100 psi (14,480 kPa), tighten

jam nut on relief valve and

perform Steps (2) through (7)

below.

(2) Open flowmeter load valve.

(3) Set crane POWER switch to OFF

position.

(4) Set hydraulic selector switch to OFF

position.

(5) Turn OFF ENGINE switch.

(6) Disconnect adapter hoses from

elbows. Discard preformed packings.

(7) Connect two hoses with preformed

packings to elbows.

(8) Install cover with four screws,

washers, lockwashers and nuts.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |