|

|||

|

|

|||

|

Page Title:

HOIST DOES NOT OPERATE OR OPERATES SLOWLY. |

|

||

| ||||||||||

|

|

TM 9-2320-364-34-1

2-15. MATERIAL HANDLING CRANE TROUBLESHOOTING (CONT).

18. HOIST DOES NOT OPERATE OR OPERATES SLOWLY.

INITIAL SETUP

Tools and Special Tools

Materials/Parts - Continued

Tool Kit, General Mechanic's

Lockwasher (4) (Item 282, Appendix E)

(Item 240, Appendix F)

Lockwasher (2) (Item 286, Appendix E)

Cap and Plug Set (Item 26, Appendix F)

Packing, Preformed (2) (Item 337, Appendix E)

Pan, Drain 4 gal (Item 144, Appendix F)

Packing, Preformed (2) (Item 345, Appendix E)

Pressure Test Kit (Item 165, Appendix F)

References

Wrench, Torque (0-175 lb-ft)

TM 9-2320-364-10

(Item 277, Appendix F)

TM 9-2320-364-20

Lifting Device (Minimum Capacity

200 lbs/91 kg)

Equipment Condition

Engine OFF, (TM 9-2320-364-10)

Materials/Parts

Parking brake applied, (TM 9-2320-364-10)

Oil, Hydraulic (Item 34, Appendix B)

Wheels chocked, (TM 9-2320-364-10)

Tags, Identification (Item 72, Appendix B)

Outriggers down with weight off

Gasket (Item 106, Appendix E)

vehicle suspension, (TM 9-2320-364-10)

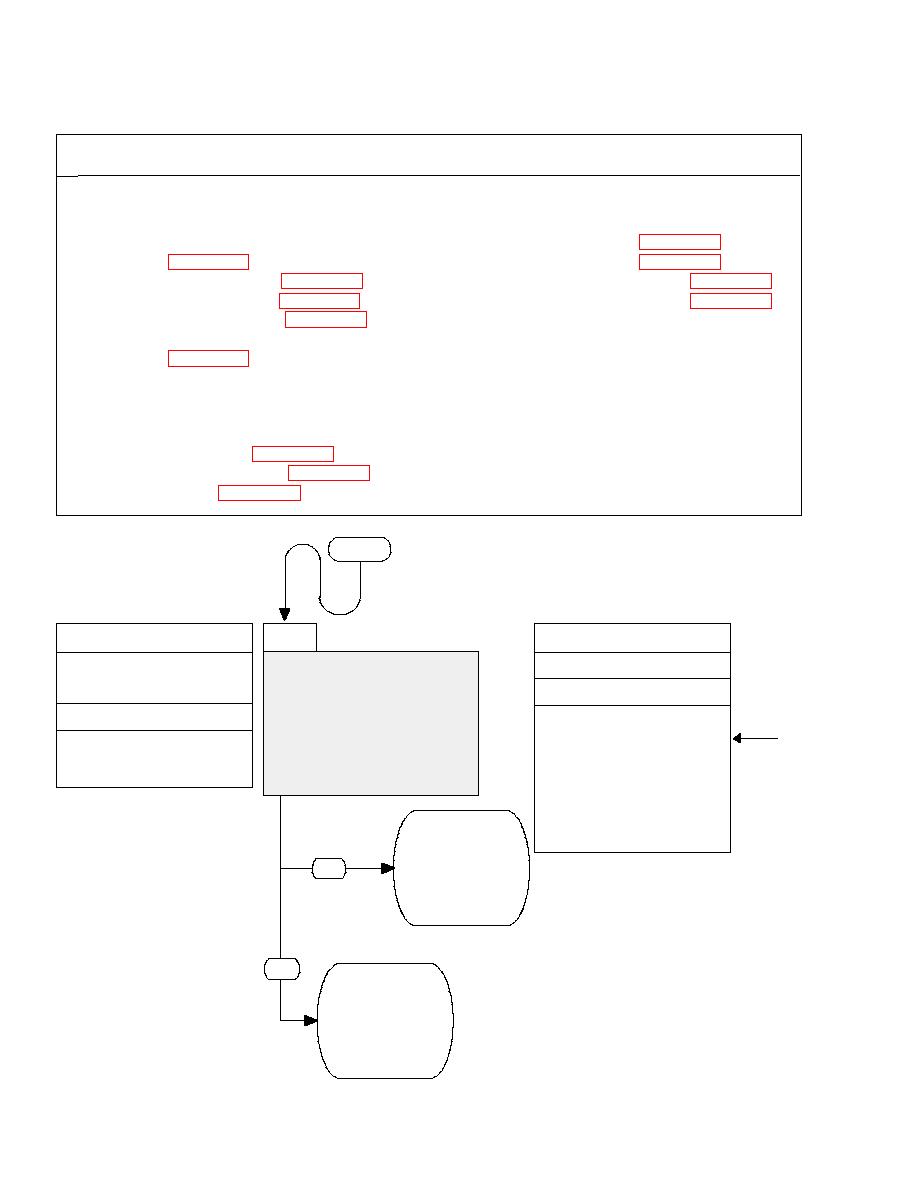

START

1.

KNOWN INFO

TEST OPTIONS

Unit Troubleshooting

Does hoist operate with

Operation test.

tasks completed.

BOOM control lever in UP

Boom lift operates.

REASON FOR QUESTION

position?

If load sense check valve in four

POSSIBLE PROBLEMS

valve bank lift/hoist manifold is

Four valve bank faulty.

faulty, pump compensator will

Hoist motor faulty.

not receive load sense pressure

Hoist assembly faulty.

from HOIST valve. If BOOM

control lever is held in the UP

position while attempting to

hoist, pump compensator will

sense load sense pressure from

BOOM valve.

Go to Step 2 of this

NO

Fault.

YES

Repair four valve

bank (Para 16-26).

Verify repair, go to

Step 5 of this Fault.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |