|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2320-364-34-1

High pressure hydraulics [oil under 3000 psi (20,685 kPa) pressure] operate this equipment. Refer to

vehicle operator and maintenance manuals for hydraulic oil pressure. Never disconnect any hydraulic

line or fitting without first dropping pressure to zero. Failure to comply may result in injury to personnel.

Fuel and oil are slippery and can cause falls.

To avoid injury, wipe up spilled fuel or oil

with rags.

Do not work on any item supported only by lift

jacks or hoist. Always use blocks or proper

stands to support the item prior to any work.

Equipment may fall and cause injury or death

to personnel.

NOTE

Use a drain pan to catch leaking hydraulic oil.

Fluid laying in hose and fitting should drain

quickly and then stop. Hose may drain more

fluid for a longer period of time than fitting.

VISUAL INSPECTION

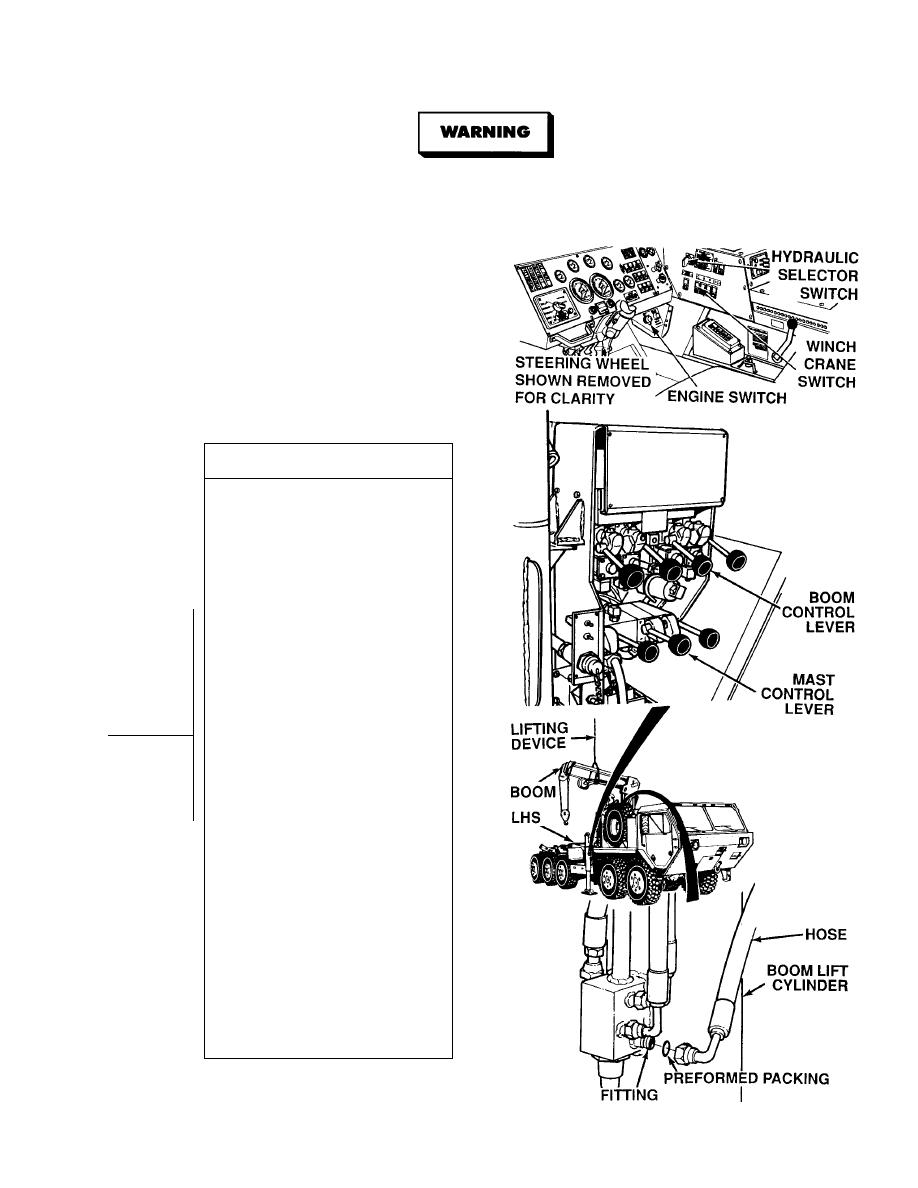

(1) Start engine (TM 9-2320-364-10).

(2) Set WINCH/CRANE switch to

CRANE position.

(3) Set hydraulic selector switch to

CRANE/SRW position.

(4) Set crane POWER switch to

ON position.

(5) Raise boom until approximately

level with ground using BOOM

control lever.

(6) Raise mast completely using MAST

control lever.

(7) Attach lifting device to boom and

support boom.

(8) Disconnect hose from fitting at

bottom of boom lift cylinder on LHS

side of crane. Discard preformed

packing.

(9) Allow boom to creep down with

lifting device. Do not remove lifting

device from boom.

(10) Allow fluid laying in hose and fitting

to drain out.

(a) If no hydraulic fluid drains from

fitting or hose after fluid laying in

fitting and hose has drained out,

perform Steps (11) through (18)

below and go to Step 2 of this

Fault.

(b) If fluid continues to drain from

fitting or hose as boom creeps

down, that cylinder is faulty.

Fluid from leaking load control

valve will continue to leak from

hose or fitting as long as

cylinder is allowed to creep

down. Perform Steps (11)

through (18) below and replace

holding valve that continues to leak

hydraulic fluid (Para 16-7).

Continued on next page.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |