|

|||

|

|

|||

|

Page Title:

LHS DOES NOT OPERATE OR OPERATES SLOWLY. (Cont |

|

||

| ||||||||||

|

|

TM 9-2320-364-34-1

The LHS hydraulic system operates at oil

S

pressures up to 3675 psi (25,339 kPa).

Never disconnect any hydraulic line or

fitting without first dropping pressure

to zero. Failure to comply may result in

serious injury or death to personnel.

Fuel and oil are slippery and can cause

S

falls. To avoid injury, wipe up spilled

fuel or oil with rags.

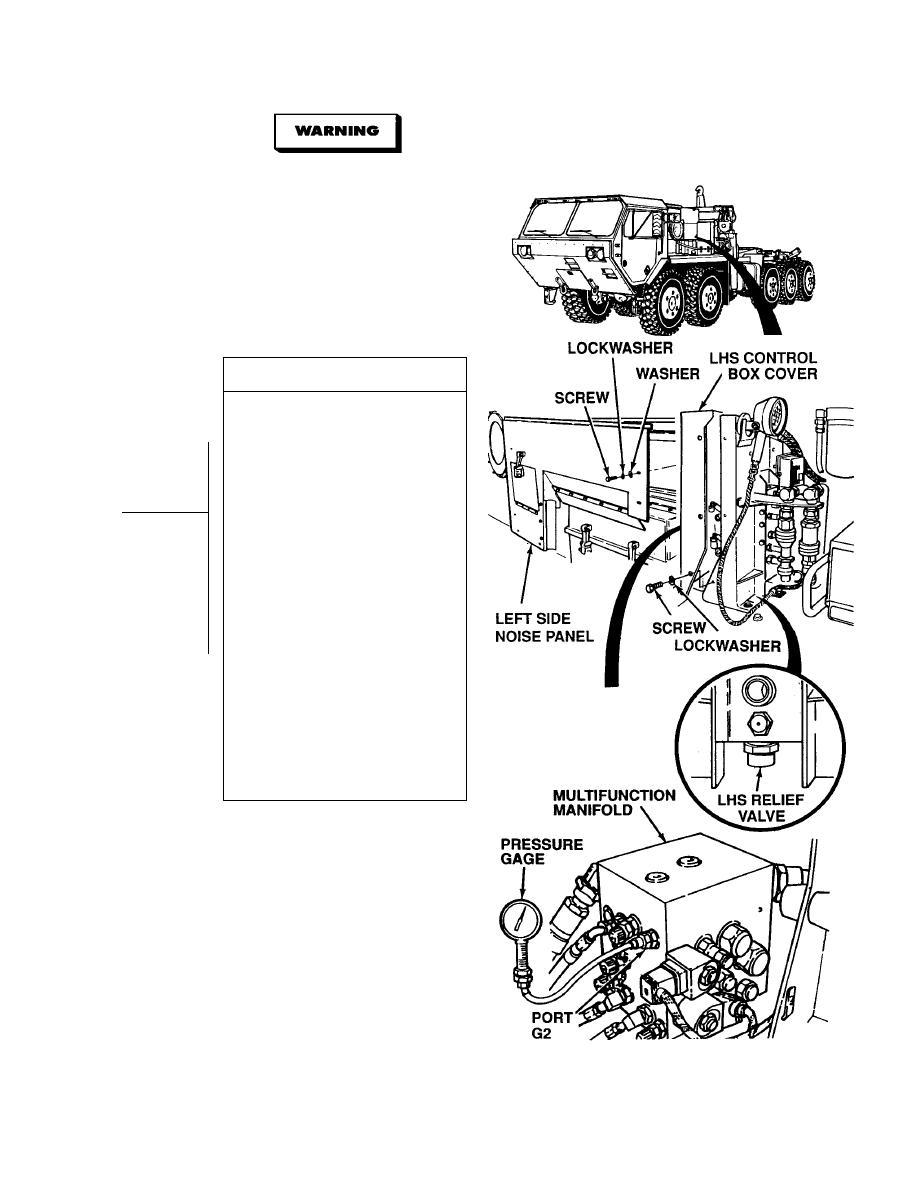

PRESSURE TEST

(1) Connect 0 to 6000 psi (0 to 41,370 kPa)

pressure gage to multifunction

manifold, port G2.

(2) Start engine (TM 9-2320-364-10).

(3) Set hydraulic selector switch to

AUTO position.

(4) Adjust LHS relief valve while

observing pressure gage connected

to port G2.

(a) If pressure cannot be adjusted

up to 3600 to 3625 psi

(24,822 to 24,994 kPa) using LHS

relief valve, perform Steps (5)

through (7) below and replace

LHS relief valve (Para 17-8).

(b) If pressure can be adjusted up

using LHS relief valve, fault not

corrected. Perform Steps (5)

through (9) below and notify

supervisor.

(5) Set hydraulic selector switch to OFF

position.

(6) Turn OFF ENGINE switch.

(7) Disconnect pressure gage from

multifunction manifold.

(8) Install left side noise panel, eight

washers, lockwashers, and screws.

(9) Install four screws, lockwashers and

LHS control box cover.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |