|

|||

|

|

|||

|

Page Title:

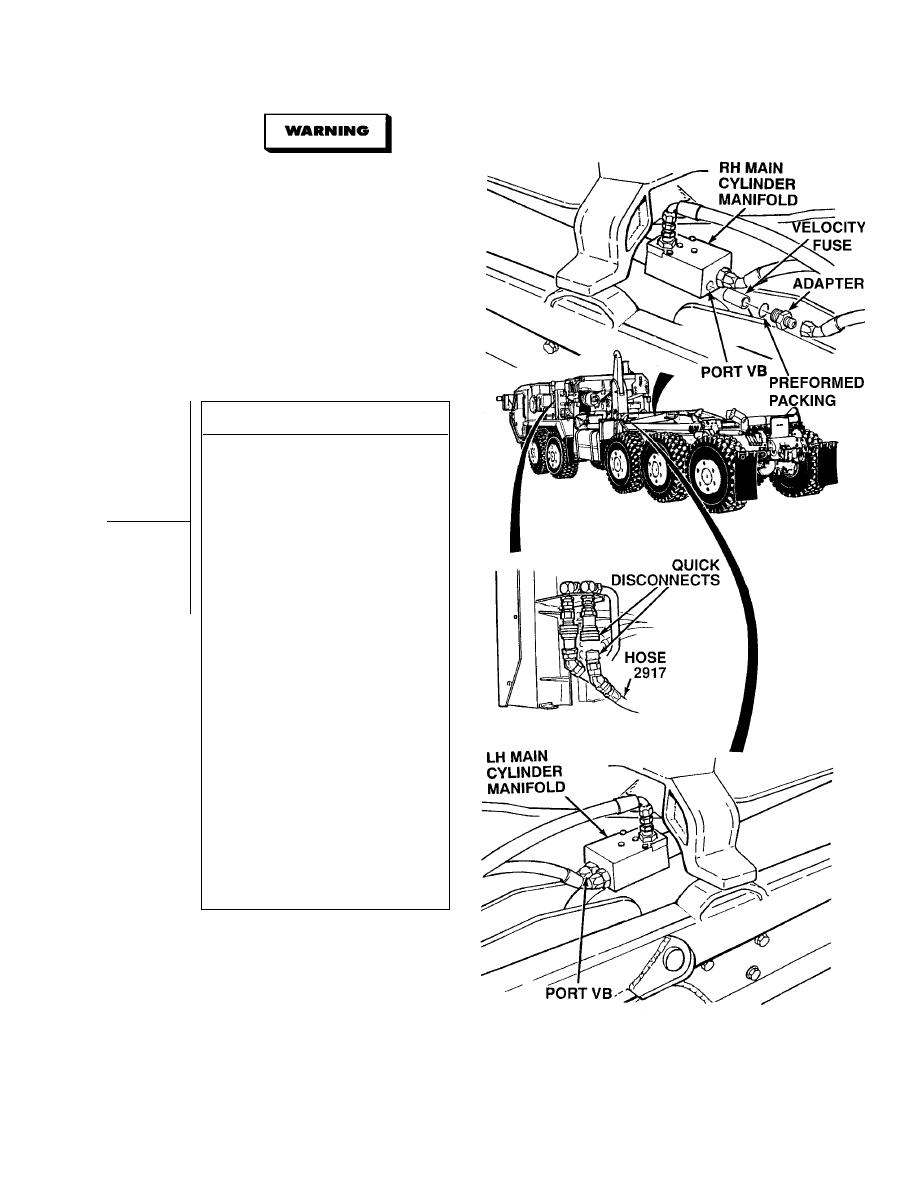

MIDDLE FRAME DOES NOT OPERATE. (Cont) |

|

||

| ||||||||||

|

|

TM 9-2320-364-34-1

The LHS hydraulic system operates at oil

S

pressures up to 3675 psi (25,339 kPa).

Never disconnect any hydraulic line or

fitting without first dropping pressure

to zero. Failure to comply may result in

serious injury or death to personnel.

Fuel and oil are slippery and can cause

S

falls. To avoid injury, wipe up spilled

fuel or oil with rags.

Compressed air used for cleaning purposes

S

will not exceed 30 psi (207 kPa). Use only

with effective chip guard and personal

protective equipment (goggles/shield, gloves,

etc.). Failure to comply may result in injury

to personnel.

VISUAL INSPECTION

(1) Disconnect hose 2917 male quick

disconnect from LHS control box

female quick disconnect.

(2) Disconnect hose from LH main

cylinder manifold, port VB adapter.

(3) Plug hose using metal plug.

(4) Remove LH main cylinder

manifold (Para 17-16).

(5) Remove adapter and velocity fuse

from main cylinder manifold,

port VB.

(6) Remove preformed packing from

adapter. Discard preformed

packing.

(7) Blow compressed air into velocity

fuse.

(a) If air cannot be blown through

velocity fuse, replace velocity

fuse.

(b) If air can be blown through

velocity fuse, velocity fuse is OK.

(8) Lubricate preformed packing with

hydraulic oil and install on adapter.

(9) Install velocity fuse and adapter with

new preformed packing in main

cylinder manifold.

(10) Install main cylinder manifold

on main cylinder.

(11) Install hose on main cylinder

manifold adapter port VB.

(12) Repeat Steps (2) through (11) above

for RH main cylinder manifold.

(13) Connect quick disconnect

hose 2917.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |