|

|||

|

|

|||

|

Page Title:

ENGINE STALLS WHEN TRANSMISSION IS SHIFTED INTO GEAR. (Cont) |

|

||

| ||||||||||

|

|

TM 9-2320-364-34-1

Adhesives, solvents, and sealing compounds can burn easily, can give off harmful vapors, and are

harmful to skin and clothing. To avoid injury or death, keep away from open fire and use in well-ventilated

area. If adhesives, solvent, or sealing compound gets on skin or clothing, wash immediately with soap and

water.

Fuel and oil are slippery and can cause falls. To avoid injury, wipe up spilled fuel or oil with rags.

Due to limited work area, be prepared with suitable container to catch approximately one quart of oil when

removing lube oil pressure port plug, or hose for pressure gage, from underside of torque converter

housing, personnel can become wet with oil.

NOTE

Use a drain pan to catch leaking hydraulic oil.

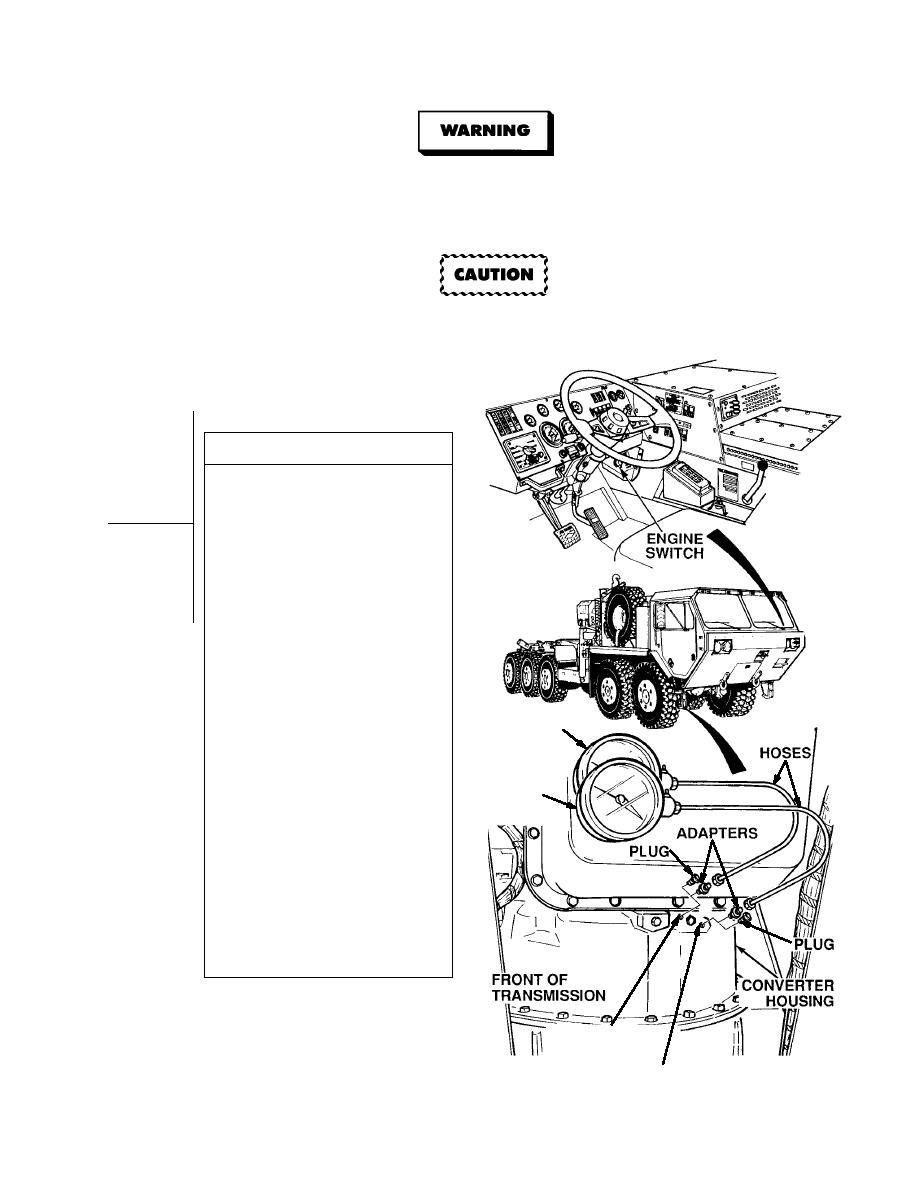

PRESSURE TEST

(1) Remove plugs from "non active" and

"lockup" ports of converter housing.

(2) Install 1/8 in. NPT adapters, from

pressure test kit, in "nonactive" and

"lockup" ports of converter housing.

(3) Install 5 ft. (1.5 m) hose from kit, on

adapter in "non active" port and

0 to 160 psi (1,103 kPa) gage

on hose. Extend hose out from

under truck.

(4) Install 8 ft. (2.4 m) hose from kit on

adapter in "lockup" port and

0 to 2000 psi (13,790 kPa) gage

on hose. Extend gage out from

under truck.

(5) Start engine (TM 9-2320-364-10) and

allow to run at idle speed while

assistant reads pressure gages.

0-160 PSI

(a) If pressure is between 150 to

PRESSURE

160 psi (1,034 kPa to 1,103 kPa)

GAGE

on both gages, lockup shift valve

is OK, replace ATEC ECU, (TM 9-

2320-364-20).

0-2000 PSI

(b) If pressure is between 150 to

PRESSURE

160 psi (1,034 kPa to 1,103 kPa)

GAGE

on gage hooked up to "lockup" port,

and no pressure is shown on gage

hooked up to "non active" port, replace

lockup shift valve (Para 23-12).

(6) Turn OFF engine switch.

(7) Remove gages, hose, and adapters

from "lockup" and "non active" ports

of converter housing.

(8) Apply thread sealing compound and

install plugs in lubrication ports of

converter housing. Tighten plugs to

48 to 60 lb-in (5.4 to 6.8 N.m).

NON ACTIVE

PORT

LOCKUP PORT

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |