|

|||

|

|

|||

|

Page Title:

LOW ENGINE OIL PRESSURE (LESS THAN 5 PSI [34 KPA] AT IDLE, LESS THAN 40 PSI [276 KPA] DURING NORMAL OPERATION). (Cont) |

|

||

| ||||||||||

|

|

TM 9-2320-364-34-1

Allow engine to cool before performing troubleshooting maintenance. If necessary use insulated pads

and gloves. Hot engine components will burn and cause injury to personnel.

Drycleaning Solvent (P-D-680) is TOXIC and flammable. Wear protective goggles, face shield, and gloves; use

only in a well-ventilated area; avoid contact with skin, eyes, and clothes, and do not breathe vapors. Keep away

from heat or flame. Never smoke when using solvent. The flashpoint for Type II Drycleaning Solvent is 140

degrees F (60 degrees C) and Type III Drycleaning Solvent is 200 degrees F (93 degrees C). Failure to do so

may result in injury or death to personnel.

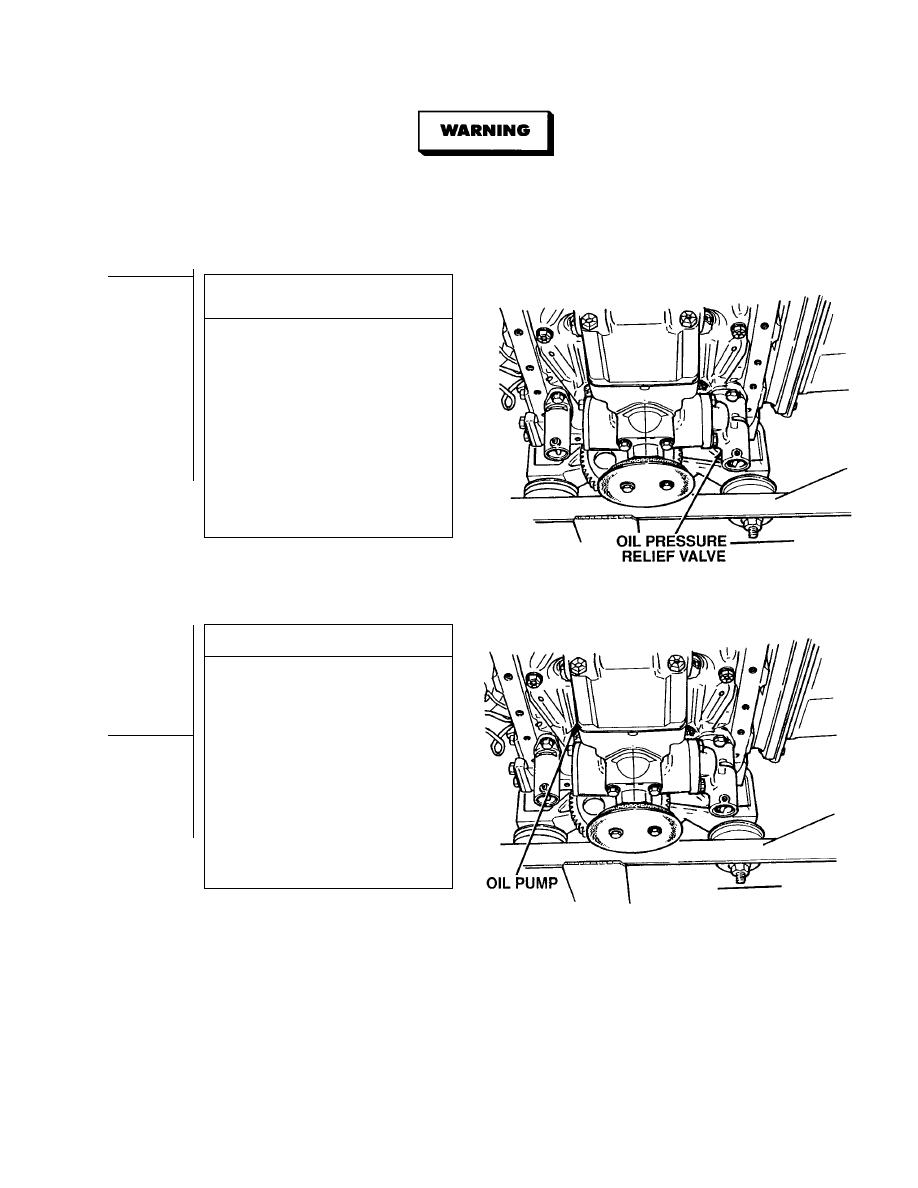

OIL PRESSURE RELIEF VALVE

INSPECTION

(1) Remove oil pressure relief valve

(Para 3-28).

(2) Clean oil pressure relief valve with

drycleaning solvent.

(3) Check valve inside oil pressure

relief valve for sludge, scoring, and

not closing.

(a) If valve has sludge on it, clean

valve with drycleaning solvent.

(b) If valve is scored or not closing

completely, replace oil pressure

relief valve (Para 3-28).

(c) If valve is not scored and closes

completely, go to Step 5 of this

Fault.

VISUAL INSPECTION

(1) Remove engine oil pump (Para 3-26).

(2) Clean engine oil pump with

drycleaning solvent.

(3) Check engine oil pump for sludge,

broken gear teeth, or other damage.

Make sure pump turns freely.

(a) If oil pump is damaged, replace

oil pump.

(b) If oil pump is not damaged, oil

pump is OK.

(4) Install engine oil pump (Para 3-26).

(5) Install oil pressure relief valve

(Para 3-28).

(6) Install oil pressure regulator valve

(Para 3-27).

(7) Install engine oil pan (Para 3-22).

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |