|

|||

|

|

|||

|

Page Title:

ENGINE OVERHEATS (WATER TEMPERATURE GAGE CONTINUOUSLY READS OVER 230F [110C]). (Cont) |

|

||

| ||||||||||

|

|

TM 9-2320-364-34-1

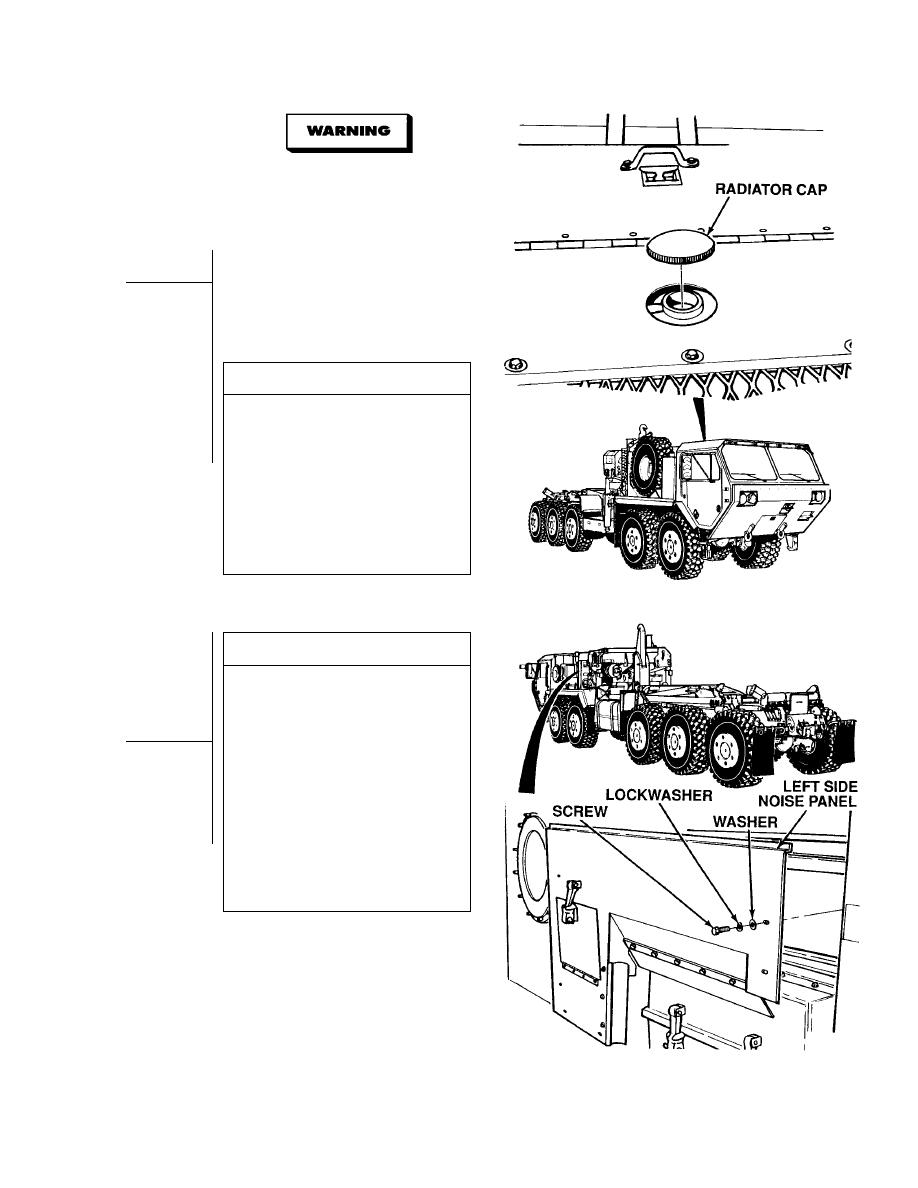

Allow engine to cool before performing

troubleshooting maintenance. If necessary

use insulated pads and gloves. Hot engine

components will burn and cause injury to

personnel.

Do not remove the radiator cap when the

engine is hot; steam and hot coolant can

escape and burn personnel.

Use a clean, thick waste cloth or like

material to remove the cap. Avoid using

gloves. If hot water soaks through gloves,

personnel could be burned.

CYLINDER HEAD INSPECTION

(1) Start engine, (TM 9-2320-364-10).

(2) Remove radiator cap and check for

bubbles.

(a) If bubbles are seen, perform

Steps (3) and (4) below and

replace cylinder head gaskets

or cylinder head(s), (Para 3-7).

(b) If bubbles are not seen, perform

Steps (3) and (4) below and go to

Step 4 of this Fault.

(3) Turn OFF ENGINE switch.

(4) Install radiator cap.

VERIFY REPAIR

(1) Start engine, (TM 9-2320-364-10) and

allow it to run until engine

temperature stabilizes.

(a) If water temperature gage

continuously reads over 230F

(110C), fault not corrected.

Perform Steps (2) through (4)

below and notify supervisor.

(b) If water temperature gage

continuously reads under 230F

(110C), fault has been corrected.

(2) Turn OFF ENGINE switch.

(3) Install left side noise panel with

eight washers, lockwashers and

screws.

(4) Install right side noise panel,

(TM 9-2320-364-20).

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |