|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2320-364-34-1

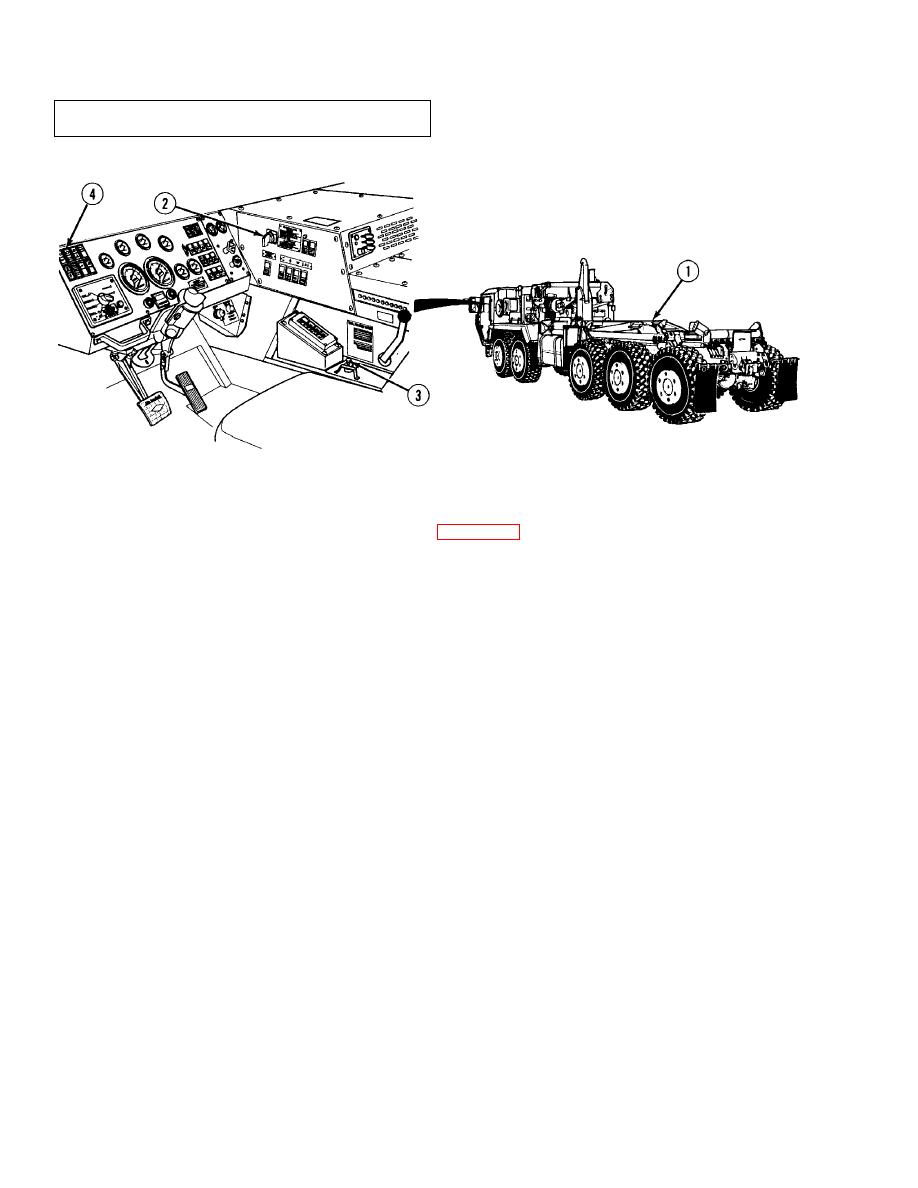

STEERING WHEEL

SHOWN REMOVED

FOR CLARITY

The truck is equipped with a Load Handling System (LHS) (Figure 1-25). The LHS (1) is fully hydraulic, powered by

the truck hydraulic system and is operated by hydraulic selector switch (2) and joystick (3) located to the driver's right

in the truck cab. The LHS control system is electrically powered from the truck electrical system. The LHS is capable

of the following, with a flatrack (FR) loaded with 33,000 lb. (15 metric tons) nominal payload:

Loading/unloading the FR from the truck to 12 in. (30.5 cm) below ground level and any intermediate level,

Loading/unloading from uneven ground slopes of 10 degrees from the trucks lateral and horizontal axis,

Loading/unloading to/from the trailer or ramps in which the height is equal to or less than the height from the

ground to the bottom of the FR (while on the truck).

a. Flatrack Locking. The LHS is designed with automatic locking features that secure the FR for all modes of

transportation. The LHS can automatically guide, center and secure a FR to the truck so that even during rough trail

operations, the FR remains safely secured.

b. LHS Overload. The LHS will not function when the payload exceeds 36,300 lbs. (16,480 kg) maximum. A

warning light (4), located in the cab in plain view of the driver, activates when a FR with a payload between 34,500 and

35,500 lbs. (15,663 to 16,117 kg) is being loaded by the LHS while under the worst conditions.

c. Hydraulic System. Hydraulic filters are located to provide direct access and to allow removal without damage

to the truck. By-passes are furnished where necessary to protect filters during cold temperature operation. All

cylinder rods exposed during operation have a hard chromium plating.

connectors are provided so that one PLS truck can readily hydraulically power the LHS of another PLS truck.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |