|

|||

|

|

|||

|

Page Title:

Table 2-1. Unit Level Preventive Maintenance Checks and Services (PMCS) (CONT). |

|

||

| ||||||||||

|

|

TM 9-2320-364-20-1

Table 2-1. Unit Level Preventive Maintenance Checks and Services (PMCS) (CONT).

Item

Interval

Item to Be

Procedure

Not Mission

No.

Inspected

Capable If:

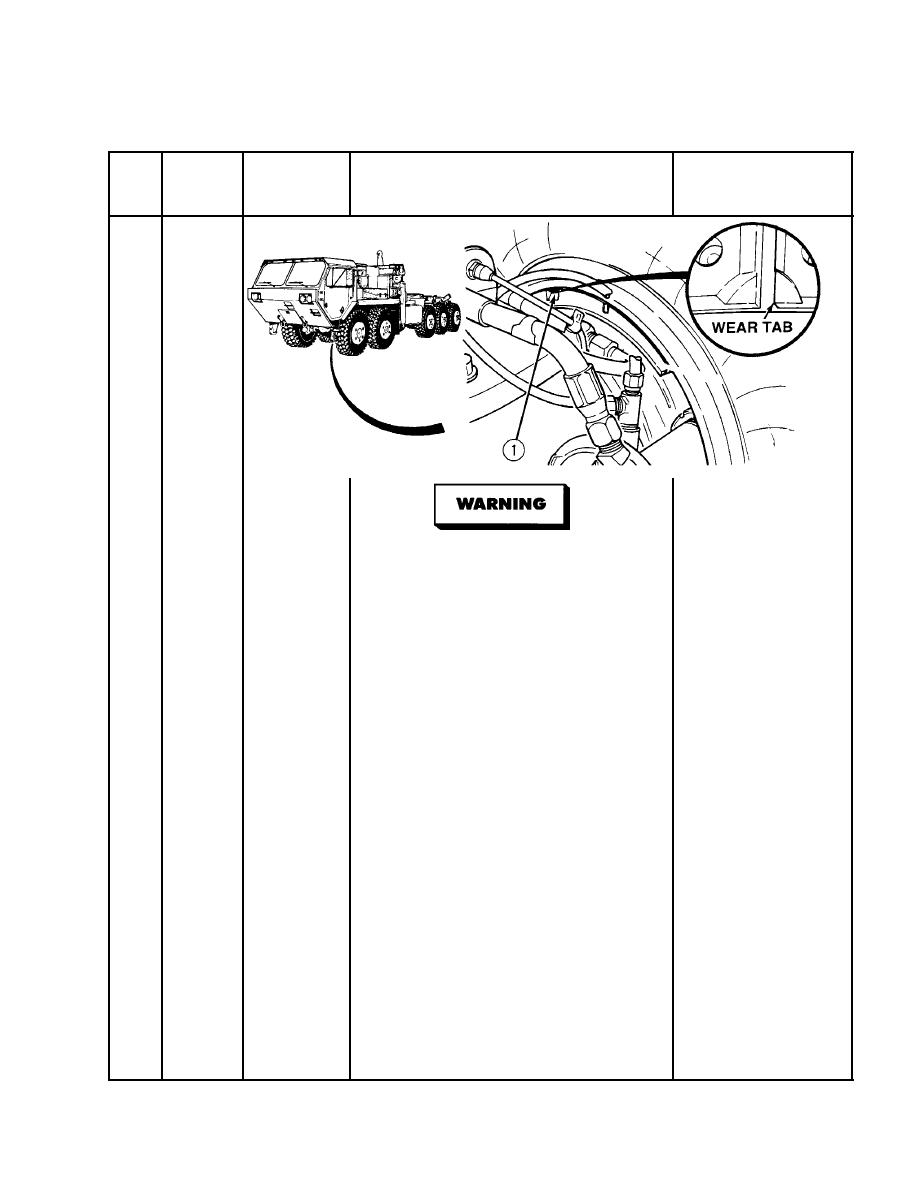

Brake drum can get very hot during vehicle

operation. Place hand near drum to check

for excessive heat, but do not touch. Failure

to comply may result in injury to personnel.

Apply truck brakes and chock wheels

before any maintenance tasks are

performed. Otherwise serious injury to

personnel could result.

19

Semi-

Brakes

a. Carefully check and compare each brake

a. Brake drums are

Annual

(all axles)

drum for overheating which can indicate a

overheated or excessive-

dragging brake. Cool brake drum could mean

ly cool.

improper adjustment, defective, or inoperative

brakes.

NOTE

Brake assembly must be cleaned of dirt, mud

and debris before starting inspection.

b. Check brake shoe linings for grooves,

b. Brake shoes show

uneven wear, signs of overheating and

signs of wear, overheat-

thickness. If step on center edge wear tab (1)

ing or distortion.

of brake shoe lining is not visible or 1/4 in. (6

mm) thick or less on any part of brake shoe, or

there are signs of overheating, replace brake

shoes. Refer to Para 12-2.

c. Check brake supply lines and brake vent

c. Any Class III leaks

lines for cracks, bends, breaks or looseness.

are found.

Tighten loose parts if leaking. Replace lines or

hoses if damaged. Refer to Para 12-36.

2-23

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |