|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2320-360-34-2

27-2.1. AUXILIARY STEERING PUMP REPAIR (CONT)

(6) Inspect yoke face for wear, roughness, and scoring.

(7) Inspect shaft for wear, roughness, and scoring.

NOTE

Wobble shoe plate to ensure that each piston is free within its bore in the cylinder

block.

(8) Check cylinder block bore for excessive wear. Piston should be close fit but slide in and out easily. If

binding exists, clean and lubricate block and piston with clean hydraulic fluid. If binding persists, replace

cylinder block.

(9) Check for end play between piston and shoe.

NOTE

Piston face thickness dimensions must be within 0.001 in.

(0.025 mm) of each

other.

(10) Measure thickness of nine piston faces.

NOTE

Pins, bearings, and races are replaced in sets. If one is defective, replace both.

(11) Inspect pins for equal length and bent condition. Replace if damaged.

(12) Remove burrs from pin retainer.

(13) Inspect bearings for scoring, pitting, and roughness when turned in race. Replace if: damaged.

(14) Inspect bearing spacers for burrs.

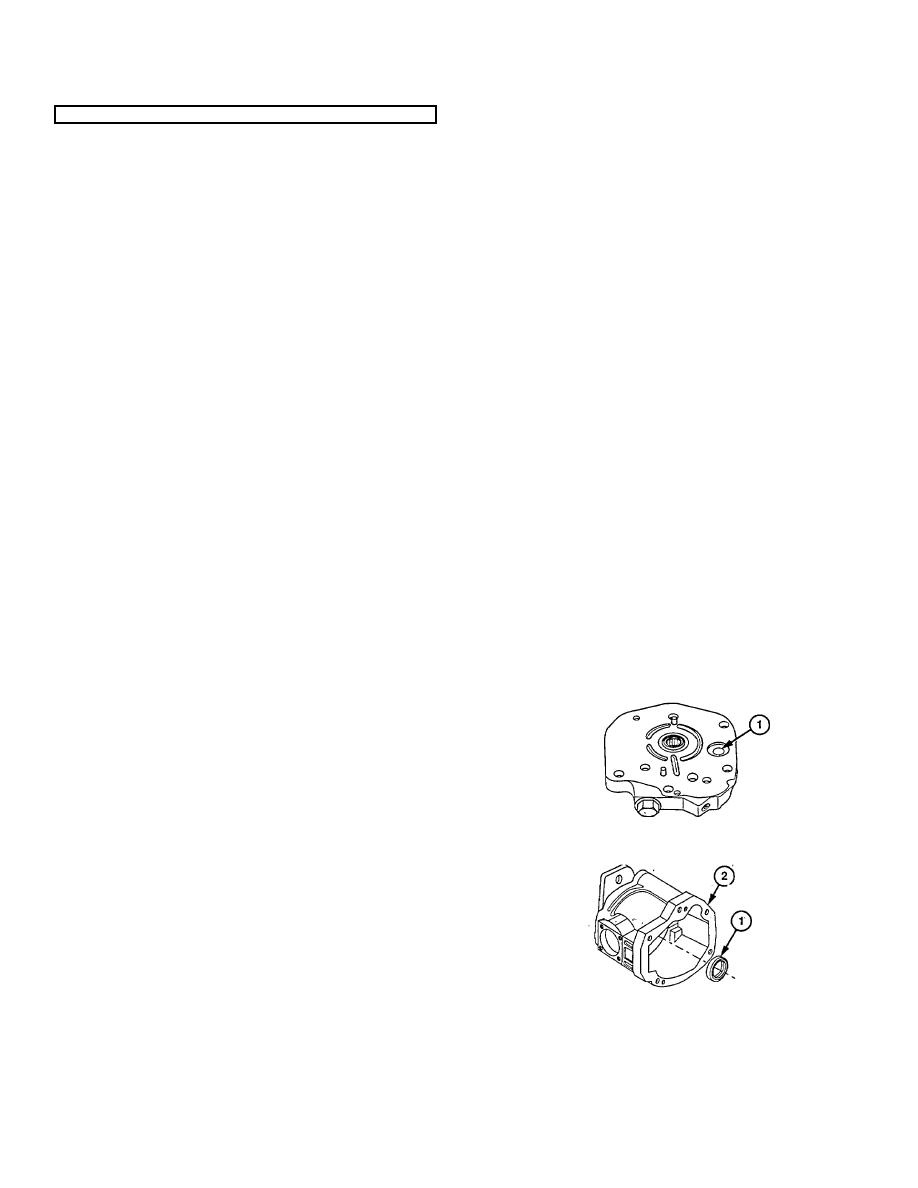

(15) Press in check valve (1 ). Valve should

return and hold firm against seat. Replace

if damaged.

(16) Inspect spherical washer for burrs, wear,

and scratches due to pin breakage.

c. Assembly

(1) Install new seal (1) in pump housing (2).

27-22.6

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |