|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2320-360-34-2

WARNING

Wear eye protection and use care

when removing retaining rings.

Retaining rings are under spring

tension and can act as projectiles

when released causing severe eye

injury.

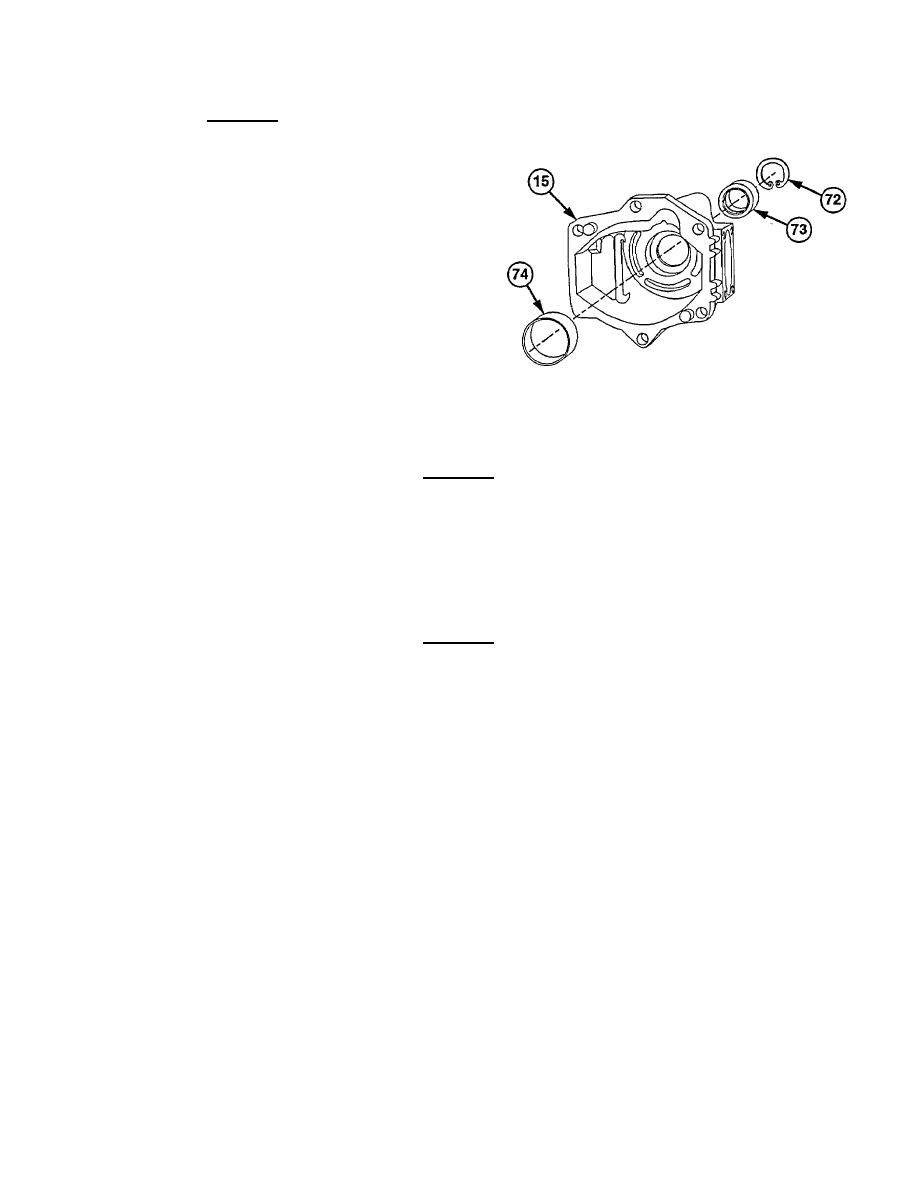

(37) Remove retaining ring (72) from housing

(15). Discard retaining ring.

(38) Remove seal (73) from housing (15).

Discard seal.

(39) Remove bearing race (74) from housing

(15).

c. Cleaning/Inspection

WARNING

Dry cleaning solvent P-D-680 Is toxic and flammable. Wear protective goggles and

gloves and use only in a well-ventilated area. Avoid contact with skin, eyes, and

clothes, and don't breathe vapors. Do not use near open flame or excessive heat.

The flash point is 100-138 F (38-59 C). If you become dizzy while using cleaning

solvent, get fresh air Immediately and get medical aid. If contact with eyes is

made, wash your eyes with water and get medical aid Immediately.

(1) Clean metal parts in dry cleaning solvent.

WARNING

Compressed air for cleaning purposes will not exceed 30 psi (207 kPa). Use only

with effective chip guarding and personal protective equipment (goggles/shield,

gloves, etc.)

CAUTION

Bearings must be air dried or damage to bearing will result.

(2) Dry parts, except bearings, with compressed air.

(3) Inspect parts for damage. Replace non-serviceable damaged parts. Remove all burrs with crocus cloth.

(4) Inspect face of wafer plate for wear, scratches, and fractures.

(5) Inspect springs for wear and check that ends are parallel. Replace warped or worn springs.

(6) Inspect yoke face for wear, roughness, and scoring.

(7) Inspect shaft for wear, chipped splines, and burrs.

NOTE

Wobble shoe plate to ensure that each piston is free within its bore in the cylinder

block

(8) Check cylinder block bore for excessive wear. Piston should be close fit but slide in and out easily. If

binding exists, clean and lubricate block and piston with dean hydraulic fluid. If binding persists, replace

cylinder block.

27-11

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |