|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2320-360-34-2

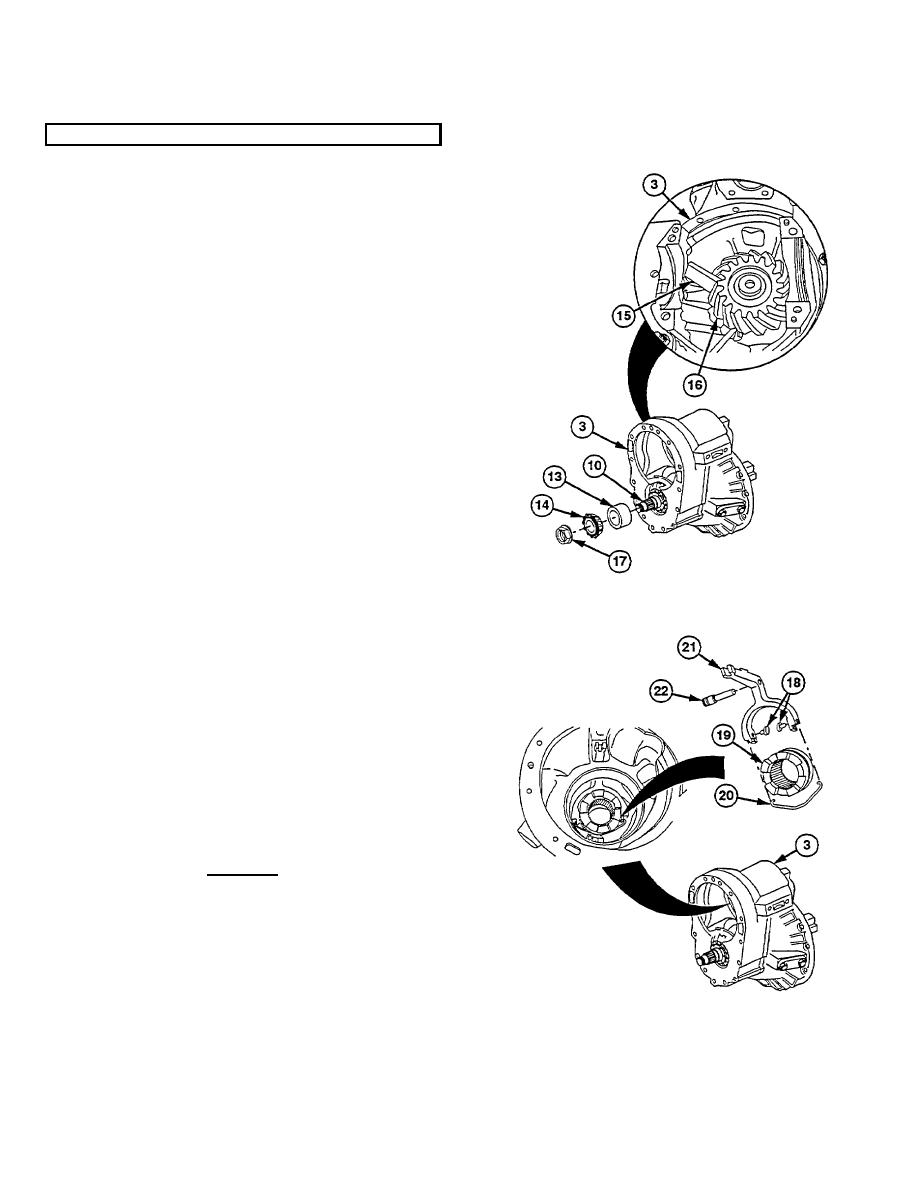

25-3. AXLE NO. 3 DIFFERENTIAL REPAIR (CONT)

(11) Position rear housing (3) so pinion shaft

(10) is parallel to floor.

(12) Install spacer (13) and taper bearing (14)

on pinion shaft (10) while assistant

supports pinion shaft (10).

(13) Position jet extractor (15) between gear

tooth on pinion gear (16) and housing (3)

with aid of assistant

(14) Install new pinion nut (17) on pinion shaft

(10). Torque to 543-572 lb-ft (736-776

Nm).

(15) Stake edges of nut (17) in notches of shaft

(10).

(16) Remove jet extractor (15) from housing

(3).

NOTE

Assembled pinion gear should rotate

(4.45.4 N m) of

with 38-47 lb-in.

torque. Repeat assembly steps (4)

thru (14) if over these limits.

(17) Check rolling resistance of assembled

gear by turning pinion nut (17).

(18) Install two shift dogs (18), dutch gear (19),

and retaining dip (20) on fork (21).

(19) Install assembled fork (21) and pin (22) in

rear housing (3).

(20) Lock pin (22) in place by staking three

points.

WARNING

On direct contact, uncured silicone

sealant Irritates eyes.

In case of

contact, flush eyes with water and

seek medical attention. In case of

skin contact, wipe off and flush with

water.

(21) Coat pin (22) area with layer of silicone

adhesive-sealant.

25-46

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |