|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2320-360-34-2

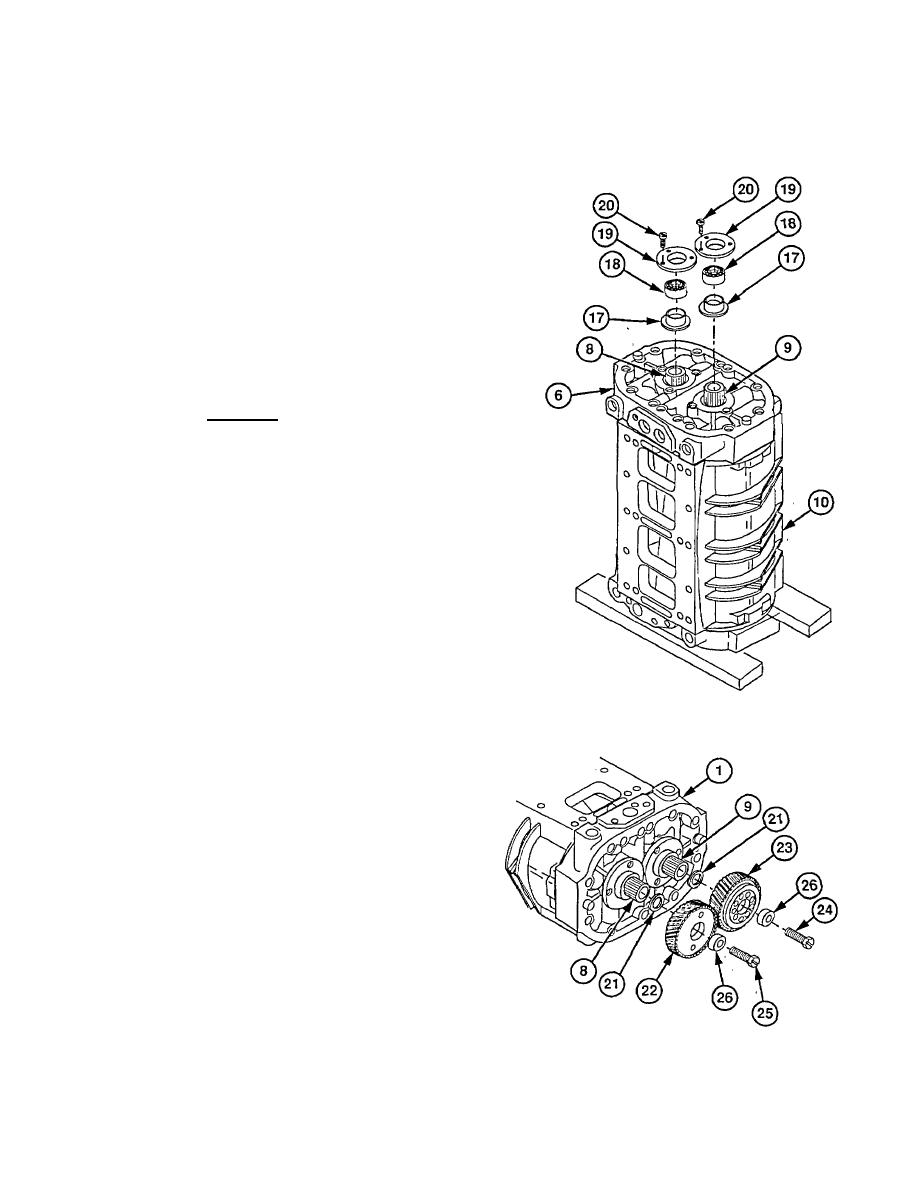

(20) Turn blower (10) over on wooden blocks so front

end plate (6) faces up.

(21) Install two bearing collars (17) on rotors (8 and

9).

(22) Coat two roller bearings (18) with lubricating oil.

(23) Install roller bearings (18) over rotors (8 and 9)

and in front end plate (6).

NOTE

Flanges on reflectors face front end

plate.

(24) Install two reflectors (19) on front end plate (6)

with six screws (20). Torque to 84-108 lb-in.

(9.5-12.2 Nm).

WARNING

Do not place fingers between rotors.

Turning rotors may cause serious

Injury.

(25) Position blower (10) bottom down with rear end

plate (1) facing you.

NOTE

Timing mark (located at flat spot) in

end of each rotor shaft will aid in

aligning rotors and gears.

(26) Set rotors (8 and 9) so that flat spots on splines

are in line with each other and facing left.

NOTE

Folded shop towel should be placed

between rotor lobes to keep rotors

from turning.

(27) Install two spacers (21) on two rotors (8 and 9).

(28) Coat splines of rotors (8 and 9) with lubricating

oil.

(29) Install both timing gears (22 and 23) on rotors (8

and 9) at the same time so that flat spots in gear

splines align with flat spots in rotor splines.

(30) Coat screws (24 and 25) with lubricating oil.

(31) Install two spacers (26) and screws (24 and 25)

in timing gears (22 and 23).

NOTE

Screws must be tightened evenly to

draw both timing gears tight.

(32) Tighten screws (24 and 25) to 110 lb-ft (149

Nm).

20-11

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |