|

|||

|

|

|||

|

Page Title:

MAIN BEARING AND CRANKSHAFT REPAIR (CONT) |

|

||

| ||||||||||

|

|

TM 9-2320-360-34-2

19-8.

MAIN BEARING AND CRANKSHAFT REPAIR (CONT)

NOTE

Align dowel pin on crankshaft with

hole in gear.

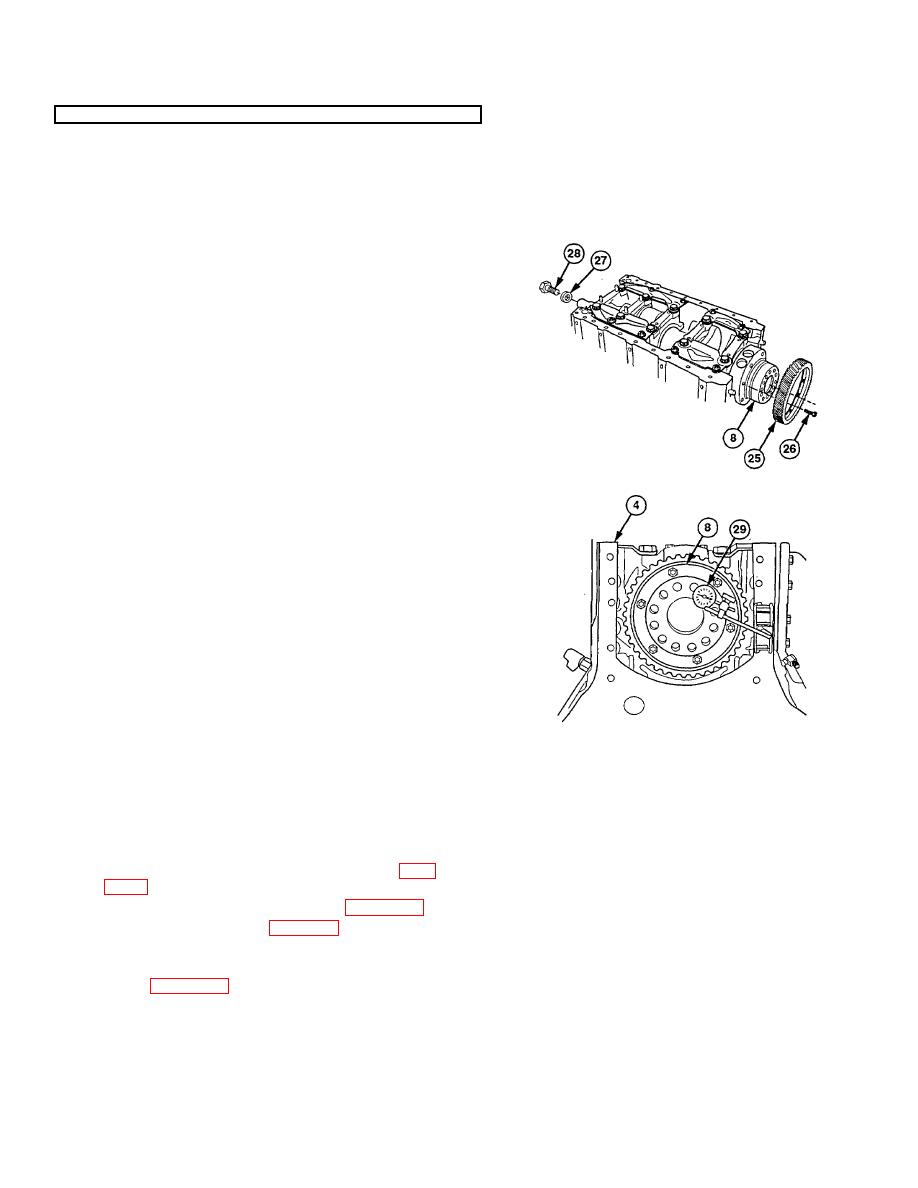

(39) Install timing gear (25) on crankshaft (8) with six

screws (26).

(40) Install spacer (27) and screw (28) on end of

crankshaft (8).

(41) Hold screw (28) while assistant torques six

screws (26) to 40 lb-ft (54 Nm).

(42) Remove screw (28) and spacer (27) from

crankshaft (8).

(43) Install dial indicator (29) on engine block (4).

(44) Adjust dial indicator to zero while assistant

pushes crankshaft (8) toward indicator (29) with

pry bar.

(45)

Read end play while assistant pushes

crankshaft away from dial indicator (29) with pry

bar. Minimum end play is 0.004 in. (0.10 mm)

and maximum end play is 0.018 in. (0.46). If

end play is outside limits, replace crankshaft (8).

d. Follow-On Maintenance

(1) Install pistons, connecting rods, and liners (para

(2) Install camshafts and end bearings (para 19-12).

(3) Install flywheel housing (para 19-9).

(4) Install flexplate assembly (para 3-17).

(5) Install crankshaft cover, front oil seat, and oil

pump (para 19-14).

19-70

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |