|

|||

|

|

|||

|

Page Title:

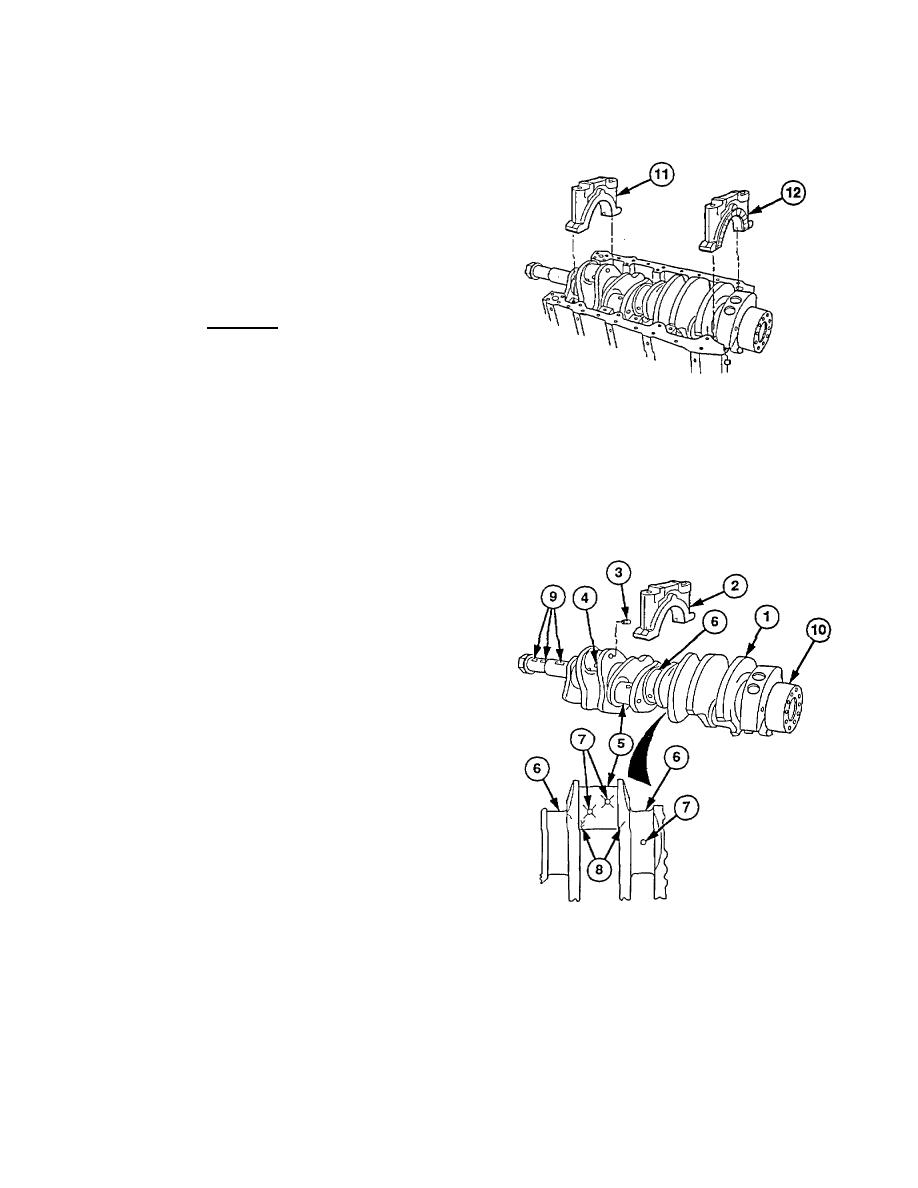

MAIN BEARING AND CRANKSHAFT REPAIR (CONT) |

|

||

| ||||||||||

|

|

TM 9-2320-360-34-2

(34)

Install two main bearing caps (11 and 12).

(35)

Do steps (9) thru (11).

(36) Repeat steps (1 7) and (18). If crankshaft runout

is still too high, replace crankshaft (2).

(37) Do steps (19) thru (25).

b. Cleaning/inspection

WARNING

Fuel Is very flammable and can

explode easily.

To avoid serious

Injury or death, keep flame away from

fuel and keep fire extinguisher within

easy reach when working with fuel.

Do not work on fuel system when

engine Is hot. Fuel can be Ignited by

hot engine. When working with fuel,

post signs that read NO SMOKING

WITHIN 50 FEET oil vehicle.

(1) Clean crankshaft (1) and bearing caps (2) with

dean diesel fuel and a lint-free cloth.

(2) Remove four plugs (3) from crankshaft (1).

(3) Flush oil passages (4) in crankshaft (1) with stiff

wire brush.

(4) Install four plugs (3) on crankshaft (1). Torque

to 120-144 lb-in. ( 13.6-16.3 Nm).

(5) Visually inspect crankshaft (1) for signs of

scoring, grooving, or overheating.

(6) Inspect crankshaft connecting rod journals

(5) and main bearing journals (6) for deep

scratches. Replace crankshaft (1) if damaged.

(7) Inspect connecting rod journals (5) and main

bearing journals (6) for signs of cracks at journal

oil holes (7) or joining points (8) of connecting

rod journal (5) and main bearing journals (6).

Replace crankshaft (1) if damaged.

(8) Inspect cranksha ft keyways (9) for signs of

cracks or wear.

Replace crankshaft (1) if

damaged.

(9) Inspect rear oil seal contact surface (10) for

deep scratching.

If scratches cannot be

smoothed out with crocus cloth, replace

crankshaft.

19-63

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |