|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2320-36034-2

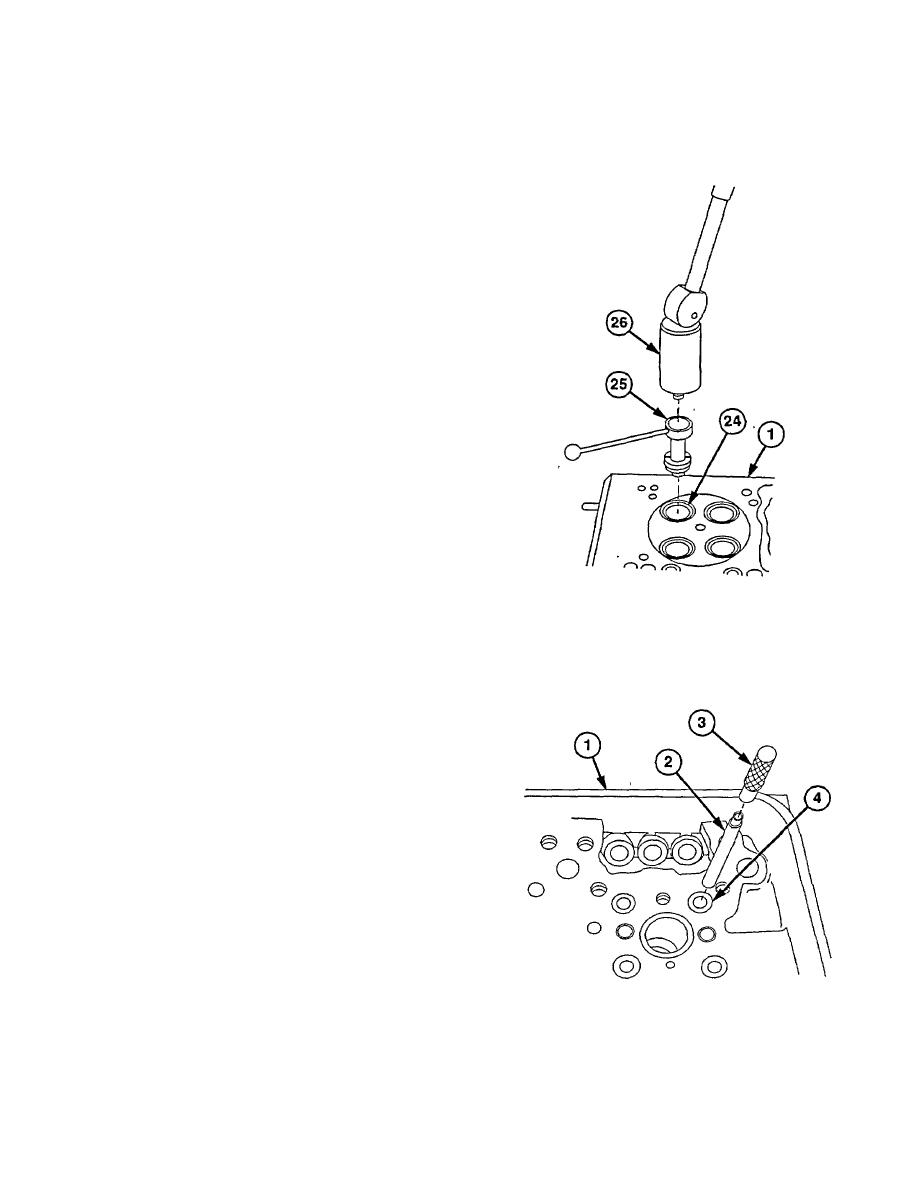

(36) Inspect valve seat inserts (24) for excessive or

uneven wear, pitting, or cracks.

NOTE

Worn or pitted valve seat inserts

that are not severely damaged may

be repaired by refacing.

Do steps (37) thru (39) to remove

valve seat inserts that failed

inspection and cannot be refaced.

(37) Position collet (25) flush with bottom of valve

seat insert (24).

(38) Press handle (26) down and remove valve seat

insert (24) from cylinder head (1).

(39) Measure diameter of valve seat insert

counterbore in cylinder head (1).

Replace

cylinder head (1) if measurement is not between

1.440 in. (36.576 mm) and 1.441 In. (36.601

mm).

e. Assembly

NOTE

Do steps (1) thru (5) if valve guides

were removed.

(1) Place cylinder head (1) in press with top facing

up.

(2) Install internally threaded end of valve guide (2)

in guide installer (3).

(3) Position valve guide (2) squarely on guide bore

(4) in cylinder head (1).

(4) Press guide installer (3) gently to start valve

guide (2) In straight.

(5) Press valve guide (2) until guide installer (3)

contacts bottom of counterbore in cylinder head

(1).

19-47

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |