|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2320-360-34-2

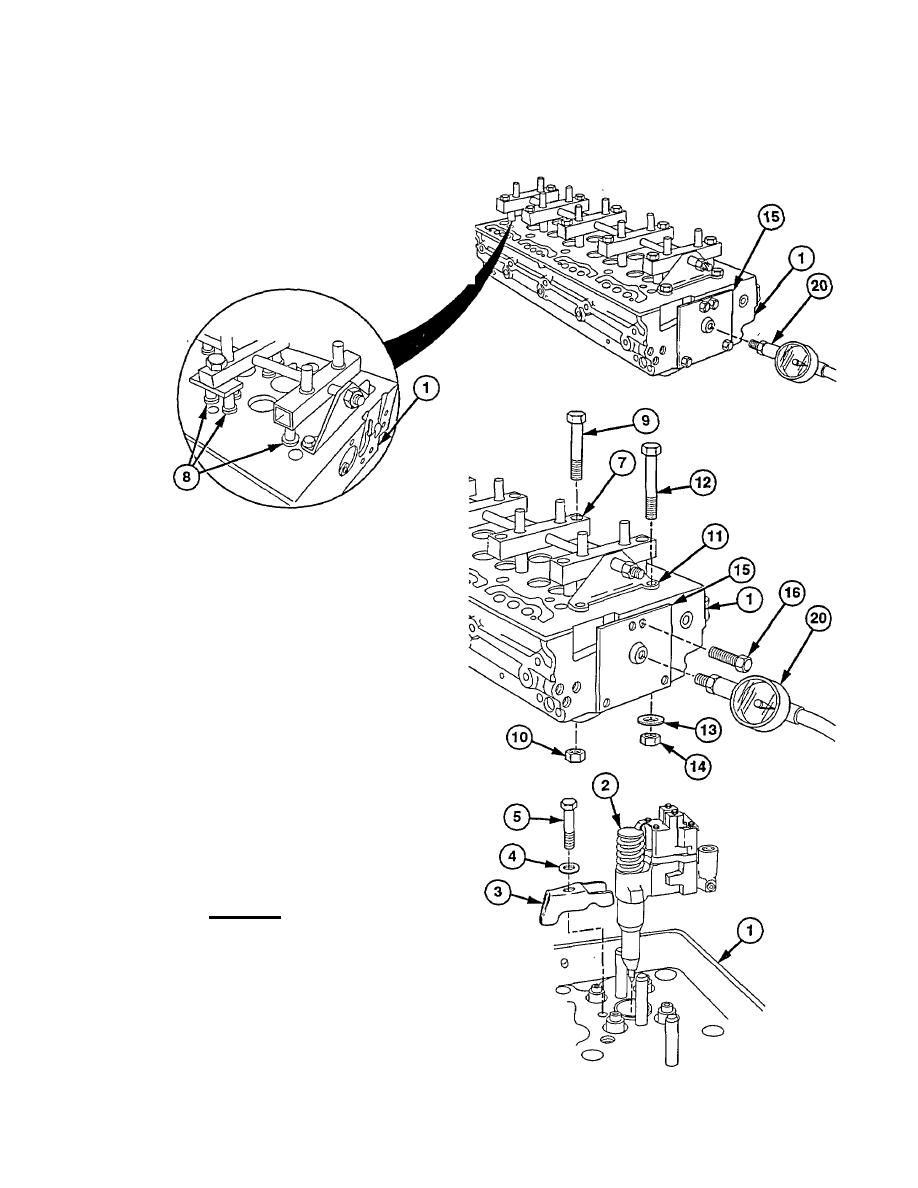

(9) Install air hose (20) on end plate (15) and apply

40 psi (276 kPa) to cylinder head (1).

(10) Check for air leaks with soap solution around

eight water nozzles (8) and bottom of cylinder

head (1) with soap solution.

(11) Check for air leaks with soap solution at top and

bottom of injector tubes, oil galleys, exhaust

ports, fuel manifolds, and top and bottom of

cylinder head (1).

(12) Slowly relieve air pressure and remove air

supply.

(13) Loosen air hose (20) from end plate (15) to allow

air pressure to escape.

(14) Remove air hose (20) from end plate (15).

(15) Remove six nuts (10), screws (9), four screws

(12), washers (13), nuts (14), two tie down

plates (11), and test fixture (7) from cylinder

head (1).

(16) Remove three screws (16) and end plate (15)

from cylinder head (1).

(17) Remove four injectors (2), screws (5), washers

(4), and clamps (3) from cylinder head (1).

WARNING

Compressed

air

for

cleaning

purposes will not exceed 30 psi (207

kPa). Use only with effective chip

guarding and personal protective

equipment (goggles/shield, gloves,

etc.).

(18) Dry cylinder head (1) with compressed air.

19-41

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |