|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2320-360-34-2

19-7. CYLINDER HEAD REPAIR (CONT)

NOTE

Cylinder head must be pressure

tested before cylinder head repair.

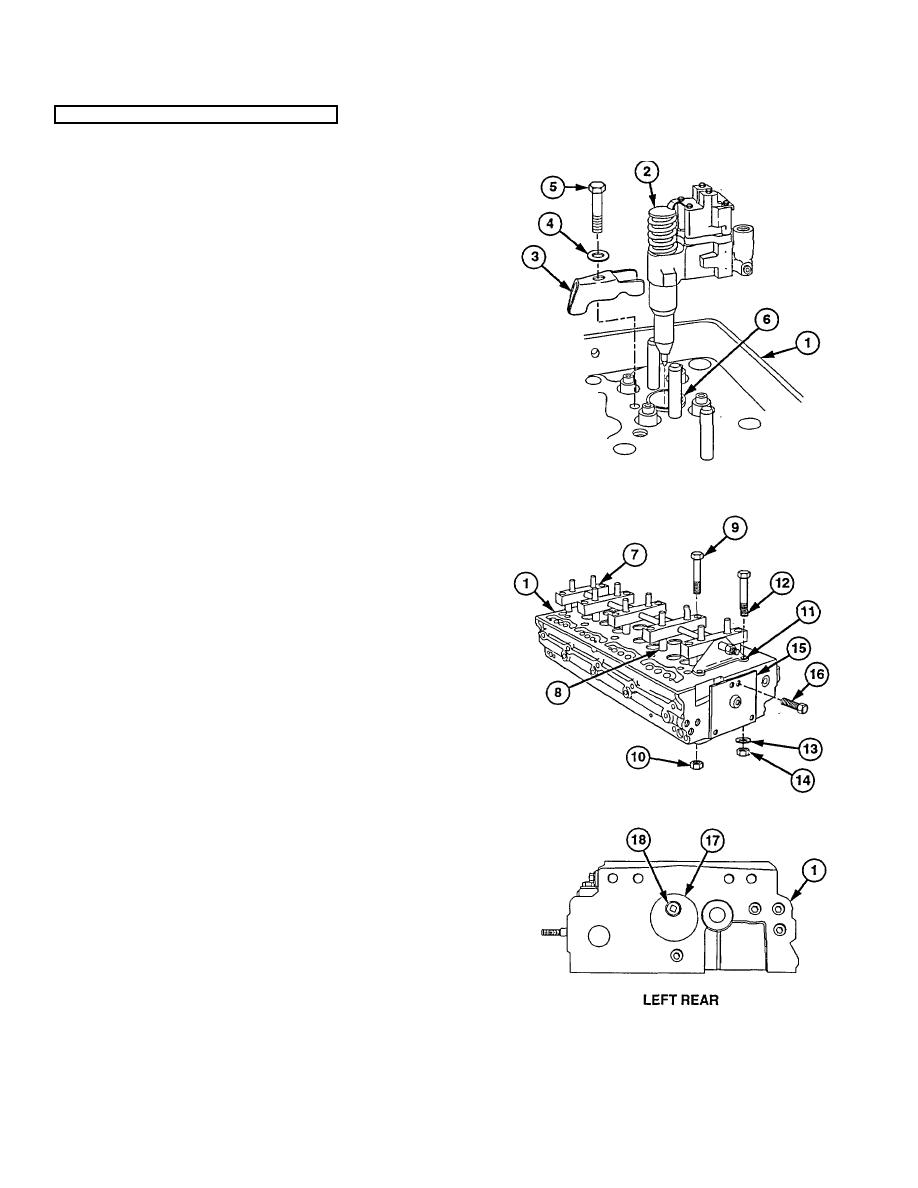

(2) Install four injectors (2), clamps (3), washers (4),

and screws (5) in injector tubes (6). Torque to

240-300 lb-in. (27.1-33.9 N m).

(3) Position cylinder head (1) so bottom faces up.

(4) Align test fixture (7) on bottom of cylinder head

(1) so rubber stoppers cover water nozzles (8).

CAUTION

Do not overtighten hold-down cap

screws.

Rubber stopper could

distort enough to seal off outer

diameter of water nozzle.

A leak

would not be detected from outer

diameter. Damage to equipment may

result.

(5) Install six screws (9) and nuts (10) on test fixture

(7). Torque to 48-60 lb-in. (7-8 N m).

(6) Install two tie down plates (11) on cylinder head

(1) with four screws (12), washers (13), and nuts

(14).

(7) Install end plate (15) on thermostat end of

cylinder head (1) with three screws (16).

(8) Install rear plug (17) and pipe plug (18) in left

rear of cylinder head (1).

19-40

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |