|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2320-360-34-2

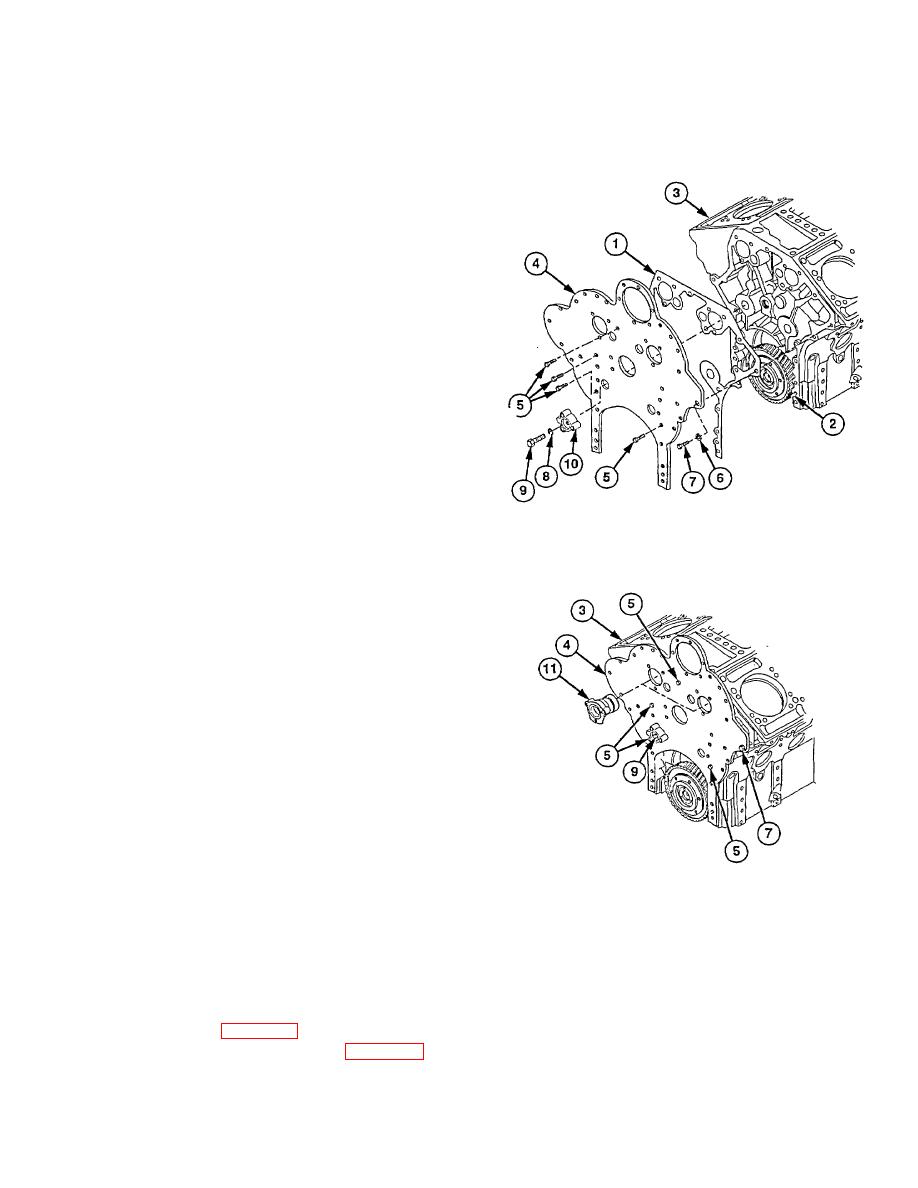

d. Installation

(1) Coat new gasket (1) with grease and Install over

dowels (2) onto engine block (3).

(2) Install rear end plate (4) on dowels (2).

(3) Position four screws (5) on rear end plate (4).

Do not tighten.

(4) Position new lockwasher (6) and screw (7) on

rear end plate (4). Do not tighten.

NOTE

Special washer is installed in same

position as noted during removal.

(5) Install special washer (8) on screw (9) with

grooved side facing head of screw (9).

NOTE

Align dowel in dummy hub with hole

in rear end plate.

(6) Install dummy hub (10), special washer (8), and

screw (9) on rear end plate (4).

NOTE

Camshaft

end

bearings

are

temporarily installed to align rear

end plate.

Holes in front and rear end plates

for camshaft end bearings are not

the same size. Smaller hole is

accurately machined for alignment

purposes and is always located on

right side of engine as viewed

from the rear.

(7) Install two camshaft end bearings (11) in rear

end plate (4) and engine block (3).

(8) Tighten four screws (5) to 31-35 lb-f (41-47

Nm).

(9) Tighten screw (7) to 103-110 lb-ft (140-149

Nm).

(10) Tighten screw (9) to 90 lb-ft (122 Nm).

(11) Remove two end bearings (11) from rear end

plate (4) and engine block (3).

e. Follow-On Maintenance

(1) Install Idler gear (para 19-13).

(2) Install camshafts and end bearings (para 19-12).

(3) Install blower drive support (para 4-8).

19-33

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |