|

|||

|

|

|||

|

Page Title:

ENGINE BLOCK REPAIR (CONT) |

|

||

| ||||||||||

|

|

TM 9-2320-360-34-2

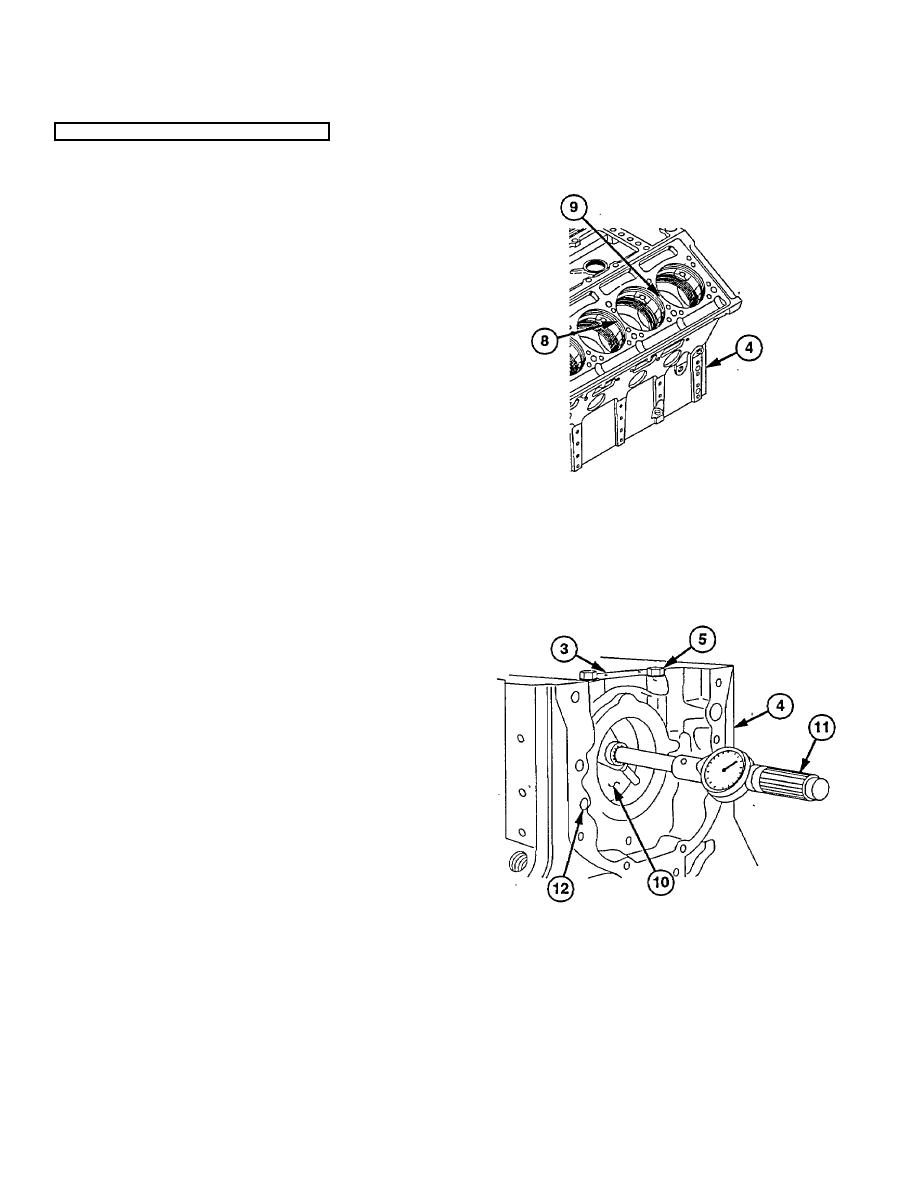

19-4. ENGINE BLOCK REPAIR (CONT)

NOTE

Cylinders may be counterbored to

either of two depths.

(15) Measure depth of counterbore (8) using depth

gage. If depth is not between 0.4755 In. (12.13

mm) and 0.4770 In. (12.12 mm) or between

0.4905 in. (12.50 mm) and 0.4920 in. (12.50

mm) and cannot be brought into limits by

installing cylinder liner insert, replace engine

block (4).

(16) If counterbore (8) varies more than 0.0015 in.

(0.04 mm) around edge of cylinder, replace

engine block (4).

NOTE

If two adjacent cylinders have

different counterbore depth ranges

measured in step (15) above, step

(17) does not apply.

(17) If difference between any one adjacent cylinder

counterbore (8) measured at their closest point

(9) is more than 0.0015 in. (0.04 mm), replace

engine block (4).

(18) Measure each main bearing bore (10) diameter

with bore gage (11). If main bearing bore

diameter is less than 4.812 in. (122.22 mm) or

greater than 4.813 in. (122.25 mm) replace

engine block (4).

(19) Remove five main bearing caps (3) and screws

(5) from engine block (4).

(20) Inspect dowel holes (12) In engine block (4) for

oversized holes or damage. Replace engine

block if damaged or oversized.

(21) Inspect threaded holes for stripped or crossed

threads. Use a tap to clean threads.

(22) Inspect machined surf aces for flatness, burrs,

and scratches. If surfaces cannot be cleaned by

lapping, replace engine block (4).

19-16

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |