|

| |

TM 9-2320-360-34-1

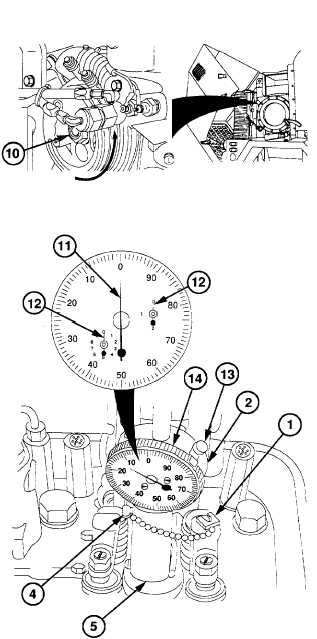

(3)

Turn

camshaft

(10)

slowly

counterclockwise until large dial hand (11)

starts moving.

(4)

Continue turning camshaft (10) slowly

counterclockwise until large dial hand (11)

stops moving.

(5)

Turn camshaft (10) slowly in opposite

direction until large dial hand (11) barely

starts to move. Piston is now at top-dead

center.

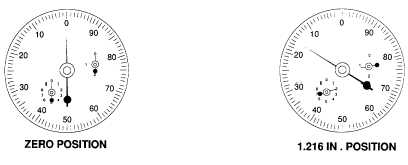

NOTE

Dial indicator must be zeroed before

piston

downward

travel

can

be

measured. Do steps (6) thru (8) to

zero dial indicator.

(6)

Loosen clamp screw (4) and remove

slotted spacer (1).

(7)

Lower timing tool (5) until two small dial

hands (12) are at zero and the large dial

hand (11) is near zero. Tighten clamp

screw (4).

(8)

Loosen bezel screw (13) and rotate outer

ring (14) of dial until zero lines up with

large dial hand (11). Tighten bezel screw

(13).

CAUTION

If pulley loosens during procedure,

tighten to torque values specified in

para 19-12. Failure to comply may

result in loss of crankshaft pulley and

possible engine damage.

(9)

Zero dial indicator (2) and turn camshaft

(10) slowly counterclockwise, until dial

indicates exactly 1.216 in. (30.89 mm).

3-63

|