|

| |

TM 9-2320-360-34-1

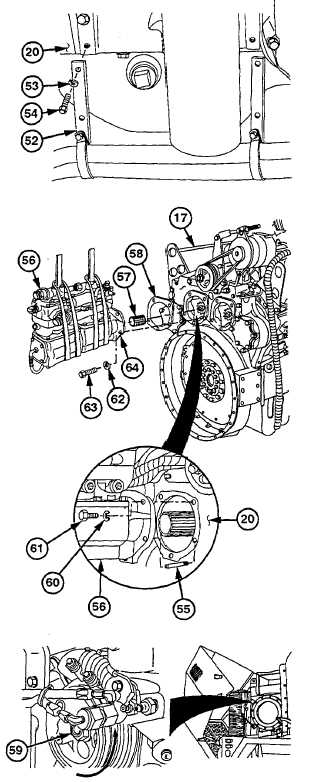

3-5. ENGINE REPLACEMENT (CONT)

(23)

Install brackets (52) on engine (20) with

two new lockwashers (53) and screws

(54).

(24)

Install two guide screws (55) into lower

holes of engine (20).

WARNING

Air

compressor

weighs

approximately

100

lb

(45

kg).

Properly

support

air

compressor

during Installation. Failure to comply

may result in serious personnel

Injury.

(25)

Attach

suitable

lifting

device

to

air

compressor (56).

(26)

Position air compressor (56) on guide

screws (55) with aid of assistant.

WARNING

Sealing compound can burn easily,

can give off harmful vapors, and are

harmful to skin and clothing. To

avoid injury or death, keep away from

open fire and use in well-ventilated

area. If sealing compound gets on

skin or clothing, wash immediately

with soap and water.

CAUTION

Drive coupling must be aligned with

drive gears on engine. Failure to

comply may result in equipment

damage.

NOTE

Air compressor and mating surfaces

on engine must be clean. Rubber

seal on gasket must face away from

engine.

(26.1)

Apply sealing compound to engine side of

new gasket (58).

(27)

Install drive coupling (57) and gasket (58)

on air compressor (56) while assistant

turns camshaft pulley (59).

(28)

Position air compressor (56) on engine

(20) with two new lockwashers (60) and

screws (61) with aid of assistant.

(29)

Remove two guide screws (55) and

position two new lockwashers (62) and

screws (63) in lower holes of compressor

mounting flange (64).

(30)

Remove lifting device from air compressor

(56).

(31)

Tighten four screws (61 and 63) to 73-83

lb-ft (99-113 Nm).

3-56 Change 1

|