|

| |

TM 9-2320-356-BD

Procedural Steps:

Option 1:

Splice with Terminal Lug.

1.

Clean area to be repaired.

2.

Trim the broken ends of the wire and slide an insulating sleeve or shrink

tubing over one end of the wire.

3.

Strip wire and crimp an insulated terminal lug to each wire end.

8-14.

HEAVY-DUTY CABLE DAMAGED

General Information:

Heavy electrical cables are more difficult to repair than small wires; however,

they can be repaired using several different methods. Splicing procedures can be

used to repair a break.

Limitations:

o None

Personnel/Time Required:

o 1 soldier

o 15 - 60 minutes

Materials/Tools:

o Terminal lugs, screw

clamp, or small hole clamp

o Insulating sleeve or

electrical tape

o Soldering iron or torch

and solder

o Safety wire

o Clamp cable

o Heat shrink tubing

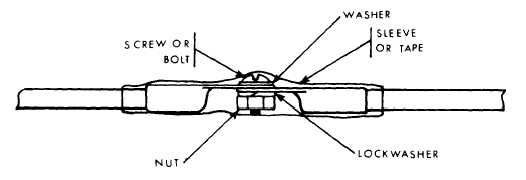

4.

Bolt the terminal lugs together using short bolt with nut.

5.

Slide the sleeve or tubing over the connection or use tape to insulate the

conductor.

Apply heat to shrink tubing.

Ends of nonshrink sleeve must be tied.

6.

Record the BDAR action taken.

When the mission is completed, as soon as

practicable, repair using standard maintenance procedures.

8-14

|